Internal and external cavity combined type trapped vortex combustion chamber

A combustion chamber and concave cavity technology is applied in the field of trapped vortex combustion chambers with combined configuration of inner and outer concave cavities, which can solve the problems of low combustion efficiency and pollutant emission efficiency, limited combustion reaction area and area, unfavorable grading and zonal combustion, etc. Improve combustion efficiency, increase low-speed mixing space and combustion area, and inhibit nitrogen oxides and other pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. protection scope of the invention.

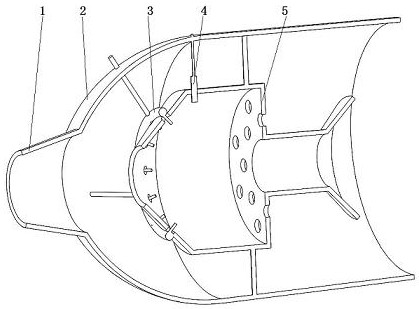

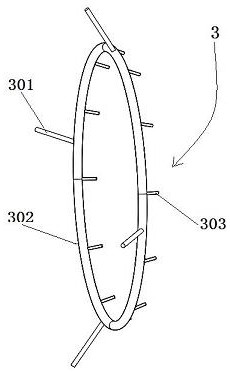

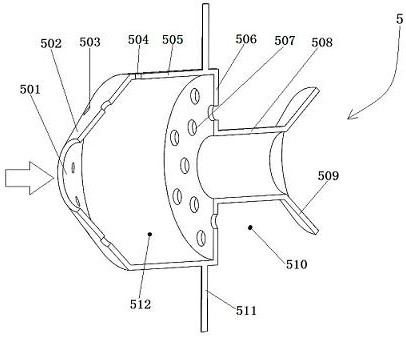

[0022] A trapped vortex combustor with a combination of inner and outer concave cavities, such as Figure 1 to Figure 3 As shown, the trapped vortex combustion chamber includes a diffuser 1, a combustion chamber housing 2, an oil delivery pipe 3, an igniter 4, and a flame tube 5 with a combination of inner and outer concave cavities; the combustion chamber housing 2 and the diffuser 1 connect. The oil delivery pipe 3 includes a main oil pipe 301, an annular oil pipe 302 and a thin oil pipe 303. Both the main oil pipe 301 and the thin oil pipe 303 are bendable metal pipes, which are convenient for actual assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com