Device and method for continuously preparing polyisophthaloyl metaphenylene diamine spinning solution

A technology of poly-m-phenylene isophthalamide spinning and poly-m-phenylene isophthalamide is applied in the directions of single-component polyamide rayon, spinning solution preparation, etc., and can solve the problem of reducing the system Apparent viscosity, increasing the temperature of the reaction system, and the uncertainty of the amount, etc., can achieve the effect of continuous and stable spinning, stable intrinsic viscosity, and narrow molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

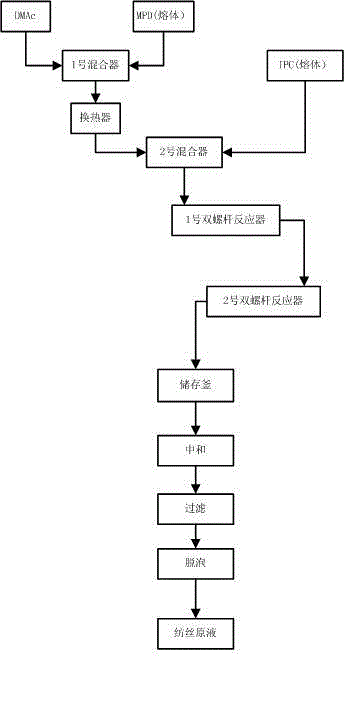

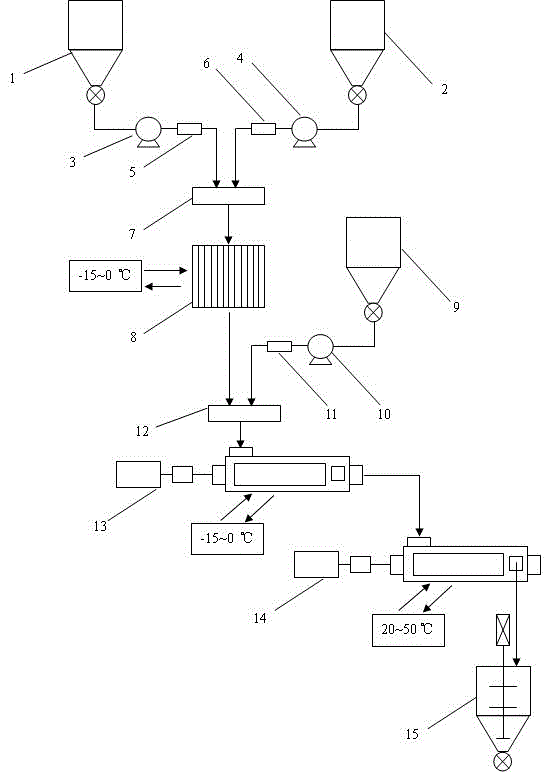

[0035] After the dimethylacetamide (DMAC) solvent is conveyed by a precision gear pump and measured by a mass flow meter, it is continuously added to the No. 1 No. Quickly mix in the mixer to prepare the MPD solution. The MPD solution flows into the plate heat exchanger to cool the temperature to -10°C. The cooled MPD solution and the 185.15kg / h flow rate of isophthaloyl chloride (IPC) melt are continuous at the same time Add it into the No. 2 mixer for rapid mixing, and the mixed solution flows into the No. 1 twin-screw reactor with a screw diameter of 60mm, an aspect ratio of 30, a rotating speed of 360r / min, and a jacket temperature of -15°C. Reaction in this reactor 2min forms oligomer, and oligomer further flows into the second twin-screw reactor that screw diameter is 125mm, aspect ratio is 10, rotating speed is 150rpm, jacket temperature is 25 ℃, in this reaction React in the container for 8 minutes to form a polym-phenylene isophthalamide solution. After the solution i...

Embodiment 2

[0037]After the dimethylacetamide (DMAC) solvent is transported by a precision gear pump and measured by a mass flow meter, it is continuously added to the first No. Quickly mix in the mixer to prepare the MPD solution. The MPD solution flows into the plate heat exchanger to cool the temperature to -10°C. The cooled MPD solution and the isophthaloyl chloride (IPC) melt at a flow rate of 123.44kg / h are continuous at the same time Add it into the No. 2 mixer for rapid mixing, and the mixed solution flows into the No. 1 twin-screw reactor with a screw diameter of 60mm, an aspect ratio of 30, a rotating speed of 360r / min, and a jacket temperature of -15°C. Reaction in this reactor 3min forms oligomer, and oligomer further flows into the second twin-screw reactor that screw diameter is 125mm, length-to-diameter ratio is 10, rotating speed is 100rpm, jacket temperature is 25 ℃, in this reaction React in the container for 15 minutes to form a polym-phenylene isophthalamide solution. ...

Embodiment 3

[0039] After the dimethylacetamide (DMAC) solvent is transported by a precision gear pump and measured by a mass flow meter, it is continuously added to the No. 1 No. Quickly mix in the mixer to prepare the MPD solution. The MPD solution flows into the plate heat exchanger to cool the temperature to -10°C. The cooled MPD solution and the 185.15kg / h flow rate of isophthaloyl chloride (IPC) melt are continuous at the same time Add it into the No. 2 mixer for rapid mixing, and the mixed solution flows into the No. 1 twin-screw reactor with a screw diameter of 60mm, an aspect ratio of 30, a rotating speed of 360r / min, and a jacket temperature of -15°C. Reaction 1.8min forms oligomer in this reactor, and oligomer flows into screw rod diameter further and is that 125mm, length-to-diameter ratio are 10, rotating speed is that 150rpm, jacket temperature are in the second twin-screw reactor of 25 ℃, in this React in the reactor for 7 minutes to form a polym-phenylene isophthalamide sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com