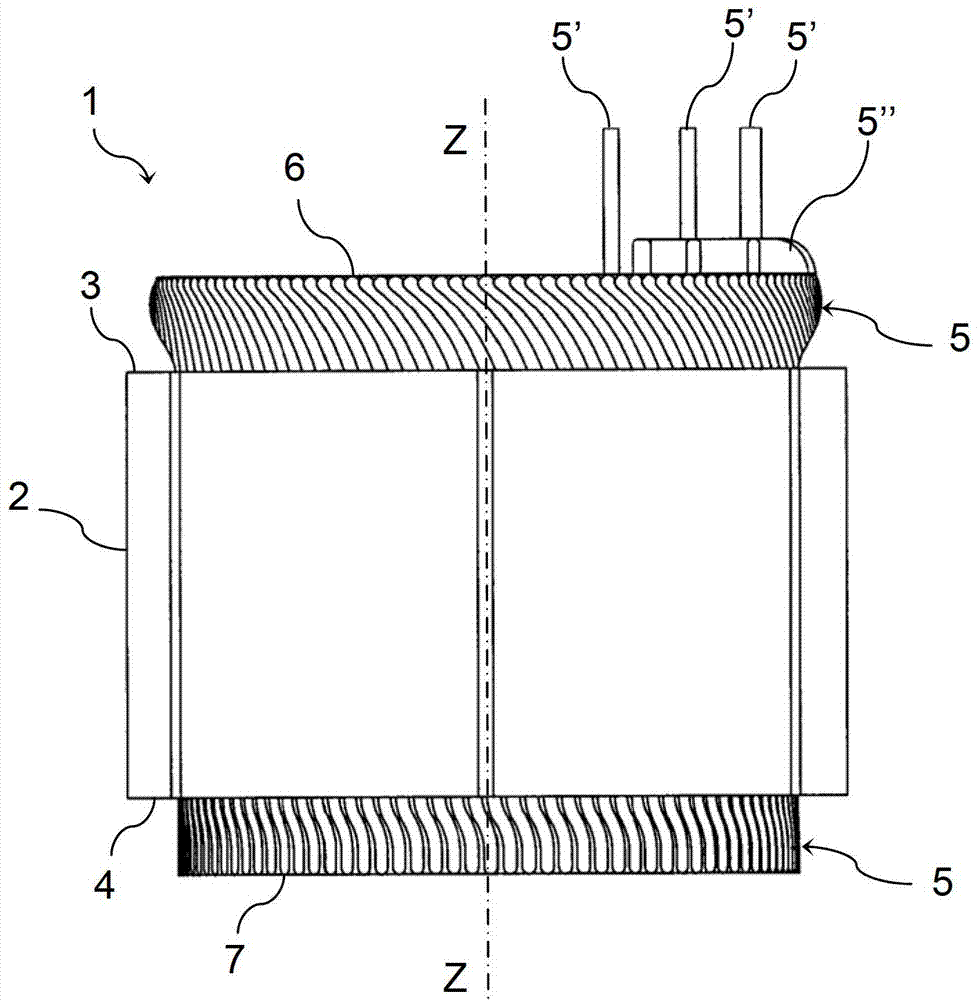

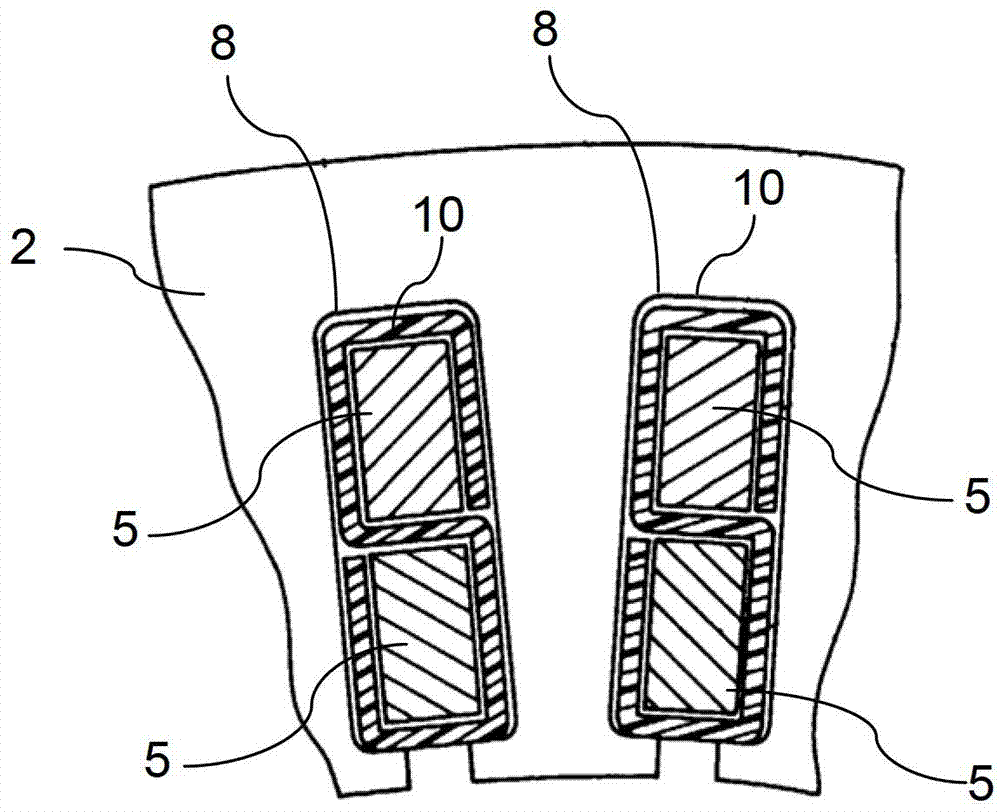

Apparatus and method for making pre-shaped insulating sheets intended to be inserted into stator or rotor slots

An insulating sheet and pre-forming technology, applied in the shape/style/structure of winding insulation, laying solid insulation, transportation and packaging, etc., can solve the problems of polluting gas or vapor release, toxicity, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

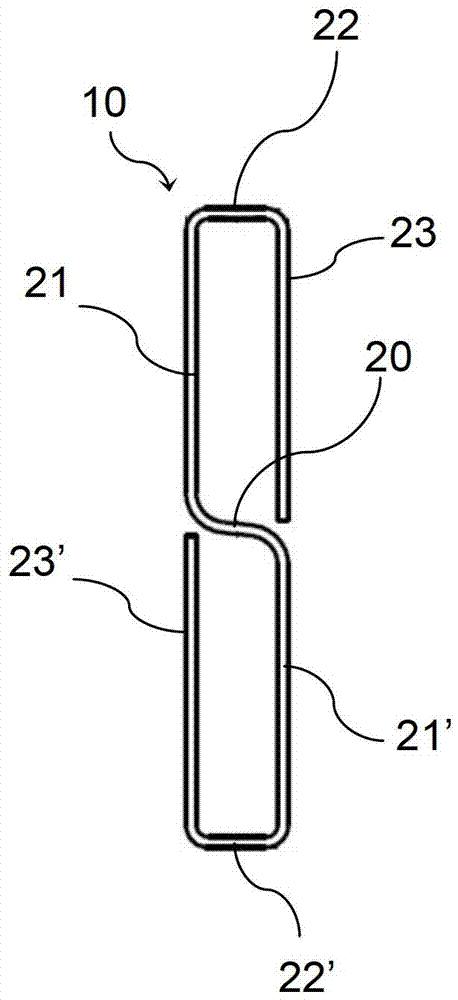

[0029] In the figures, the same reference numerals are used to designate the same or similar elements.

[0030] For purposes of this application, the term "flat" or "square" strip conductor is used to denote a strip conductor having four substantially flat faces, each joined to an adjacent face, usually by rounded corners.

[0031] Accordingly, the general use of the terms "flat" or "square" or equivalents to describe the cross-section of a strip conductor should not be considered as effectively excluding such strip conductors as having the ability to join substantially flat surfaces. fairly rounded corners. The term "flat conductor" should be understood as a conductor whose distance between two opposing faces is greater than the distance between the remaining two opposing faces. For the purposes of this application, the term "rectangular conductor" should be understood as a generalization of flat conductors and square conductors, given that a square conductor is a special ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com