Toner and developer

A toner and colorant technology, applied in the field of developer and toner, can solve the problems of inability to obtain the excellent separation ability of toner, insufficient effect, printing paper wrapping around the fixing roller, etc., and achieve excellent low-temperature fixing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

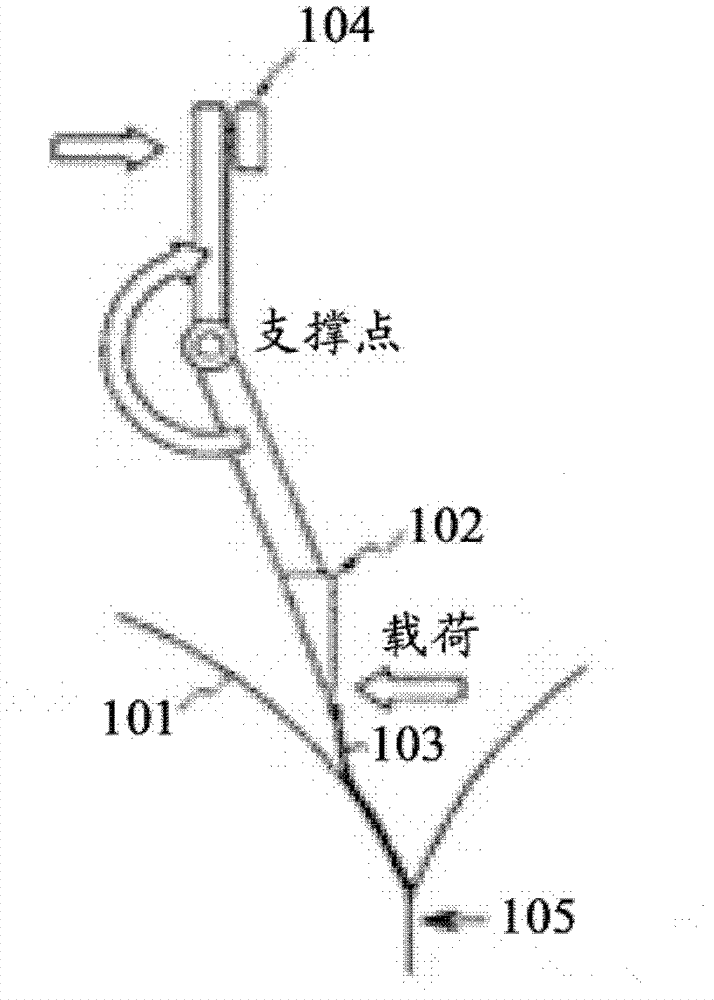

Image

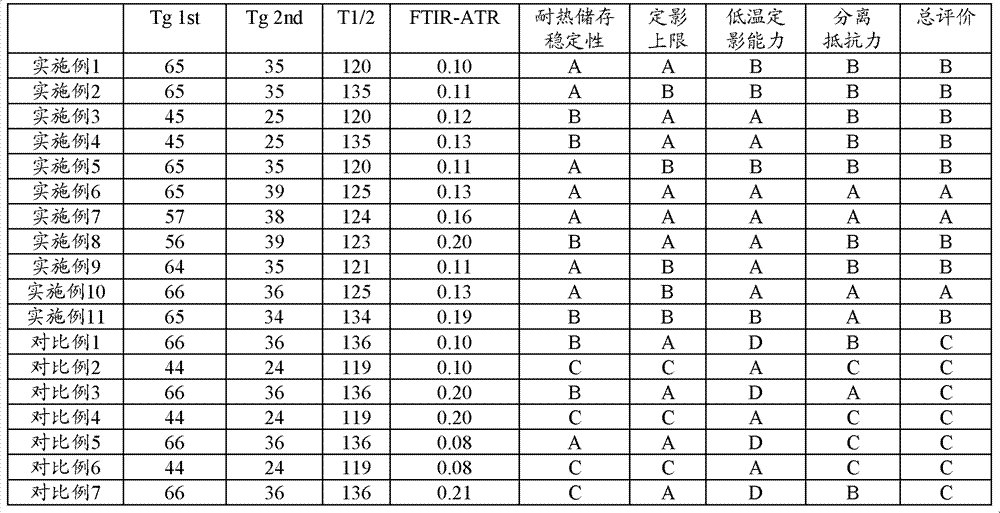

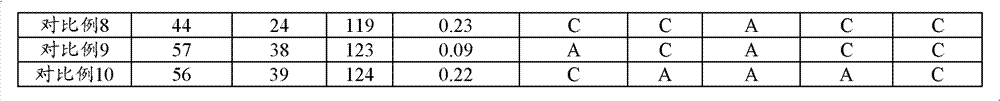

Examples

Embodiment 1

[0366]

[0367] After filtering 100 parts of the dispersion slurry 1 under reduced pressure, the resultant was subjected to a series of the following treatments (1)-(4) twice, thereby producing a filter cake 1:

[0368] (1) Add ion-exchanged water (100 parts) to the filter cake, then use a TK homomixer (10 minutes at 12000 rpm) to mix, and then filter;

[0369] (2) 10% aqueous sodium hydroxide solution (100 parts) was added to the filter cake obtained in (1), followed by mixing using a TK homomixer (at 12000 rpm for 30 minutes), and then filtering under reduced pressure;

[0370] (3) 10% by mass hydrochloric acid (100 parts) was added to the filter cake obtained in (2), followed by mixing using a TK homomixer (10 minutes at 12000 rpm), and then filtering; and

[0371] (4) Ion-exchanged water (300 parts) was added to the filter cake obtained in (3), followed by mixing using a TK homomixer (at 12000 rpm for 10 minutes), followed by filtration.

[0372] Cake 1 was dried at 45°...

Embodiment 2

[0374] Toner 2 of Example 2 was obtained in the same manner as in Example 1, provided that dispersion slurry 2 was used instead of dispersion slurry 1 .

Embodiment 3

[0376] Toner 3 of Example 3 was obtained in the same manner as in Example 1, provided that dispersion slurry 3 was used instead of dispersion slurry 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com