Making method of black bean/premna microphylla leaf pectin type Suanjiang tofu based on high-pressure homogenizing treatment

A high-pressure homogenization and pectin technology, which is applied in the direction of dairy products and food ingredients as antimicrobial preservation, food preservation, etc., can solve problems such as difficult to obtain satisfactory taste and flavor, and achieve improved texture, taste and flavor, uniform dispersion, Effect of antibacterial improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

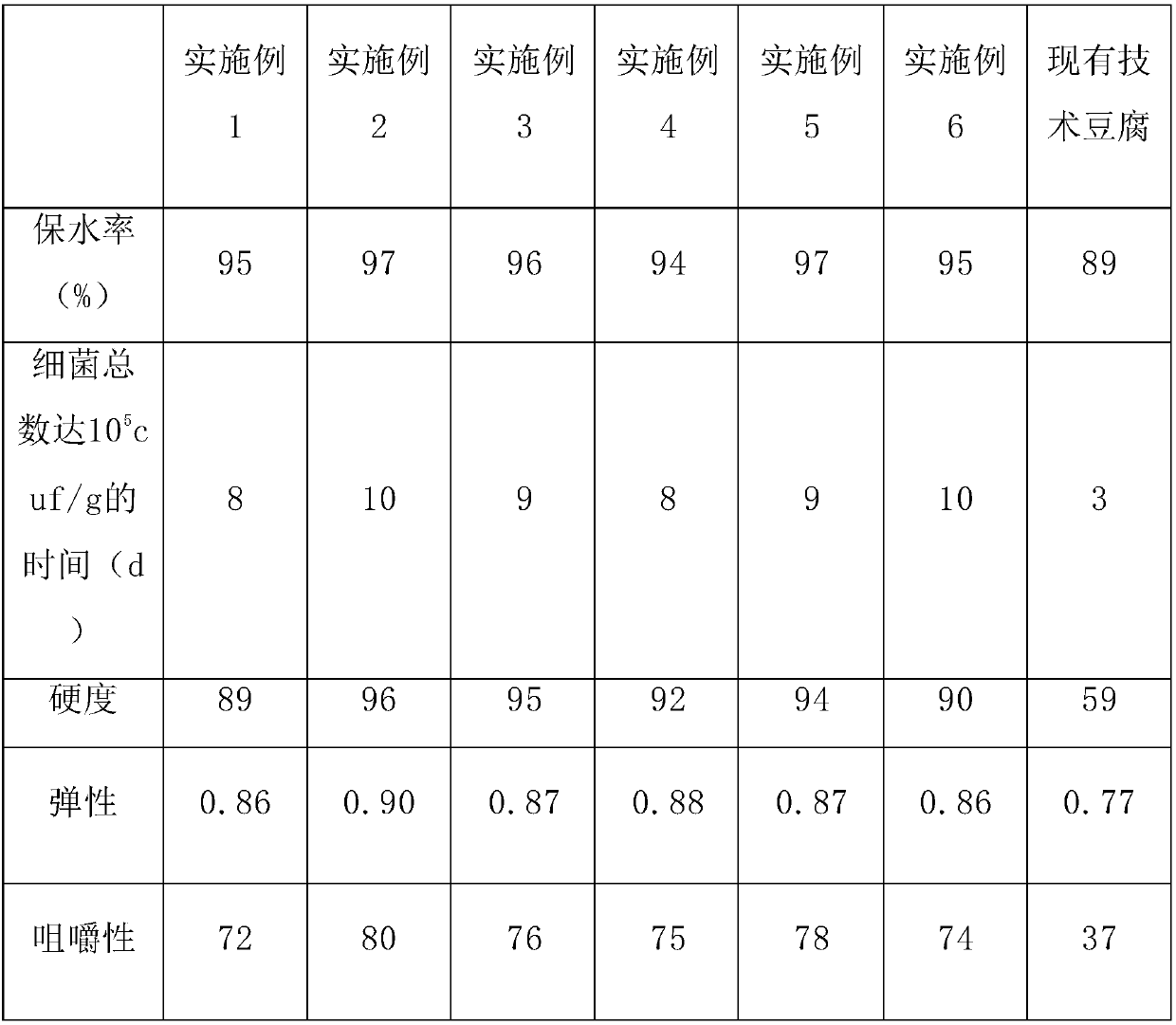

Examples

Embodiment 1

[0028] (1) Pick out the black beans with black skin and yellow kernels to remove impurities and cracked and deteriorated beans, add 3 times the volume of water to soak for 12 hours, take out the soaked black beans, and filter and boil the obtained soaked black beans to reduce bacteria before use.

[0029] (2) Pick out impurities and cracked and deteriorated bean grains from Northeast soybeans, add 3 times the volume of water to soak for 12 hours, take out soaked Northeast soybeans, and set aside.

[0030] (3) Add the black soybeans with black skin and yellow kernels processed in step (1) with a mass ratio of 2:1 and the Northeast soybeans processed in step (2) to the black soybean soaked water after processing in step (1), wherein black skin yellow The ratio of the total mass of kernel black soybeans and Northeast soybeans to the processed black soybean soaking water is 1g:3mL, and they are ground in an electric refiner to obtain raw soybean milk, wherein the raw soybean milk h...

Embodiment 2

[0035] (1) Pick out the black beans with black skin and yellow kernels to remove impurities and cracked and deteriorated beans, add 5 times the volume of water to soak for 24 hours, take out the soaked black beans, and filter and boil the obtained soaked black beans to reduce bacteria before use.

[0036](2) Pick out impurities and cracked and deteriorated beans from Northeast soybeans, add 5 times the volume of water to soak for 24 hours, take out soaked Northeast soybeans, and set aside.

[0037] (3) Add the black soybeans with black skin and yellow kernels processed in step (1) with a mass ratio of 2:1 and the Northeast soybeans processed in step (2) to the black soybean soaked water after processing in step (1), wherein black skin yellow The ratio of the total mass of kernel black soybeans and Northeast soybeans to the processed black soybean soaking water is 1g:6mL, and they are ground in an electric refiner to obtain raw soybean milk, wherein the raw soybean milk has a Ba...

Embodiment 3

[0042] (1) Pick out the black beans with black skin and yellow kernels to remove impurities and cracked and deteriorated beans, add 4 times the volume of water to soak for 18 hours, take out the soaked black beans, and filter and boil the obtained soaked black beans to reduce bacteria before use.

[0043] (2) Pick out impurities and cracked and deteriorated bean grains from Northeast soybeans, add 4 times the volume of water to soak for 18 hours, take out soaked Northeast soybeans, and set aside.

[0044] (3) Add the black soybeans with black skin and yellow kernels processed in step (1) with a mass ratio of 2:1 and the Northeast soybeans processed in step (2) to the black soybean soaked water after processing in step (1), wherein black skin yellow The material ratio of the total mass of kernel black soybeans and Northeast soybeans to the treated black soybean soaking water is 1g:4mL, and grind in an electric refiner to obtain raw soybean milk, wherein the raw soybean milk has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com