Driving device

A driving device and generating device technology, which is applied in the direction of office printing equipment, printing, electrical components, etc., can solve the problems of increased transportation costs, increased packaging costs, and the inability to effectively use the internal space of the transport box, etc., to achieve shortening Necessary time, damage prevention, and the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

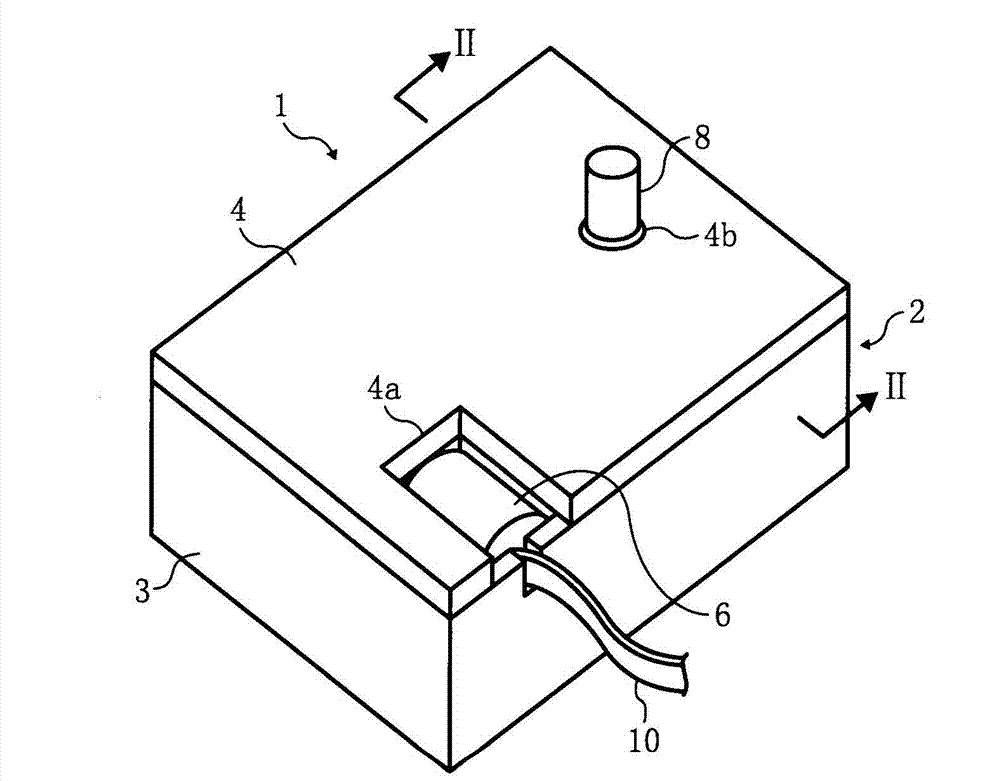

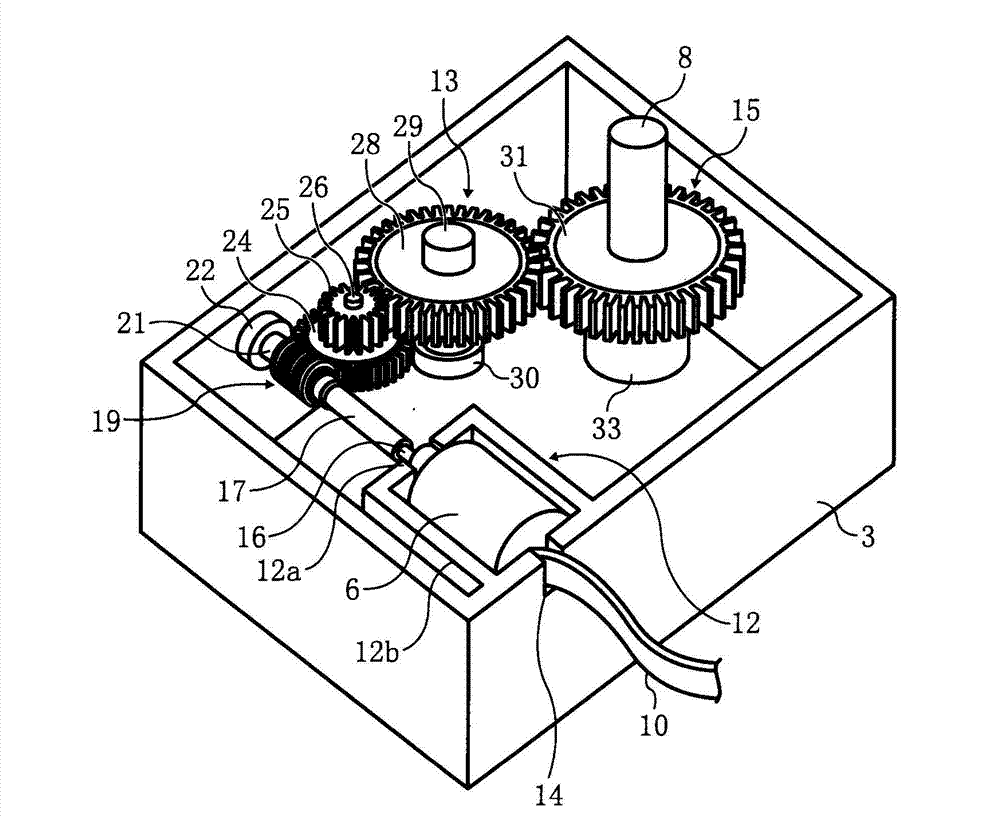

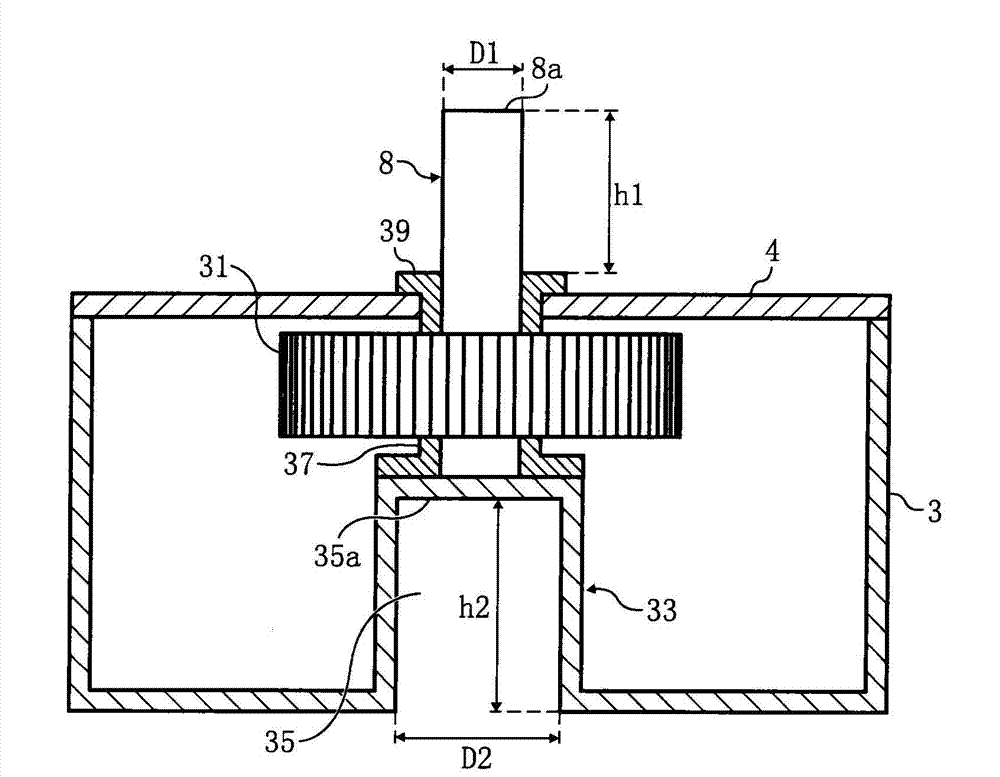

[0082] Below, refer to Figure 1-Figure 14 Embodiments of the present invention will be described.

[0083] The driving device 1 according to the first embodiment of the present invention is as figure 1 and figure 2 As shown, a frame body 2, a motor 6 housed in the frame body 2 and used as a rotational power generating device for generating rotational power, and a motor 6 that is housed in the frame body 2 and used to transmit the rotation of the motor 6 are provided. The speed reducer 13 of the rotary power transmission mechanism of power, and the output gear 15 of the rotary power output mechanism which is accommodated in the frame 2 and outputs the rotary power transmitted from the above-mentioned speed reducer 13. The driving device 1 is formed in a size to be incorporated in an automobile, an OA machine, or the like.

[0084] The frame body 2 includes a cover plate 4 as one side of the frame body 2 and a body portion 3 as the other side of the frame body 2, and is for...

no. 2 approach

[0108] Next, referring to Figure 5- Figure 7 A second embodiment of the driving device 1 according to the present invention will be described. In addition, the code|symbol is attached|subjected to the same part as the said embodiment, and description is abbreviate|omitted.

[0109] In the driving device 1 according to the second embodiment of the present invention, as shown in FIG. The locking pieces 44 , 45 in the aforementioned pair of locking holes 41 , 42 . The motor 6 is embedded in the frame body 2 .

[0110] The locking holes 41 and 42 are provided on concentric circles of the output shaft 8 , and are formed in fan shapes symmetrical to each other with respect to the output shaft 8 . The locking holes 41 , 42 and the locking pieces 44 , 45 are in opposite directions relative to each other along the axial direction of the output shaft 8 after overlapping the plurality of frames 2 along the axial direction of the output shaft 8 . When rotating, the aforementioned loc...

no. 3 approach

[0124] Next, referring to Figure 8- Figure 11 A third embodiment of the driving device 1 according to the present invention will be described. In addition, the code|symbol is attached|subjected to the same part as the said embodiment, and description is abbreviate|omitted.

[0125] In the drive device 1 according to the third embodiment of the present invention, as shown in FIG. 8 , a pair of locking portions 48 and 49 are provided in the cover portion 4 . In the main body part 3, the locking pieces 44, 45 which are locked to the aforementioned pair of locking parts 48, 49 are protrudingly provided from the main body part 3 to the outside, and the locking pieces 44, 45 are protruded from the main body part 3 to the outside and are connected to the inner side. A pair of abutting protrusions 52, 53 that abut the cover portion 4. The motor 6 is embedded in the frame body 2 .

[0126] The locking parts 48 and 49 are formed in a frame shape, and include two bottom end parts ere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com