Quick dismounting structure for guide plate of false twist texturing machine

A false-twist texturing machine and guide disc technology, applied in textiles and papermaking, can solve problems such as inconvenient maintenance, affect production efficiency, increase motor failure rate, etc., and achieve improved safety, service life, and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

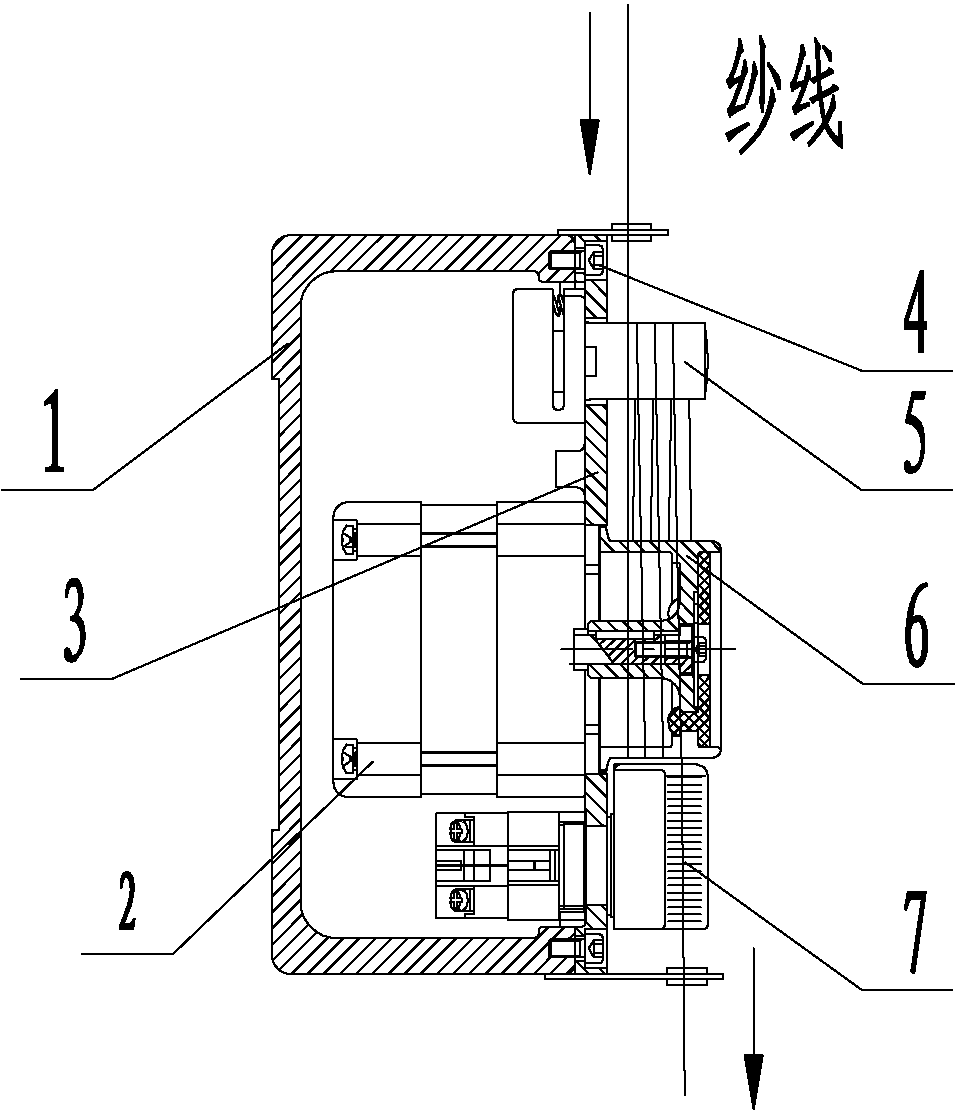

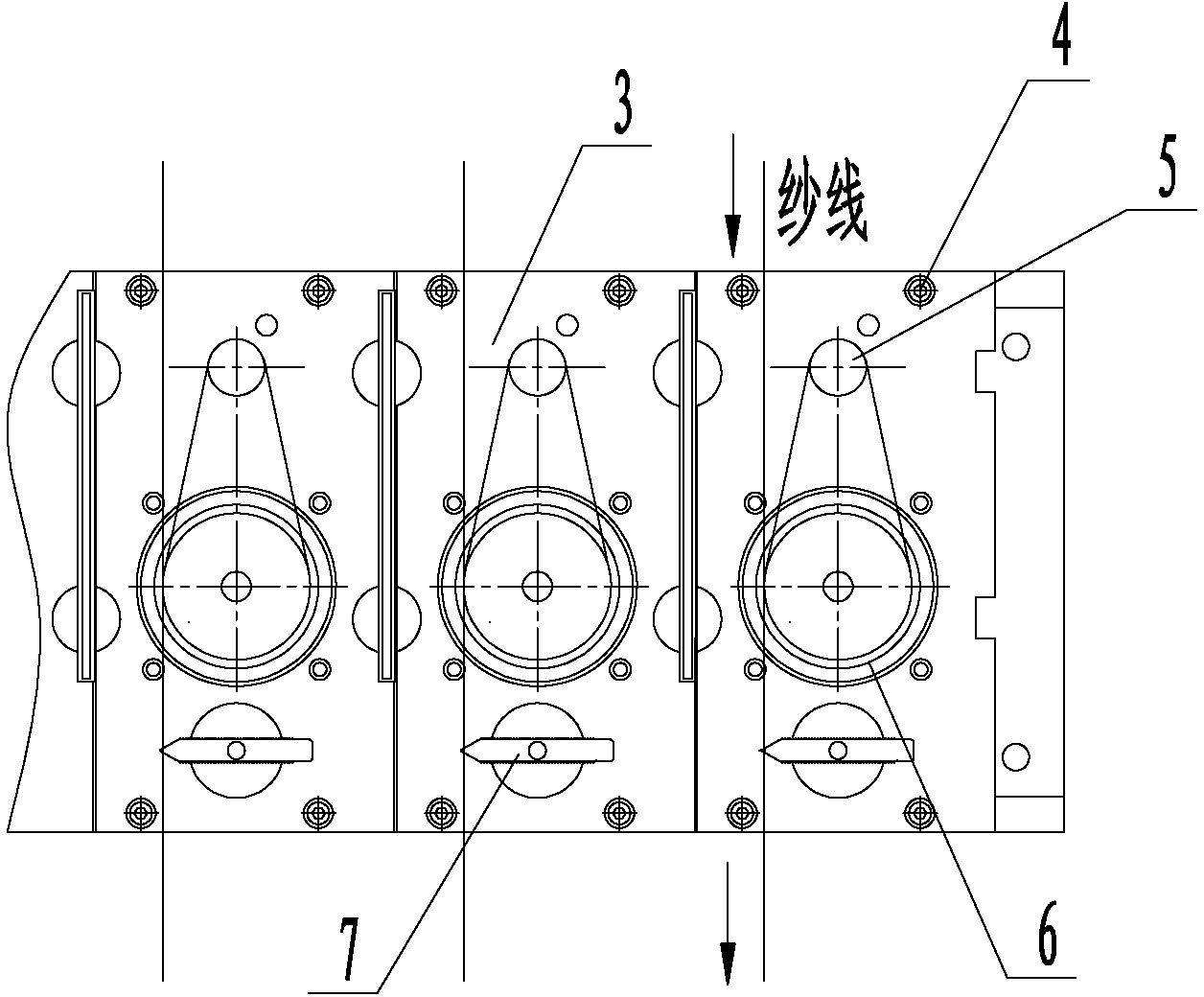

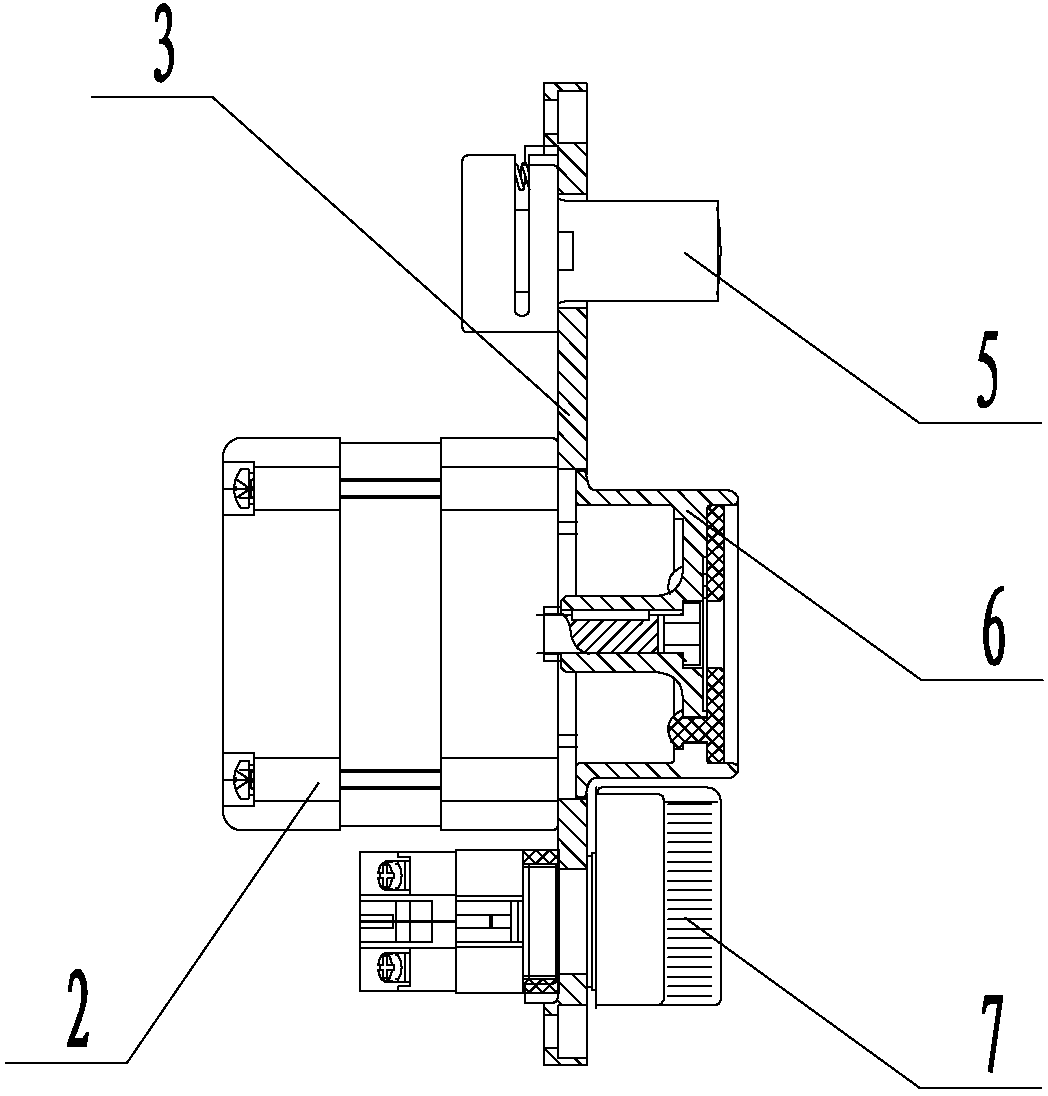

[0027] Such as Figure 1-4 As shown, the present invention is mainly composed of an aluminum beam 1 and a detachable panel 3, and the panel 3 is installed on one side of the aluminum beam 1 by four hexagon socket screws 4. The aluminum beam 1 can be in a "C" shape, and the panel 3 is installed on the side of the opening of the aluminum beam 1 . There are multiple panels 3 , and each panel 3 is correspondingly equipped with a single-spindle synchronous motor 2 , a splitting roller 5 , a godet joint 6 and an automatic stop device 7 . The panel 3 is made of aluminum alloy material to facilitate heat dissipation. The godet joint 6 is installed on the 2 shafts of the single-spindle synchronous motor through a hexagon socket head cap screw. In the cavity of the aluminum beam 1, wires of equipment such as the single-spindle synchronous motor 2 and the automatic stop device 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com