Food composition and preparation method thereof

A composition and food technology, applied in food preparation, food science, confectionery, etc., can solve the problems of not having good brittleness and chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

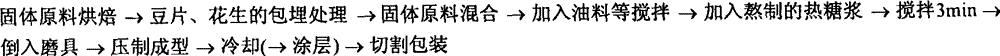

[0076] Process for the preparation of food compositions

[0077] The food composition provided by the invention can be prepared through a method comprising the following steps: mixing the processed defatted soybean flakes and syrup to obtain the food composition.

[0078] In a preferred example of the present invention, the processed defatted soybean flakes have been embedded with embedding materials.

[0079] In one embodiment of the present invention, the method for preparing the food composition of the present invention includes the steps of: the processed defatted soybean flakes, grains, and fruit embedded in the material embedding material Kernels, edible colloid, edible oil, humectant, phospholipid, nutritional enhancer and syrup are mixed to obtain a food composition.

[0080] In a preferred embodiment of the present invention, the method for preparing the food composition of the present invention comprises steps:

[0081] (a) Mix the processed defatted soybean flakes...

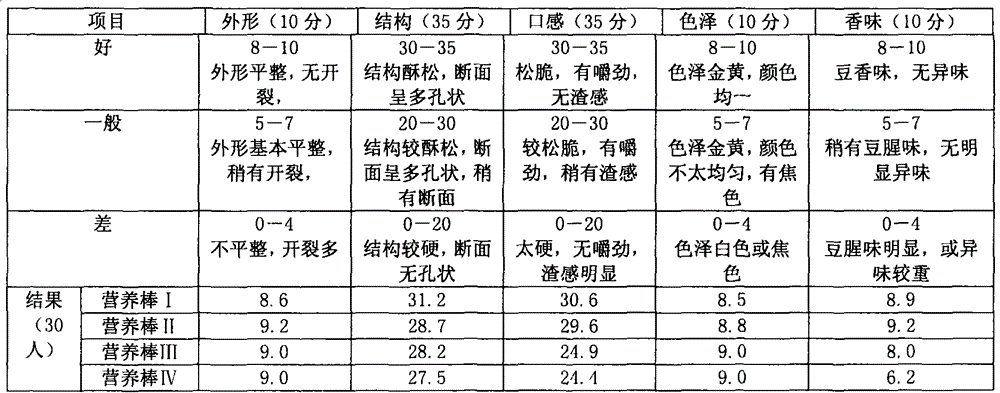

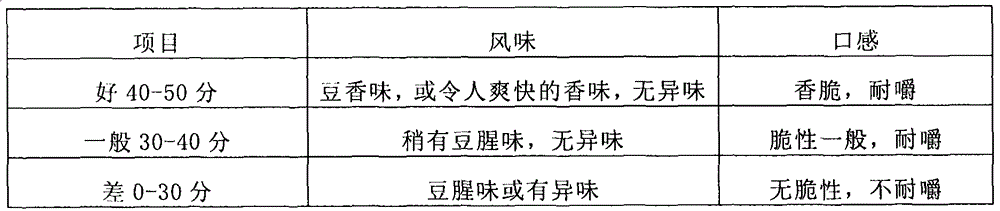

Embodiment 1

[0125] Nutrition Bar I

[0126] The defatted soybean flakes (purchased from Qinhuangdao Jinhai Food Industry Co., Ltd.) were sieved through a sieve with a pore size of 5 mm to remove small particle size powder and granules. Then bake at 160°C for 25 minutes until the bean chips are golden yellow.

[0127] The commercially available large grains of selected peanut kernels are baked together with the red coat at 160°C for 20 minutes to make them have obvious crispness and strong peanut flavor.

[0128] The material embedding material was prepared according to the following ratio: 11% of PG40 modified starch, 59% of maltitol, 2% of fructose, 0.5% of gum arabic, and 27.5% of water.

[0129] Use BGB-D series high-efficiency coating machine to spray and embed bean chips and peanut kernels. After embedding, dry the coating with a hot air dryer. The proportion (dry weight) of the material embedding material is 30% of the weight of bean chips and peanut kernels.

[0130] Use the em...

Embodiment 2

[0135] Nutrition Bar II

[0136] The pretreatment of soybean flakes and peanut kernels is also embedded with embodiment 1, and the product is made according to the following steps:

[0137] 1. Weigh the following materials: 120000g of soybean flakes, 45000g of oatmeal, 21000g of peanut kernels, 6000g of sesame seeds, 5100g of mineral / vitamin mixture, put them into a blender for mixing, and set aside;

[0138] 2. Weigh 6000g of gelatin (dissolved in a hot water bath after swelling with a small amount of cold water), 15000g of coconut oil, 5400g of phospholipids, 750g of vanillin essence, 12000g of glycerin, mix well, then add to the raw materials of step 1 and stir for about 3 minutes;

[0139] 3. Boil fructose syrup on low heat until the concentration is about 91 Brix, weigh 69000g, add it to the raw materials in step 2 for mixing, stir for about 3 minutes, quickly put it into a mold for pressing, and then cut it into 8×3 × 2cm rectangular blocks, packed after cooling, to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com