Covering part forming mold and design and use method thereof

A technology for forming molds and covering parts, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex forming deformation process, increased mold cost, uneven stress, etc., to reduce design cycle, low maintenance cost, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

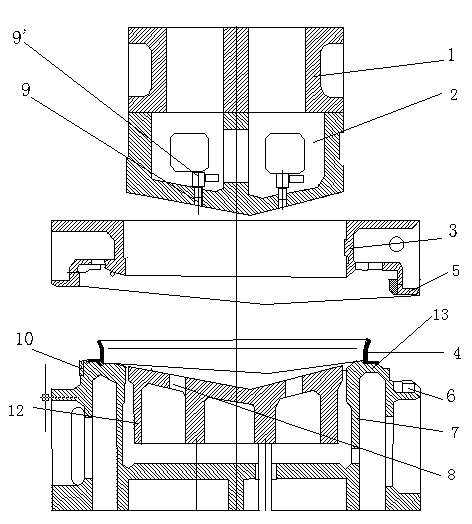

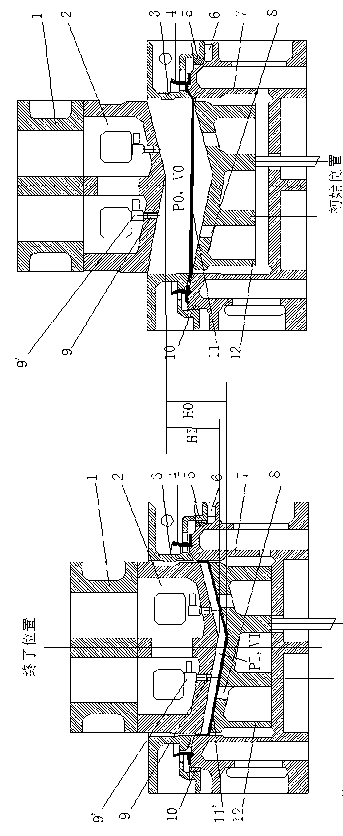

[0036] Embodiment 1 The structure and parameter design of the cover forming mold of the present invention

[0037] The covering part of the present invention may be large, medium and small covering parts used on automobiles, tractors or airplanes and other similar vehicle bodies. Such as figure 1 As shown, the cover forming mold includes a punch base 1, a punch 2 installed on the punch base, a binder ring 3, and a die 7 with a stopper 4 at the mouth 13. A top piece plate 12 and a die vent hole 8 are provided, the punch 2 is provided with a punch vent 9, and the punch vent 9 is connected to the atmosphere with a one-way pressure control valve 9'; There is a complete sealing fit between the material ring 3 and the punch 2, and there is no loosening phenomenon during the pressing process; a back-to-block guide plate 10 and a stroke control block 6 are provided outside the die 7 . The lower end of the binder ring 3 is provided with a binder ring foot 5 for cooperating with the ...

Embodiment 2

[0054] Example 2 Method of forming a cover using the mold of the present invention

[0055] Use the air pressure forming method of mold forming covering of the present invention, comprise following process:

[0056] (1) Place the blank on the die mouth and position it;

[0057] (2) The double-action press first presses the binder ring against the blank;

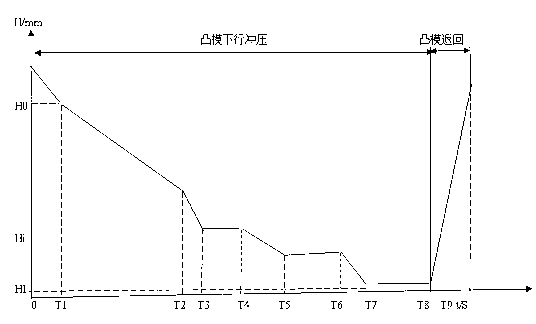

[0058] (3) The press continues to move the punch downward for stamping. Since the one-way pressure control valve on the punch is in a closed state, a closed space is formed between the punch, the blank and the binder ring, and the air in this space moves along with the punch. The downward direction is compressed, and the air pressure generated causes the blank to gradually deform and fit on the die, and finally completely press it on the surface of the die to form a cover;

[0059] (5) demoulding. During the demoulding process, when the air pressure in the enclosed space is less than 0.9-1.1 standard atmospheric pressure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com