Vibration test apparatus

A technology of vibration testing and sliding devices, which is applied in vibration testing, measuring devices, and the use of repeated force/pulsation force to test the strength of materials, etc. It can solve problems such as wear and easy damage, and achieve the effect of thorough testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

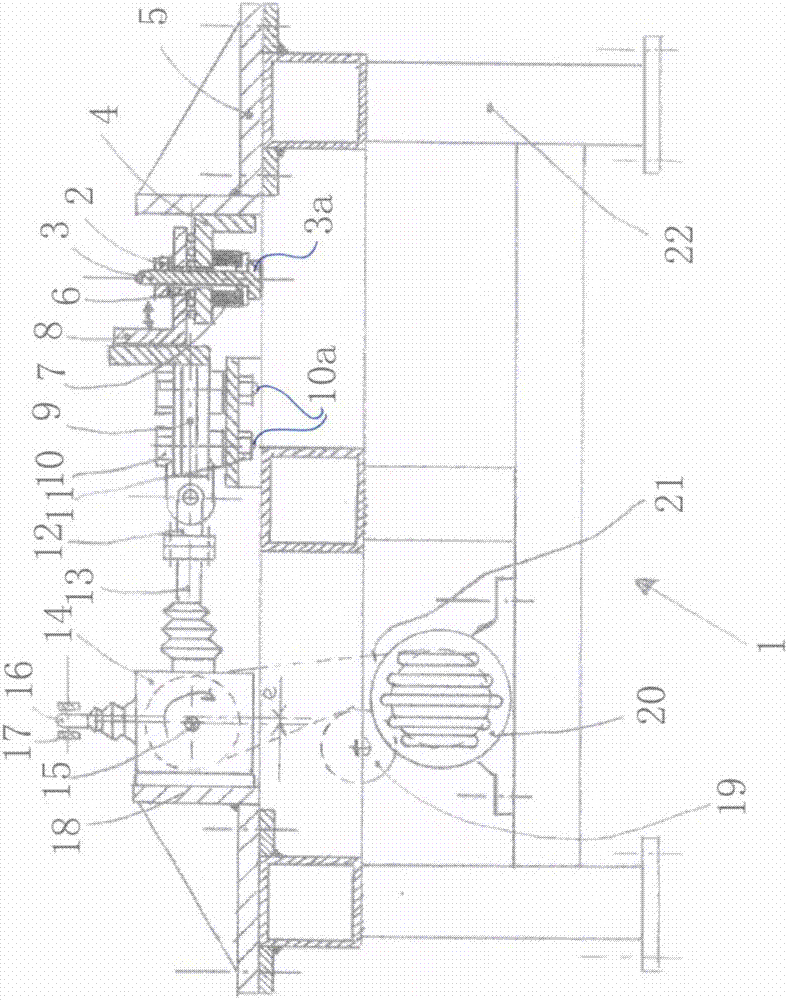

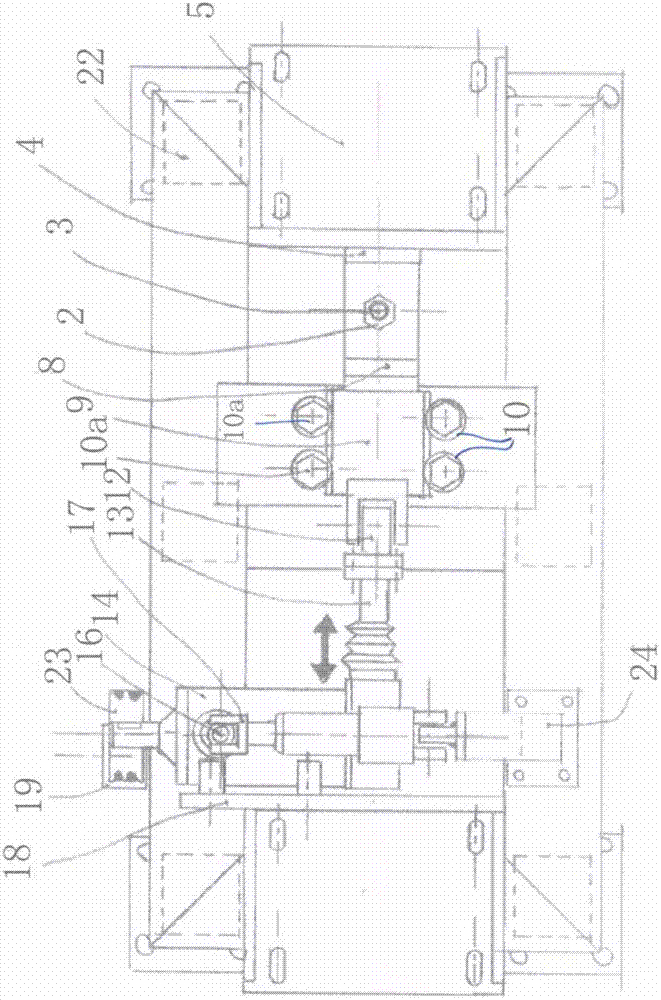

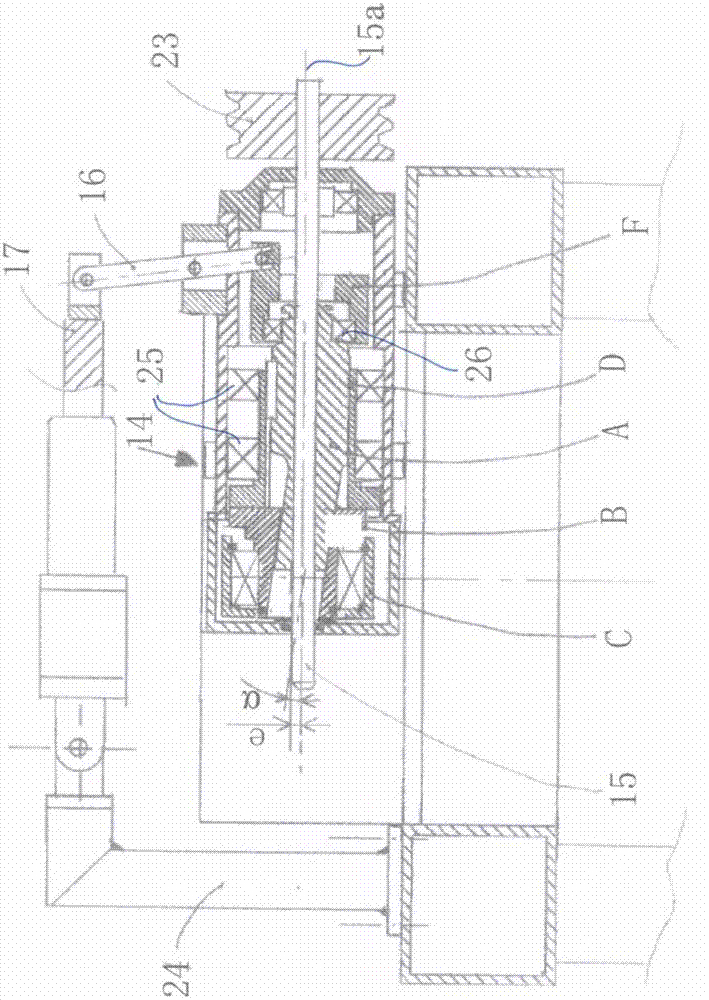

[0022] figure 1 A vibration testing device 1 is shown, wherein a nut 2 and a corresponding bolt 3 bolted together are installed between a lower flange 8 and an upper flange 8 . A ring-shaped load cell 7 is installed between the lower flange 4 and the bolt head 3a for converting the clamping force between the bolt head 3a and the lower flange 8 at any moment into an electrical signal. A plurality of cylindrical holes 6 are set between the lower flange 4 and the upper flange 8, so that the upper flange 8 can move laterally relative to the lower flange 4, and the lower flange 4 is fixed by a supporting bracket 5, and the supporting bracket 5 It is adjustably fastened to the frame body 22 through a plurality of oval holes.

[0023] The upper flange 8 is mounted on a laterally movable carriage 9 . The carriage 9 is guided by four positioned guide rollers 10 , each guide roller 10 is clamped to a frame 22 by a bolt 10 a and a nut 11 . The guide roller 10 is rotatably mounted on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com