Defect detecting method for utilizing graphic features to scan and manufacturing method of semiconductor chip

A defect detection and pattern feature technology, applied in the direction of semiconductor/solid state device testing/measurement, etc., can solve the problem of not being able to detect the chip and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

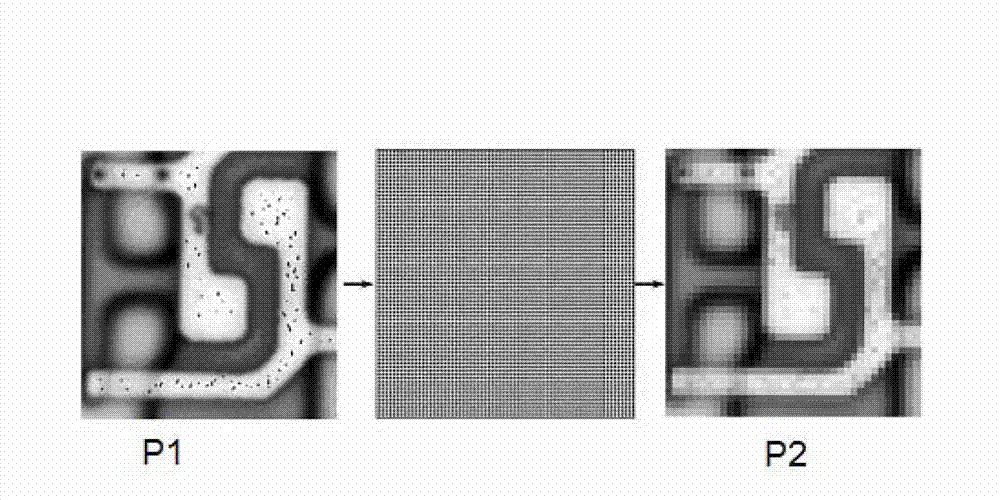

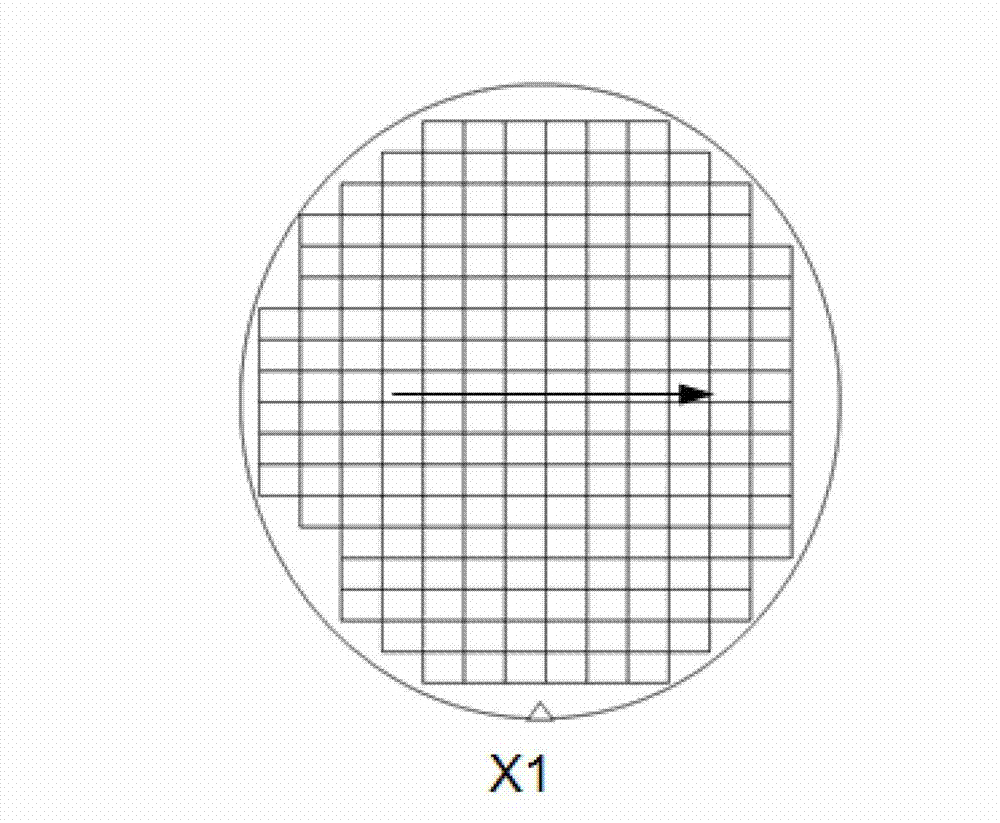

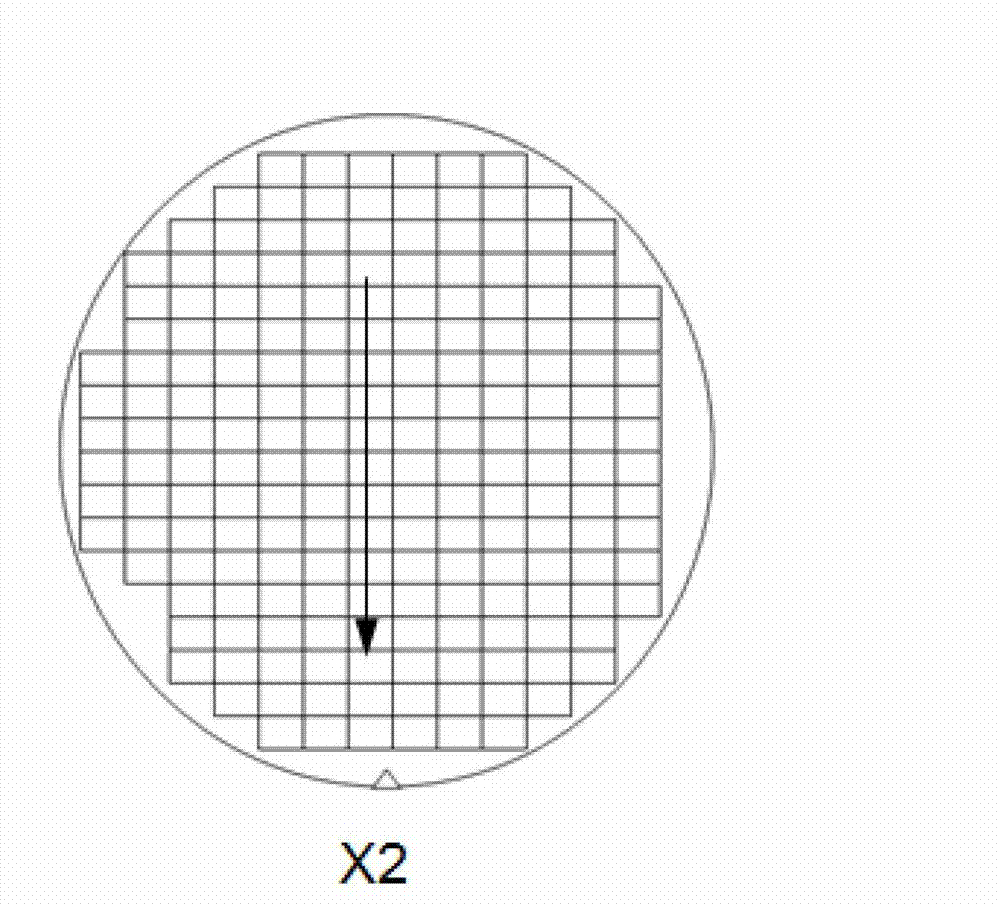

[0024] The inventors of the present invention have advantageously found that since regularly repeating semiconductor devices such as memories are all repeating units in physical structure, the smallest structure with periodic repetition can be obtained in the memory area of the chip during defect detection, Therefore, the position of the defect can be found by comparing the data in the horizontal or vertical direction by repeating the structure.

[0025] The technical principle of the present invention is to define repeating units cell1, cell2, cell3 and cell4 of semiconductor devices such as memory on the layout file of the chip through a terminal, such as Figure 5 Then import this file (repeating unit) into the defect detection program, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com