Heat insulation/heat dissipation sheet and intra-device structure

A technology in a heat sink and a device is applied in the field of adiabatic heat sinks and the internal structure of the device, which can solve the problems of difficulty in ensuring the space of heat dissipation components, malfunction, burns, etc., and achieve the effect of preventing excessive heat reception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

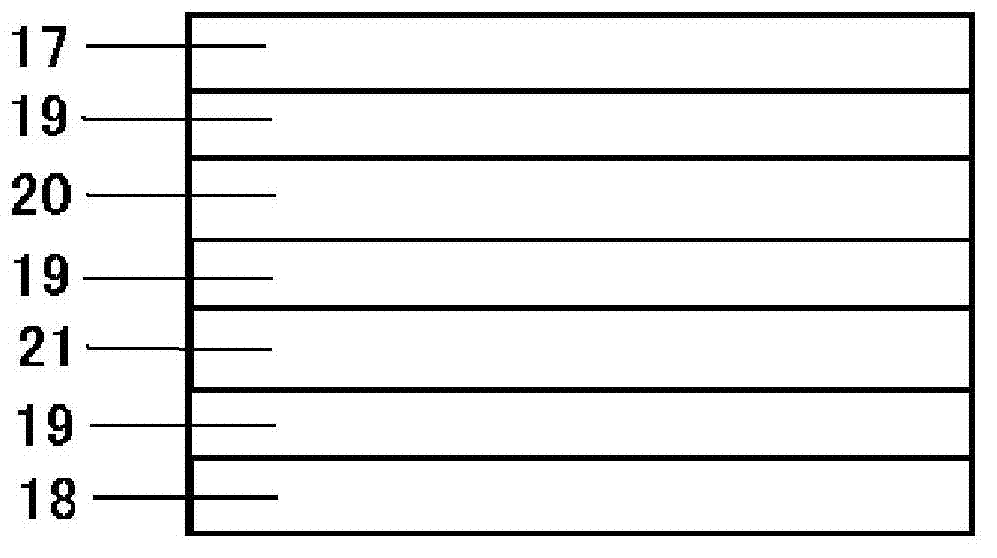

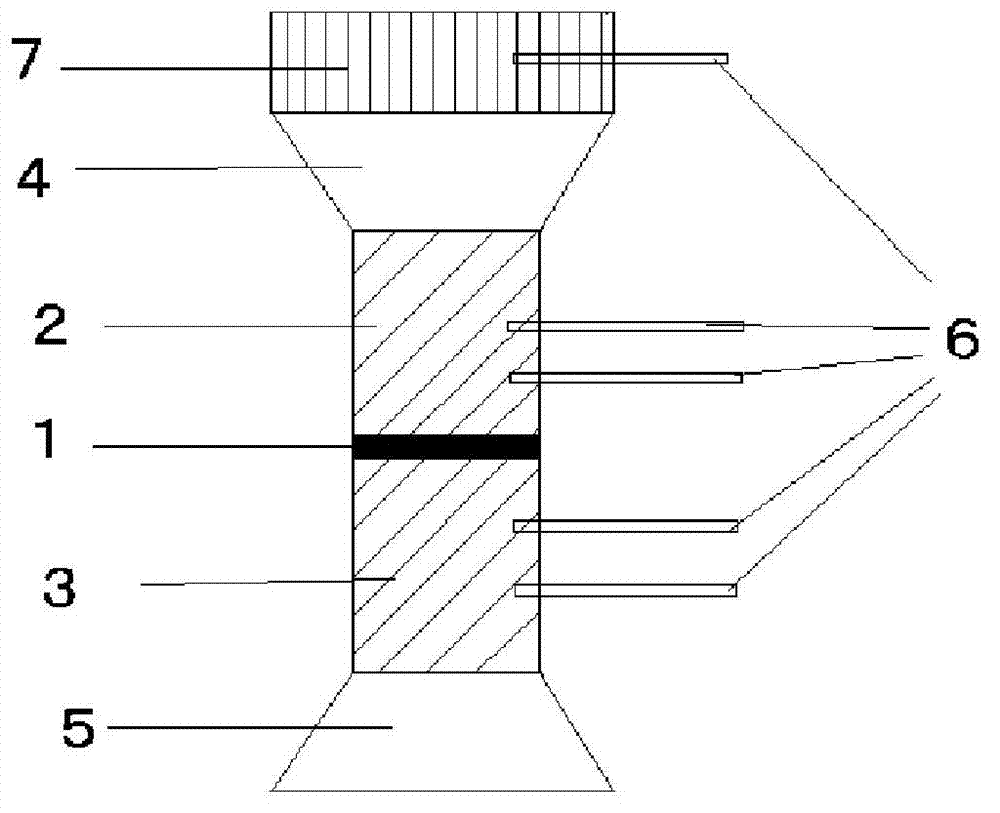

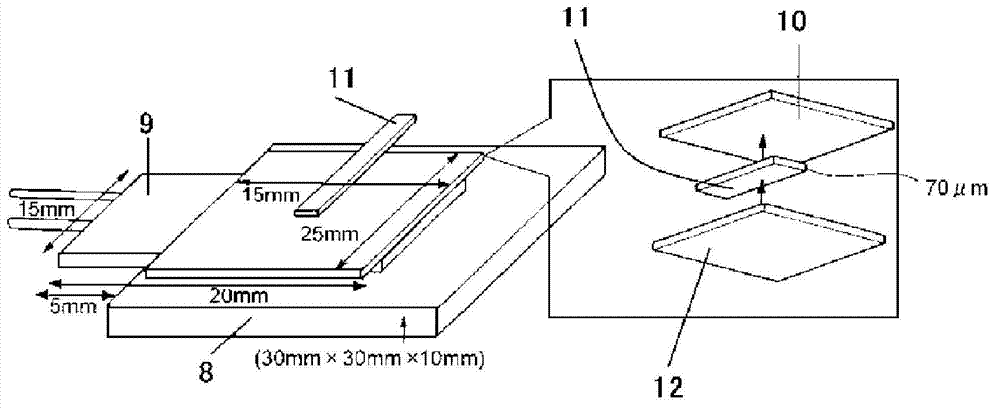

[0104] Use thickness 1.0mm, thermal resistance 20.26cm 2 ・K / W polyethylene foam sheet (manufactured by Sekisui Chemical Industry Co., Ltd., SOFTLON S (Japanese: ソフトロン S) #1001) is used as a heat insulating layer, and a synthetic rubber-like adhesive with a thickness of 0.10 mm is formed on both sides. Adhesive layer. Paste on one adhesive surface formed on the heat insulating layer as a heat conduction layer with a thickness of 0.040mm and a thermal resistance of 1.13cm 2 ・K / W aluminum foil (manufactured by Sumamigaru Aluminum Foil Co., Ltd., BESPA (Japanese: べスパー)). Thereafter, in order to perform heat dissipation and heat insulation evaluation, the other adhesive surface formed on the heat insulating layer was stuck to an acrylic plate having a size of 30 mm in length and 30 mm in width. At this time, a chip type thermocouple was installed between the sample and the acrylic plate so that the temperature of the test piece could be measured. After that, use a thickness of 0...

Embodiment 2

[0106] In addition to changing the heat conduction layer in Example 1 to a thickness of 0.025mm and a thermal resistance of 0.35cm 2 - Evaluation was performed in the same manner as in Example 1 except for a K / W graphite sheet (manufactured by Panasonic Denko Co., Ltd., EYGS182303).

Embodiment 3

[0108] In addition to changing the heat conduction layer in Example 1 to a thickness of 0.035mm and a thermal resistance of 1.46cm 2 - Except the copper foil of K / W, it evaluated similarly to Example 1 other than that.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com