Synthetic rice containing konjac high-quality dietary fiber

A technology of dietary fiber and artificial rice, which is applied in food preparation, food science, application, etc., can solve the problems of loss of various nutrients, single dietary structure of rice, unbalanced nutrition, etc. The effect of increasing toughness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

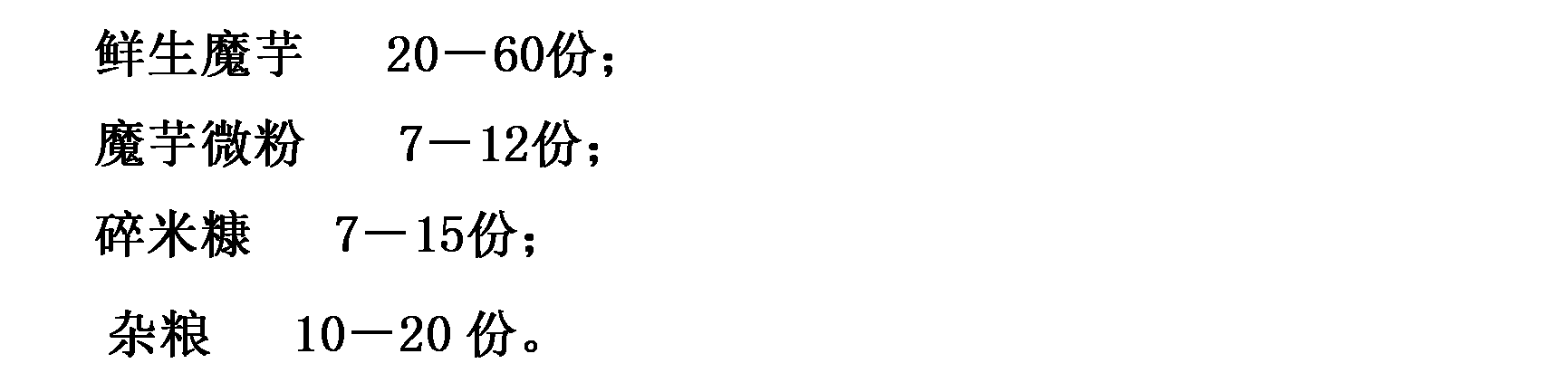

Method used

Image

Examples

Embodiment 1

[0025] Example 1. Get 10kg of fresh and raw konjac, 15kg of konjac powder, 5kg of broken rice bran and 30kg of miscellaneous grains, and make artificial rice rich in konjac high-quality dietary fiber according to the following steps:

[0026] A, fresh konjac is washed and peeled and crushed to obtain product A for subsequent use;

[0027] B, the konjac micropowder is ground into 300 orders to get the B product for subsequent use;

[0028] C. Roasting and ripening miscellaneous grains to obtain product C;

[0029] D, crush product C into powder to obtain product D for subsequent use;

[0030] G. Pulverize and steam the broken rice bran to obtain product E;

[0031] F. Mix product A, product B, product D and product E to obtain product F;

[0032] G. Put the F product into the extrusion granulator, cool down with tap water circulation, and control the temperature at 30°C to extrude and granulate to obtain the G product;

[0033] H. Place product G on a vibrating air bed and...

Embodiment 2

[0034] Example 2. Get 80kg fresh and raw konjac, 5kg konjac powder, 5kg broken rice bran and 5kg miscellaneous grains, make rich in konjac high-quality dietary fiber artificial rice according to the following steps:

[0035] A, fresh konjac is washed and peeled and crushed to obtain product A for subsequent use;

[0036] B, konjac micropowder is ground into 350 orders to get B product for subsequent use;

[0037] C. Roasting and ripening miscellaneous grains to obtain product C;

[0038] D, crush product C into powder to obtain product D for subsequent use;

[0039] G. Pulverize and steam the broken rice bran to obtain product E;

[0040] F. Mix product A, product B, product D and product E to obtain product F;

[0041] G. Put the F product into the extrusion granulator, cool down with tap water circulation, and control the temperature at 25°C to extrude and granulate to obtain the G product;

[0042] H. Place product G on a vibrating air bed and dry it with cold air to o...

Embodiment 3

[0043] Example 3. Get 20kg of fresh and raw konjac, 12kg of konjac powder, 15kg of broken rice bran and 10kg of miscellaneous grains, and make artificial rice rich in konjac high-quality dietary fiber according to the following steps:

[0044] A, fresh konjac is washed and peeled and crushed to obtain product A for subsequent use;

[0045] B, konjac micropowder is ground into 400 orders to get B product for subsequent use;

[0046] C. Roasting and ripening miscellaneous grains to obtain product C;

[0047] D, crush product C into powder to obtain product D for subsequent use;

[0048] G. Pulverize and steam the broken rice bran to obtain product E;

[0049] F. Mix product A, product B, product D and product E to obtain product F;

[0050] G. Put the F product into the extrusion granulator, cool down with tap water circulation, and control the temperature at 20°C to extrude and granulate to obtain the G product;

[0051] H. Place product G on a vibrating air bed and dry it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com