Polarity-reversal signal converting method and device and display

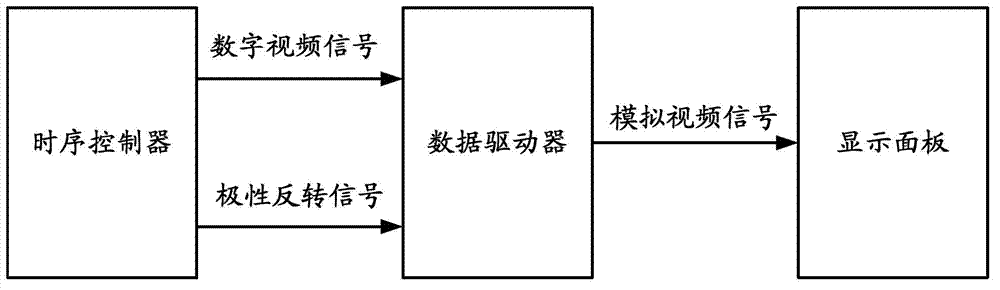

A signal conversion device and polarity reversal technology, applied in static indicators, instruments, etc., to achieve the effect of flexible and changeable driving methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

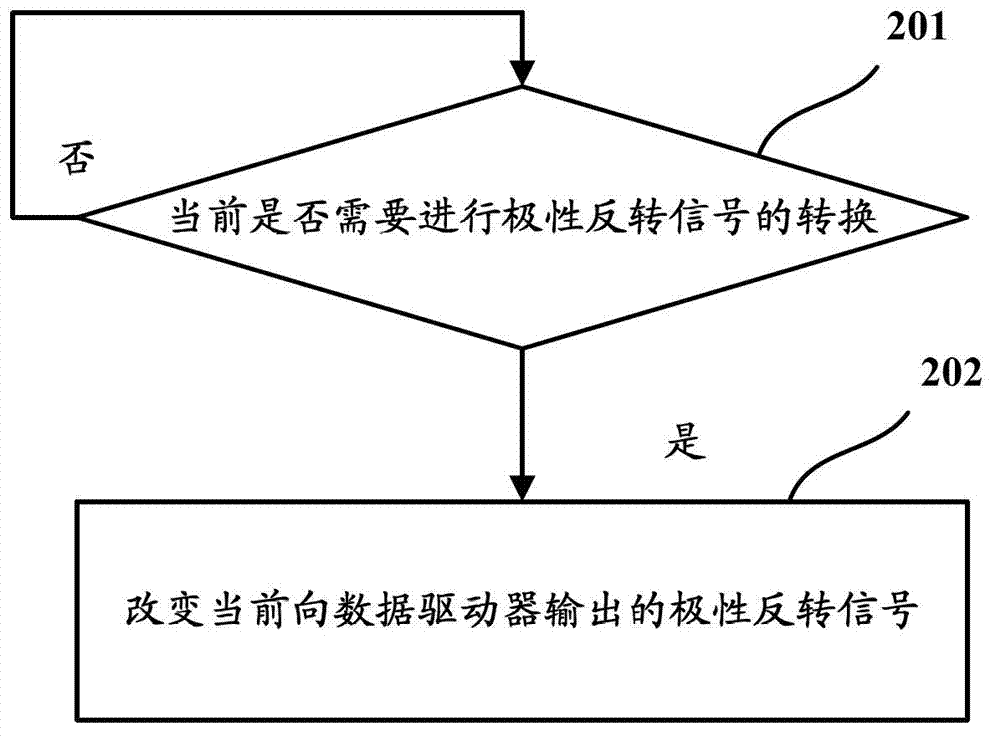

[0044] Such as figure 2 Shown is a schematic flowchart of a polarity inversion signal conversion method according to Embodiment 1 of the present invention, and the polarity inversion signal conversion method includes the following steps:

[0045] Step 201, judging whether it is necessary to convert the polarity inversion signal at present, if yes, execute step 202, otherwise, continue to execute step 201;

[0046] Step 202, changing the current polarity inversion signal output to the data driver.

[0047] Through the method provided by the above embodiments, the polarity inversion signal provided to the data driver can be changed according to different situations, so that the driving mode of the data driver is more flexible and changeable.

[0048] The first embodiment above will be described in detail below with an example.

[0049] The existing timing controller usually drives the data driver in the dot inversion polarity driving mode and 1+2H dot inversion polarity drivi...

Embodiment 2

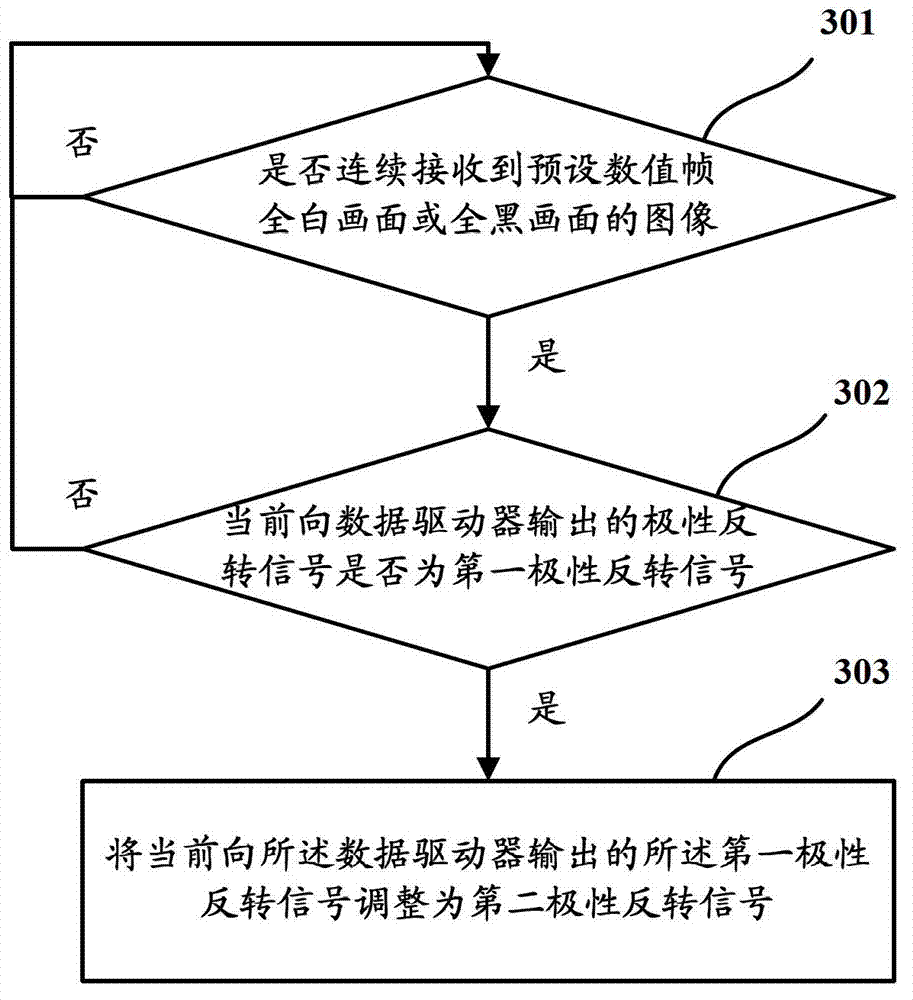

[0054] Such as image 3 Shown is a schematic flowchart of a polarity inversion signal conversion method according to Embodiment 2 of the present invention, and the polarity inversion signal conversion method includes the following steps:

[0055] Step 301, judging whether the image of the preset value frame full-white picture or full-black picture is continuously received, if yes, perform step 302, otherwise, continue to perform step 301;

[0056] In this embodiment, if images of the preset data frames are continuously received with an all-white picture or an all-black picture, it means that the display effect of the display is currently being tested.

[0057] The number of the preset values can be set according to needs, for example, it can be 2 or 3.

[0058] Step 302, judging whether the polarity inversion signal currently output to the data driver is the first polarity inversion signal, if yes, execute step 303, otherwise, execute step 301;

[0059] Step 303, adjusting...

Embodiment 3

[0063] Such as Figure 4 Shown is a schematic flowchart of a polarity inversion signal conversion method according to Embodiment 3 of the present invention, and the polarity inversion signal conversion method includes the following steps:

[0064] Step 401, judging whether the images of the preset value frames of all-white or all-black frames are continuously received, if yes, execute step 402, otherwise, continue to execute step 401;

[0065] Step 402, judging whether the polarity inversion signal currently output to the data driver is the first polarity inversion signal, if yes, execute step 403, otherwise, execute step 401;

[0066] Step 403, adjusting the first polarity inversion signal currently output to the data driver to a second polarity inversion signal, wherein the data driver is in the polarity corresponding to the second polarity inversion signal The power consumption generated by driving in a polarity driving mode is smaller than the power consumption generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com