Braking method of traction machine and low-noise brake

A low-noise, brake technology, applied in the hoisting device and other directions, can solve the problems of large impact sound, loud noise, and large impact force, and achieve the effects of improving electromagnetic suction, reducing friction loss, and increasing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

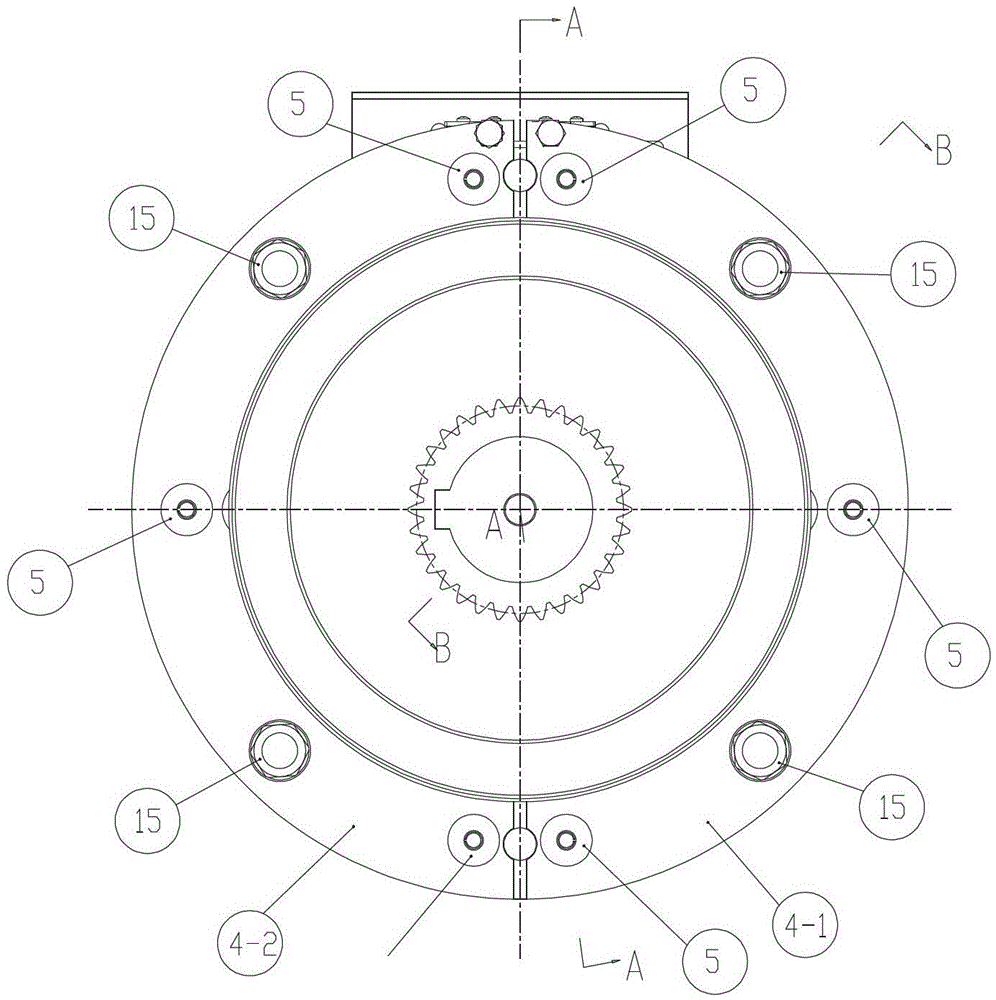

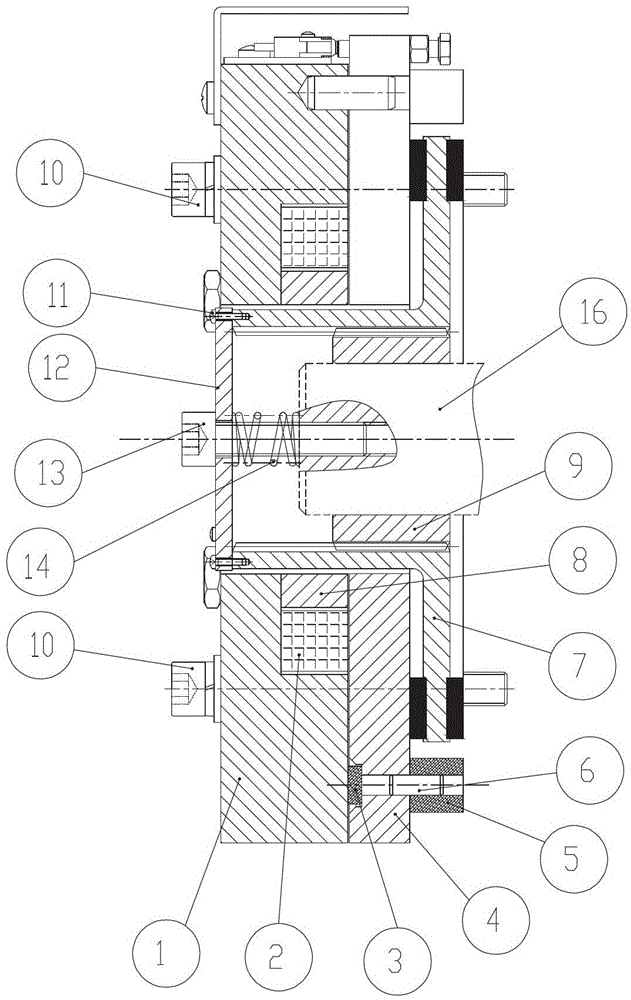

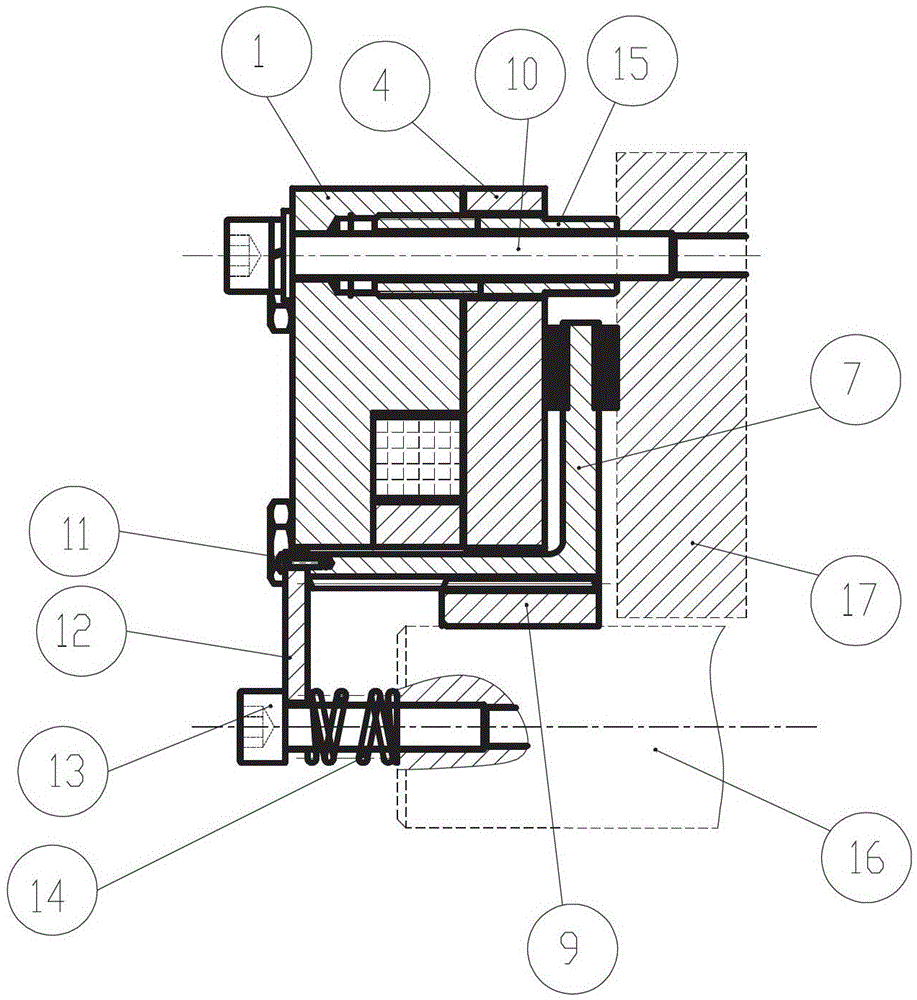

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0021] Example. A braking method for a traction machine. The armature is activated by attracting the armature with an iron core. When braking is required, the armature presses the brake disc fixed to the installation shaft of the traction machine against the installation end cover. Since the armature and the installation end cover cannot rotate relative to each other, they can only be axially displaced, so that the traction machine can be braked, and when the armature is pressed against the brake disc, an elastic shock-absorbing column is arranged on the back of the armature to avoid instantaneous pressure of the armature. Impact noise against the brake disc. The shock-absorbing column is fixed on the armature or the end cover. The armature is divided into left and right pieces, and the two pieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com