Embroidery thread spool

An embroidery thread and spool technology, which is applied in the field of accessories for the textile industry, can solve the problems of falling off, the thread coming out, and the winding can no longer be used, and achieves the effect of increasing friction, not easy to fall off, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

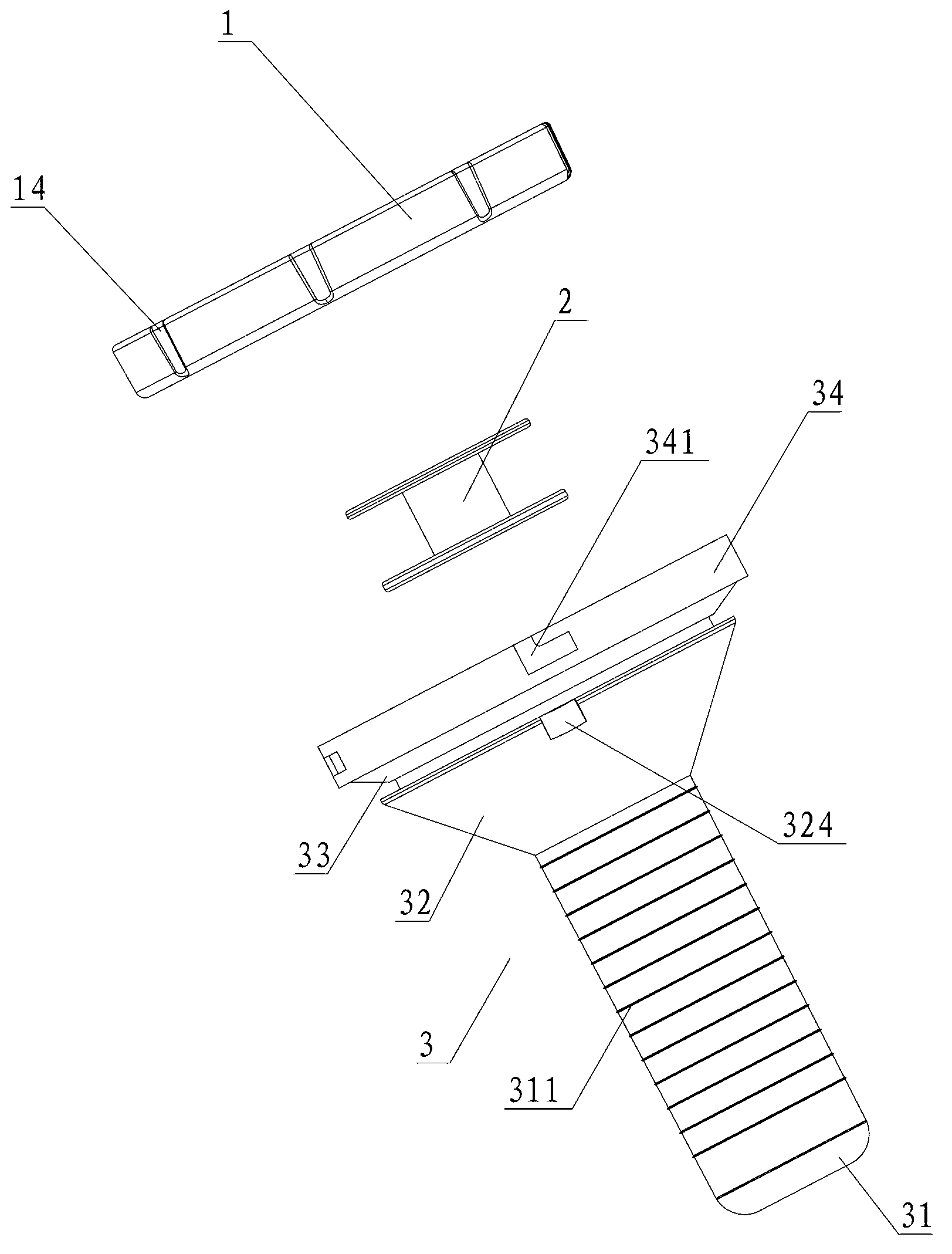

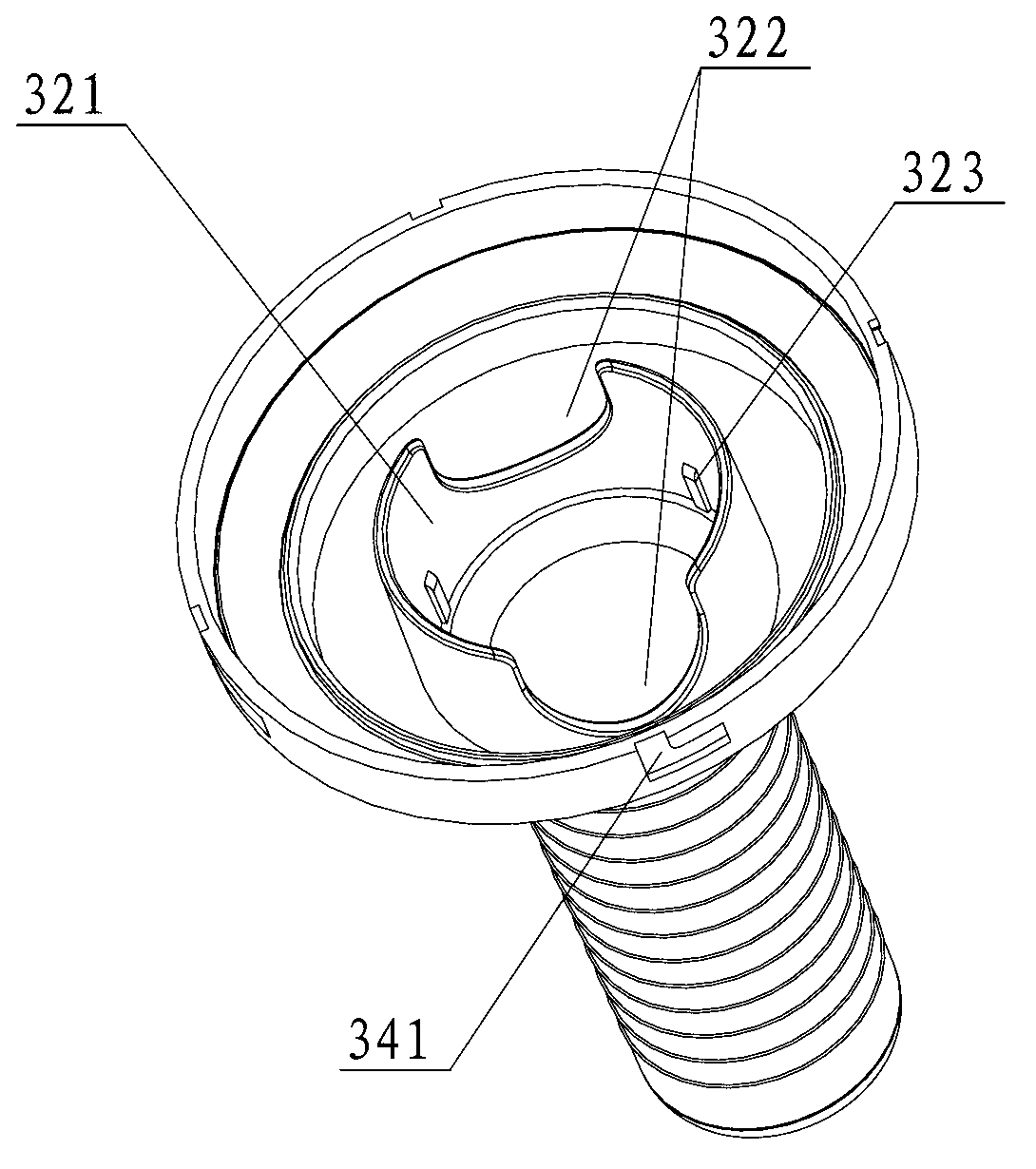

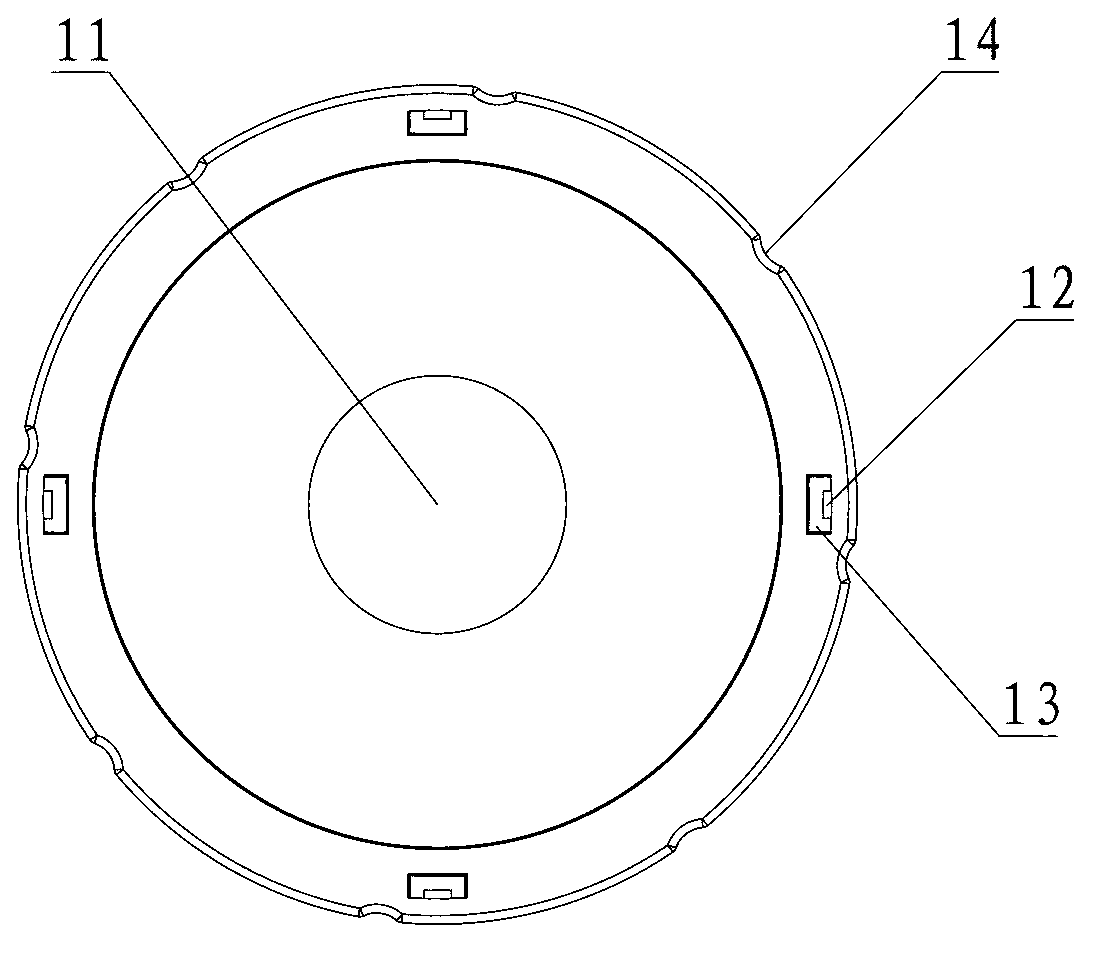

[0026] see Figure 1-4 , the present embodiment is an embroidery bobbin, which includes an end cap 1 and a hollow 35 bobbin body 3 . Correspondingly, an opening 11 is provided on the end cover 1 corresponding to the hollow 35 of the bobbin body 3 . The bobbin main body 3 at least includes a winding segment 31, a storage segment 32 and a connecting segment 34 which are connected in sequence. A retainer 321 extends inside the storage segment 32, and the retainer 321 surrounds and forms an accommodation for placing the bobbin grain 2. cavity. Preferably, the retainer 321 is provided with a slot 322, and the best slot 322 includes two symmetrical ones arranged on the retainer 321, so as to facilitate the insertion and removal of the bobbin g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com