Fan diffuser structure for dust collector

A diffuser, vacuum cleaner technology, applied in vacuum cleaners, machines/engines, components of pumping devices for elastic fluids, etc., can solve the problems of low flow efficiency, loss of flow energy, high air flow rate, etc., to achieve uniform airflow speed The effect of distribution, increasing space and floor area, reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

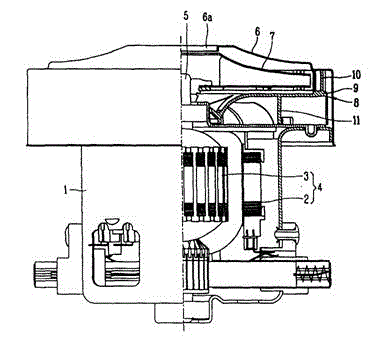

[0035] The fan diffuser structure of the present invention is arranged in such as figure 1 In the shown vacuum cleaner fan motor unit, the fan motor unit includes a motor casing 1 with an opening formed at the upper end, and a motor 4 composed of a stator 2 and a rotor 3 is arranged inside the motor casing 1; it is inserted into the center of the rotor 3 up and down part, and rotate together with the rotor 3, and provide the rotating shaft 5 for the rotor 3 to rotate power.

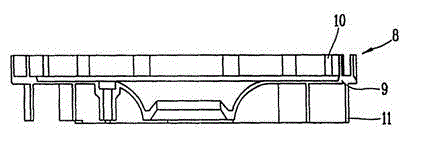

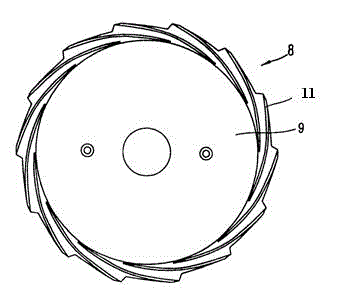

[0036] A fan housing 6 having a suction port 6a formed in the center is coupled to the upper opening portion of the motor housing 1 . The inside of the fan casing 6 is provided with a fan 7 that is coupled to the rotating shaft 5 and sucks in air through the suction port 6a, and there is a diffuser th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com