Novel selvedge scissors for weaving machine

A technology of selvedge scissors and looms, which is applied in the direction of weaving auxiliary equipment, textiles, textiles and papermaking, etc. It can solve the problems of high mechanical failure rate, loss of processing enterprises and individuals, complex mechanical transmission, etc., and achieve low mechanical failure rate , simple structure and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

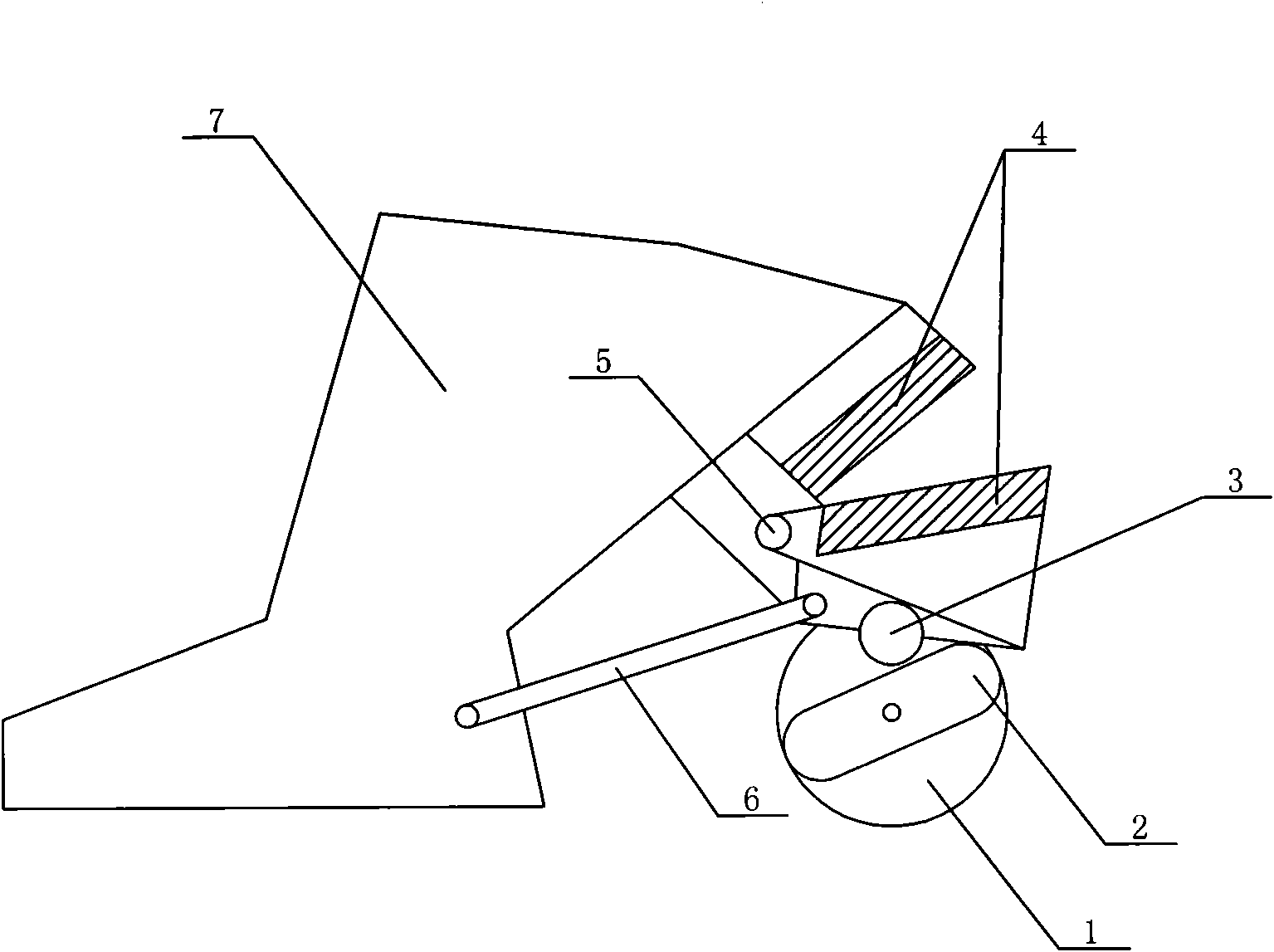

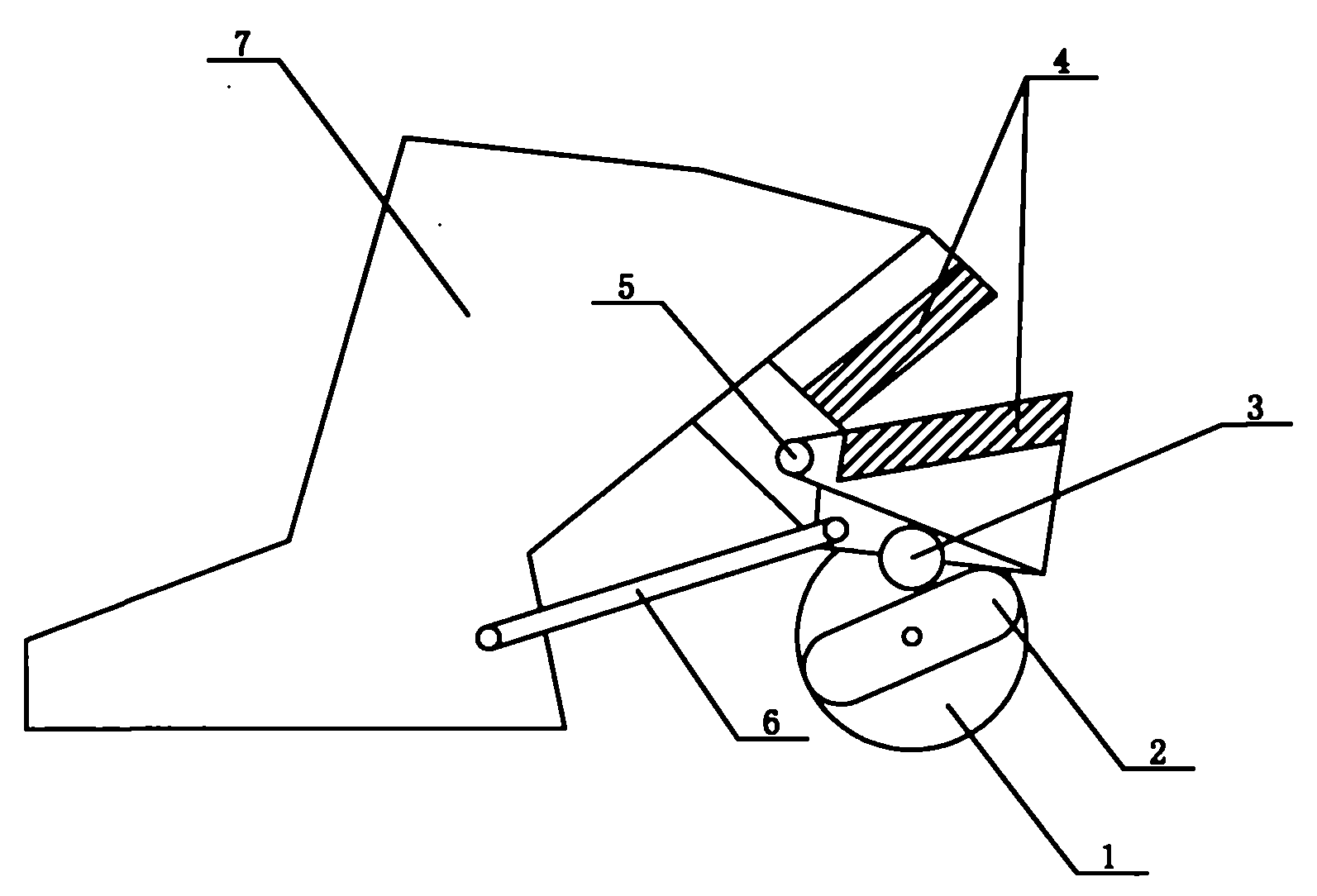

[0006] see figure 1 , the specific embodiment is to adopt the following technical scheme: it is made up of runner 1, plectrum 2, roller 3, blade 4, small shaft 5, connects stretching device 6 and knife rest 7. Wheel 1 is connected with plectrum 2, and roller 3 is installed in the lower end of blade 4, and blade 4 is connected by small shaft 5, and the two ends that connect stretching device 6 are connected with blade 4 and knife rest 7 respectively.

[0007] This specific embodiment has the advantages of simple structure, high transmission efficiency, and low mechanical failure rate. Since each component is connected as a whole, it can be effectively linked to form effective shearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com