Carbon fiber enhanced composite material panel and preparation method thereof

A reinforced composite material and carbon fiber technology, applied in chemical instruments and methods, lamination devices, lamination, etc., to achieve the effect of natural texture, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

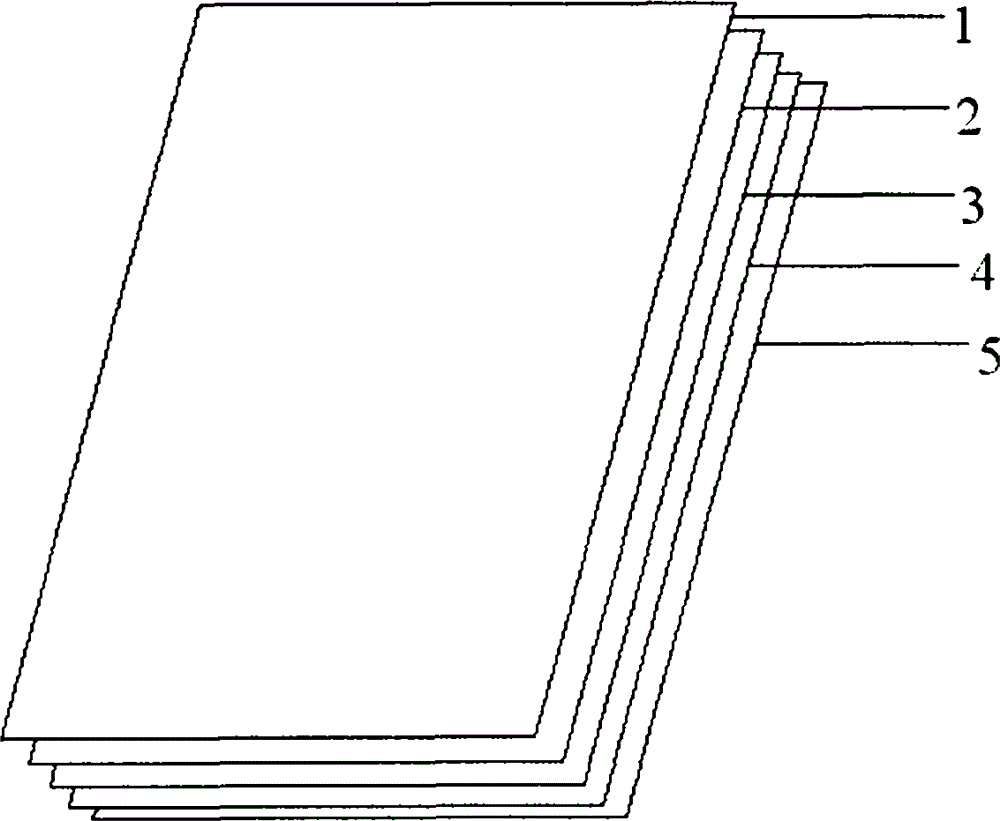

[0017] figure 1 It is a schematic diagram of the structure of a carbon fiber reinforced composite material board, including at least five layers with a thickness of 0.8mm-20mm. The first layer 1 is natural sliced veneer, the second layer 2 is a non-woven fabric layer, and the third layer 3 is used The first carbon fiber, the fourth layer 4 use the second carbon fiber, and the fifth layer 5 uses the third carbon fiber or natural sliced veneer.

[0018] The first layer 1 uses natural sliced veneer with a thickness of 0.2mm and a width of 60mm. The natural sliced veneer is black walnut, ebony, red oak, white oak or teak; the non-woven layer adopts 5g / m 2 White non-woven fabric with a thickness of 0.1mm; the first carbon fiber is a carbon fiber unidirectional prepreg, and the fiber weight is 145g / m 2 , Resin content 45%, laying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com