Label film paint and manufacturing method thereof

A production method and coating technology, applied in the direction of coating, can solve the problems of poor bonding of synthetic paper coating, easy tearing off, poor ink printing effect, etc. The effect of flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

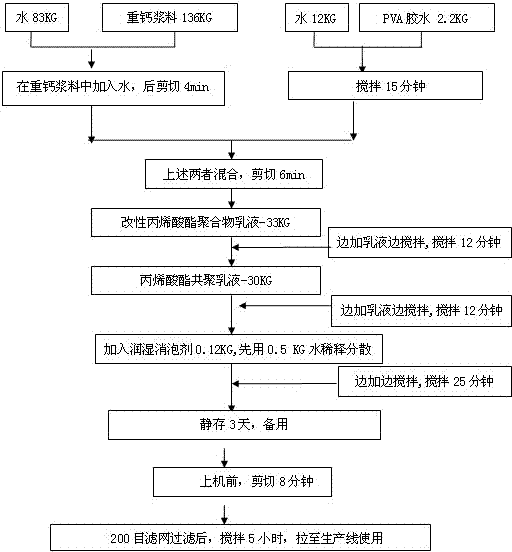

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0029] Preferably, the label film coating components and content are as follows:

[0030] Water: 95.5kg

[0031] Heavy calcium slurry: 136kg

[0032] PVA glue: 2.2kg

[0033] Modified acrylate polymer emulsion: 33kg

[0034] Acrylate copolymer emulsion: 30kg

[0035] Wetting defoamer: 0.12kg

[0036] The main functional group of the modified acrylate polymer emulsion is carboxyl, and the polymerization monomers are methacrylic acid and isooctyl acrylate, as well as methyl methacrylate and styrene;

[0037] The main functional group of the acrylate copolymer emulsion is carboxyl, and the polymerization monomers are methacrylic acid, isooctyl acrylate, methyl methacrylate, styrene, and butyl acrylate.

[0038] Preferably, the PVA glue is made by the following method: put 10% of PVA particles into water at 25°C by weight percentage, stir, then hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com