A nylon zipper forming machine center line lack of material automatic stop device

A technology of automatic shutdown and forming machine, applied in fastener components, other household appliances, household appliances, etc., can solve the problems of occupying employees' working time, zipper without central wire, and inability to transmit signals, so as to avoid material waste and work. The effect of stable state and avoiding a large number of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

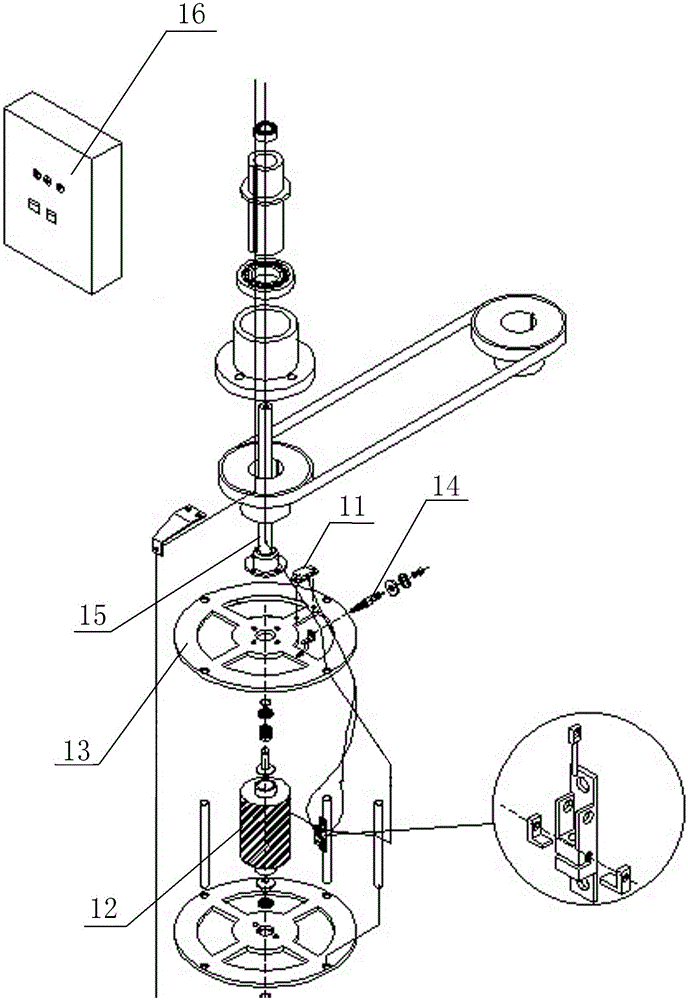

[0009] The present invention will be further described below with reference to the accompanying drawings.

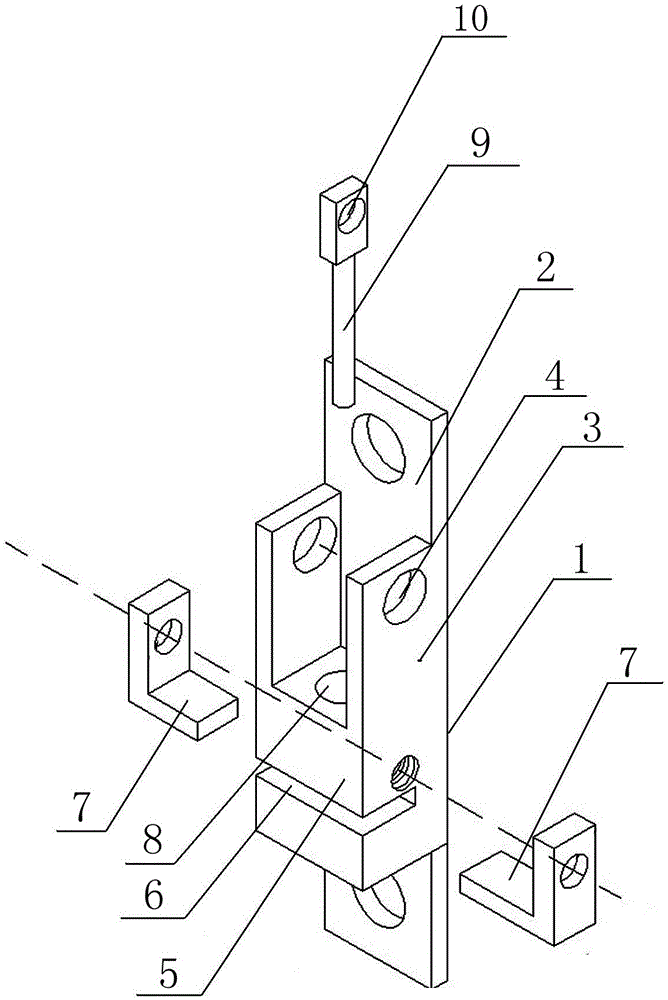

[0010] The present invention is a nylon zipper forming machine center line lack of material automatic stop device, such as figure 1 As shown in , it mainly includes an induction seat 1, which is characterized in that: the induction seat 1 is provided with a back plate 2, the two sides of the back plate 2 are respectively provided with side baffles 3, and the two side baffles 3 are respectively provided with There is a threading hole 4, the bottom of the back plate 2 and the two side baffles 3 form a base 5, the base 5 is horizontally provided with a notch 6, the notch 6 runs through the base 5 horizontally, and the openings at both ends of the notch 6 are respectively provided with There is a contact piece 7, a gap is formed in the notch 6 between the two contact pieces 7, a vertical hole 8 is formed at the base 5 on the upper part of the notch 6, and a sensing rod 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com