Tooling assembly, blanking tool therefor and associated method

A technology for processing tools and cutting materials, which can be used in household appliances, other household appliances, applications, etc., and can solve problems such as damage, abrasion, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

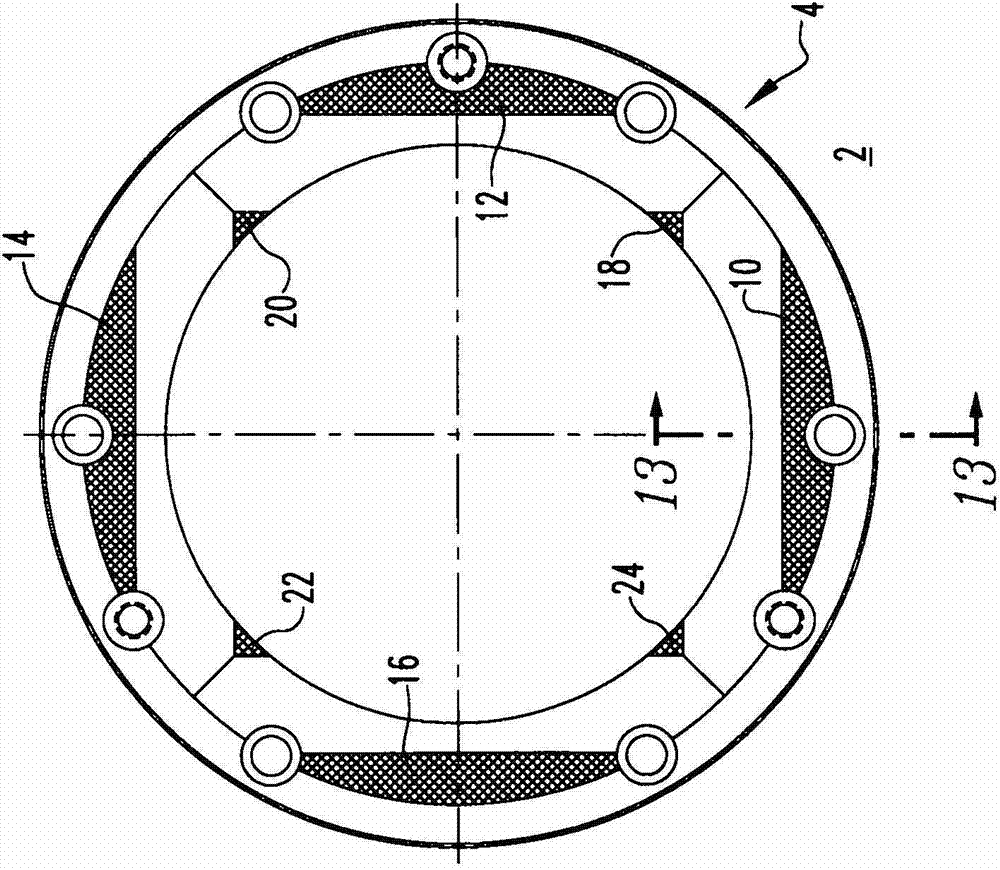

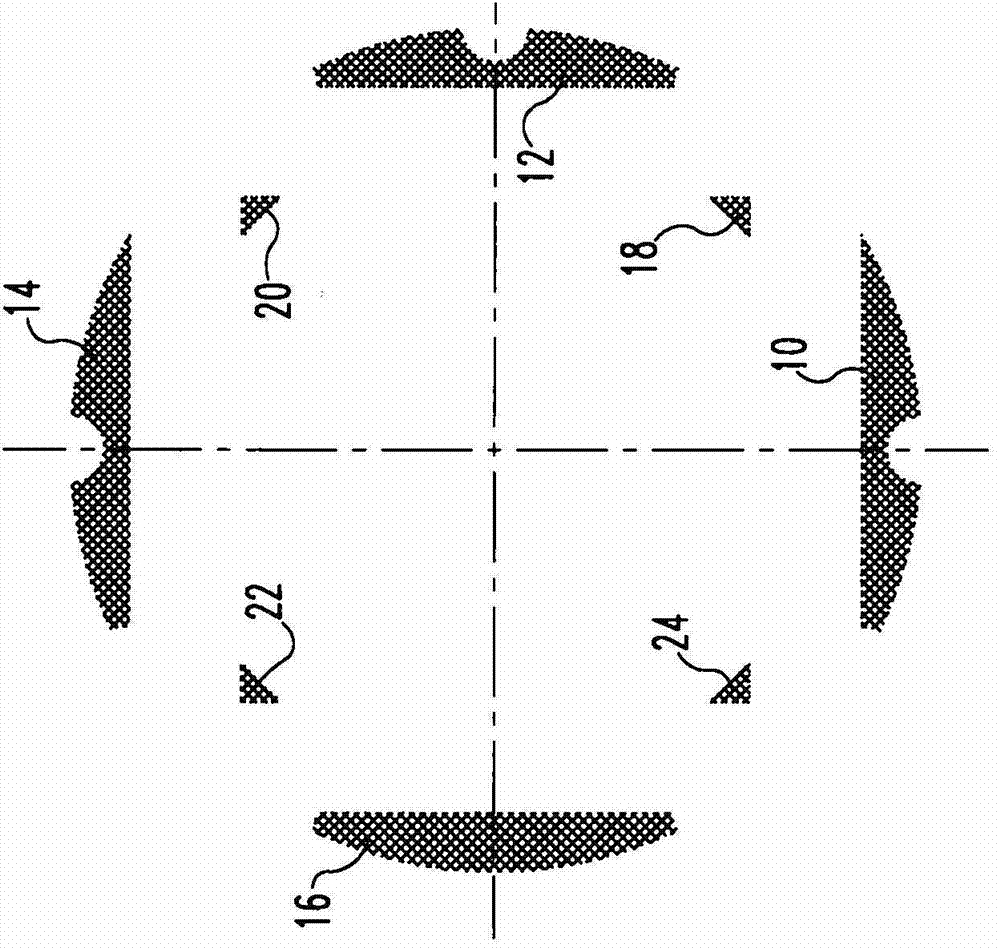

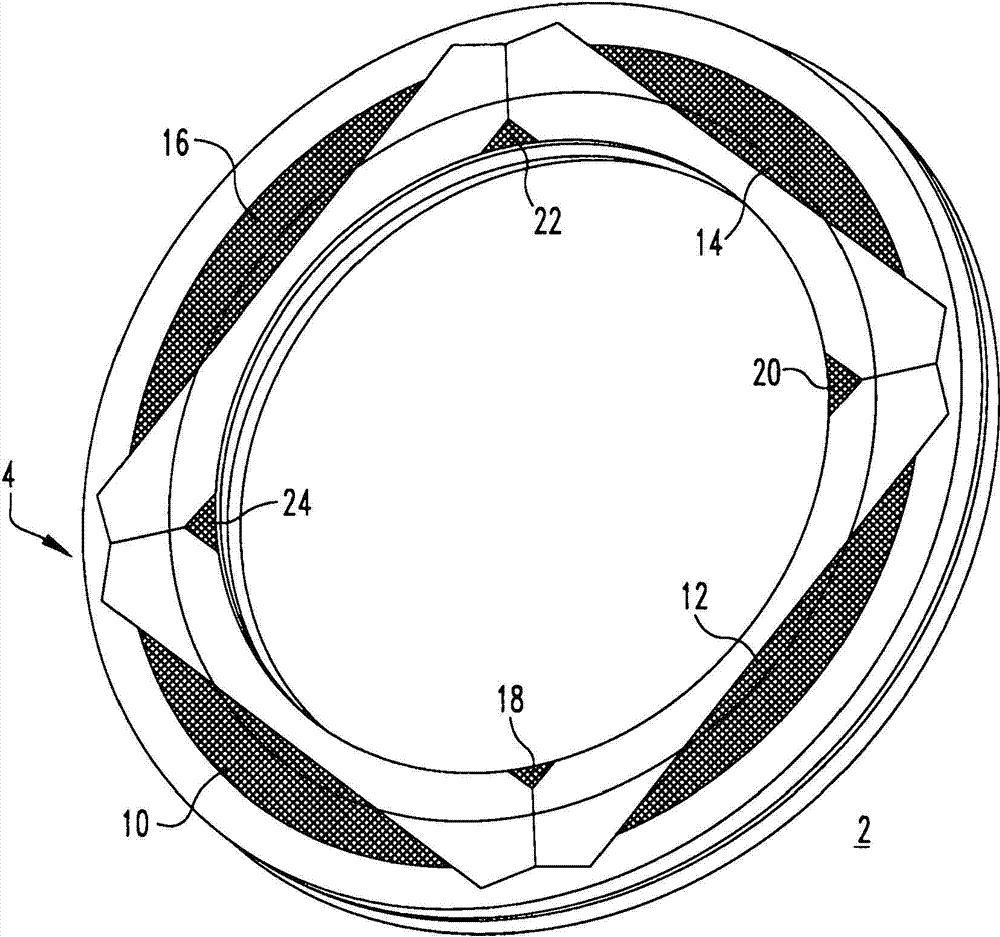

[0032] For purposes of illustration, embodiments of the invention will be described as applied to cutting (eg, shearing) blanks from a sheet of material, such as, but not limited to, sheet metal, and subsequently forming cups and containers from the blanks (eg without limitation beverage / beer cans; food cans), but obviously they can also be used to suitably cut (eg shear) any known blank or suitable material for a wide variety of different purposes and uses .

[0033] It is to be understood that certain elements shown in the drawings herein and described in the following description are merely exemplary embodiments of the invention, provided for purposes of illustration only, and are provided as non-limiting examples. Therefore, specific dimensions, orientations and other physical characteristics related to the embodiments disclosed herein are not to be considered as limiting the scope of the invention.

[0034]As used herein, directional terms such as left, right, front, bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com