A kind of sealing ring bonding pliers and using method

A sealing ring and bonding technology, which is applied in the field of sealing ring installation tools, can solve the problems of poor O-ring incision fit, poor bonding strength, bonding dislocation, etc., so as to facilitate the cutting and docking process, improve The effect of bonding quality and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

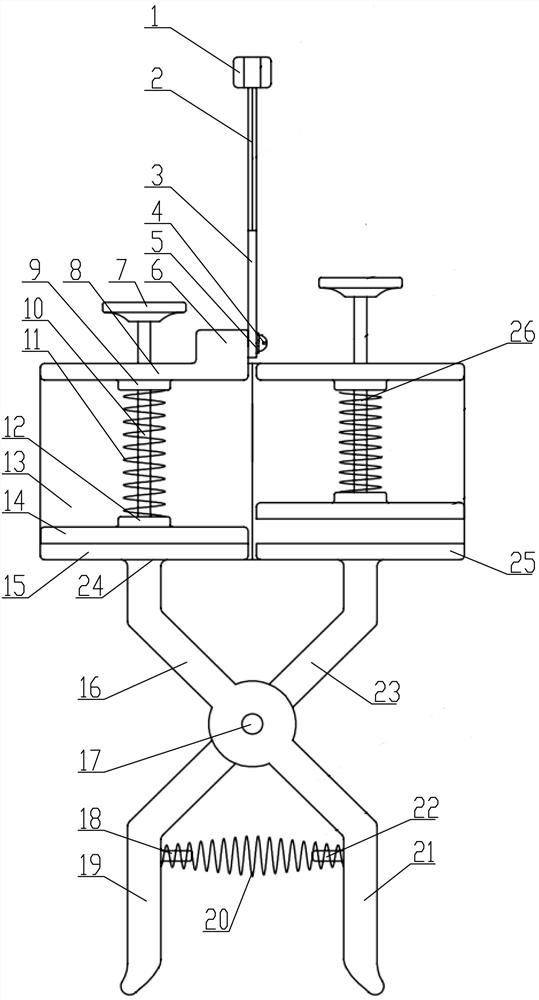

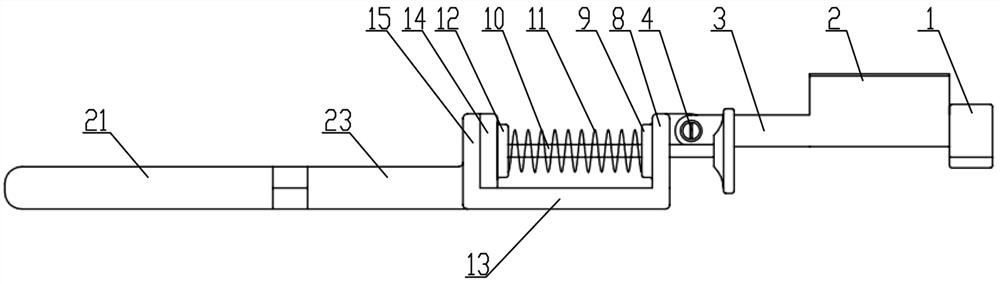

[0038] see Figure 1-2 , a sealing ring bonding pliers, which includes a first clamp arm 16 and a second clamp arm 23, the middle part of the second clamp arm 23 of the first clamp arm 16 is hingedly connected by a pin shaft 17, An automatic clamping mechanism for driving the two to realize the clamping action is provided between the tails of the first clamp arm 16 and the second clamp arm 23, and the end of the first clamp arm 16 is fixed with a first A clamp structure 24, the end of the second clamp arm 23 is fixed with a second clamp structure 25, and the first clamp structure 24 and the second clamp structure 25 are respectively equipped with the same structure for pairing A pressing mechanism 26 for pressing the end of the sealing strip, and a shearing device for cutting the sealing strip is installed on the first clamp structure 24 . By adopting the bonding pliers with the above structure, it is well suitable for precise, convenient and efficient bonding of O-rings with...

Embodiment 2

[0043] The method for bonding the sealing ring by using the sealing ring bonding pliers comprises the following steps:

[0044] Step 1: Check whether the closure between the first clamp structure 24 and the second clamp structure 25 is tight. If the closure is not tight, adjust the bonding pliers. Only after confirming that the clamp structure is tightly closed can the next step be performed;

[0045] Step 2: Select a sealing strip of appropriate length, mark A and mark B on both ends of the sealing strip according to the length of the sealing ring to be bonded and formed, then the length between marking A and marking B is the sealing strip length;

[0046] Step 3: Rotate and open the cutting blade 2 of the shearing device;

[0047] Step 4: Pull the handles 7 of the two sets of compression mechanisms 26, and release the pressure plate 14, and set the two sides of the end where the mark A of the sealing strip is located between the corresponding pressure plate 14 and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com