Blocking type mechanical anti-theft lock

A technology of mechanical anti-theft locks and keyholes, which is applied to building locks, cylinder locks, locks with turning keys, etc. It can solve the problems of high manufacturing difficulty and cost, cumbersome unlocking operation process, and reduced mechanical strength. The effect of strong destruction function, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

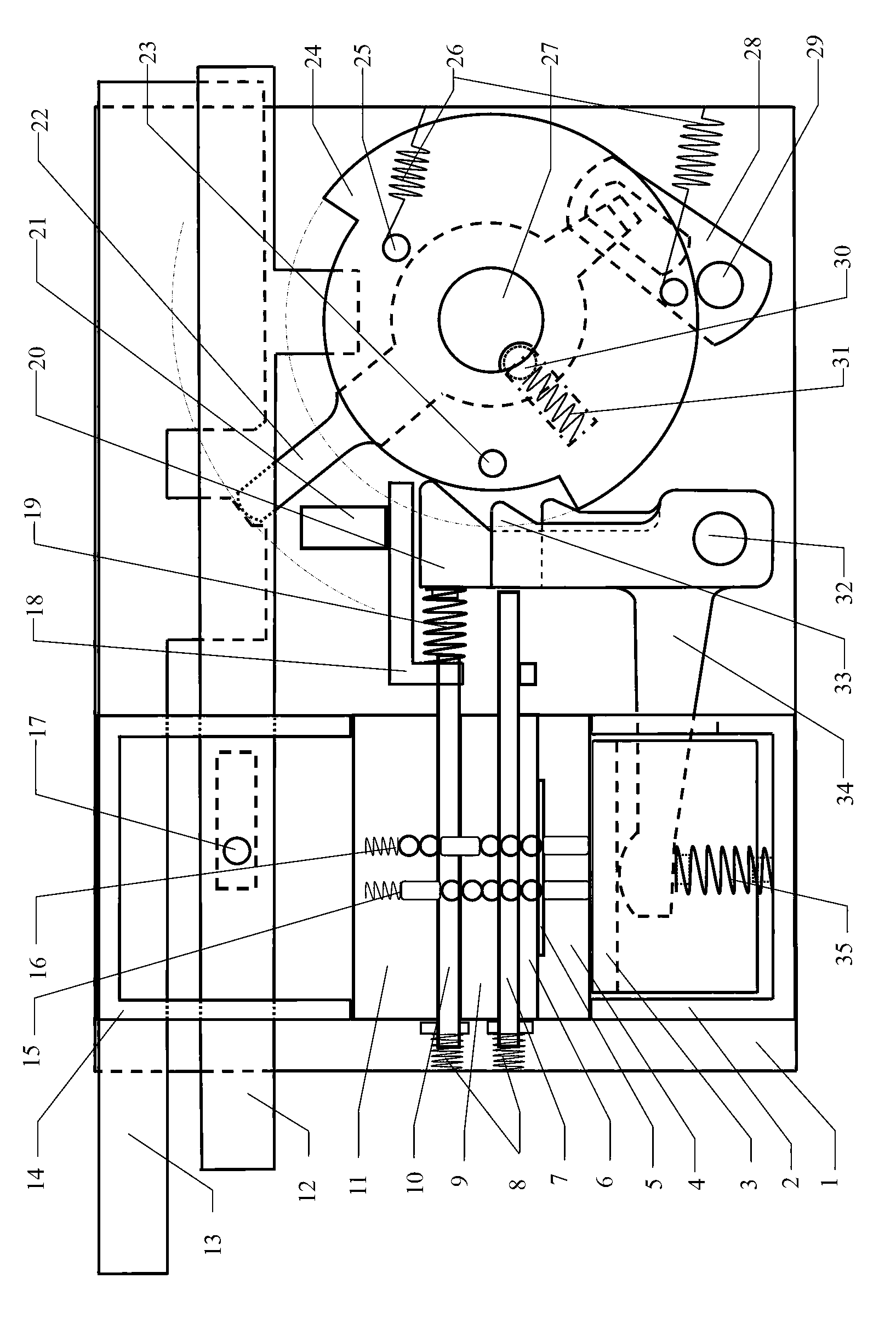

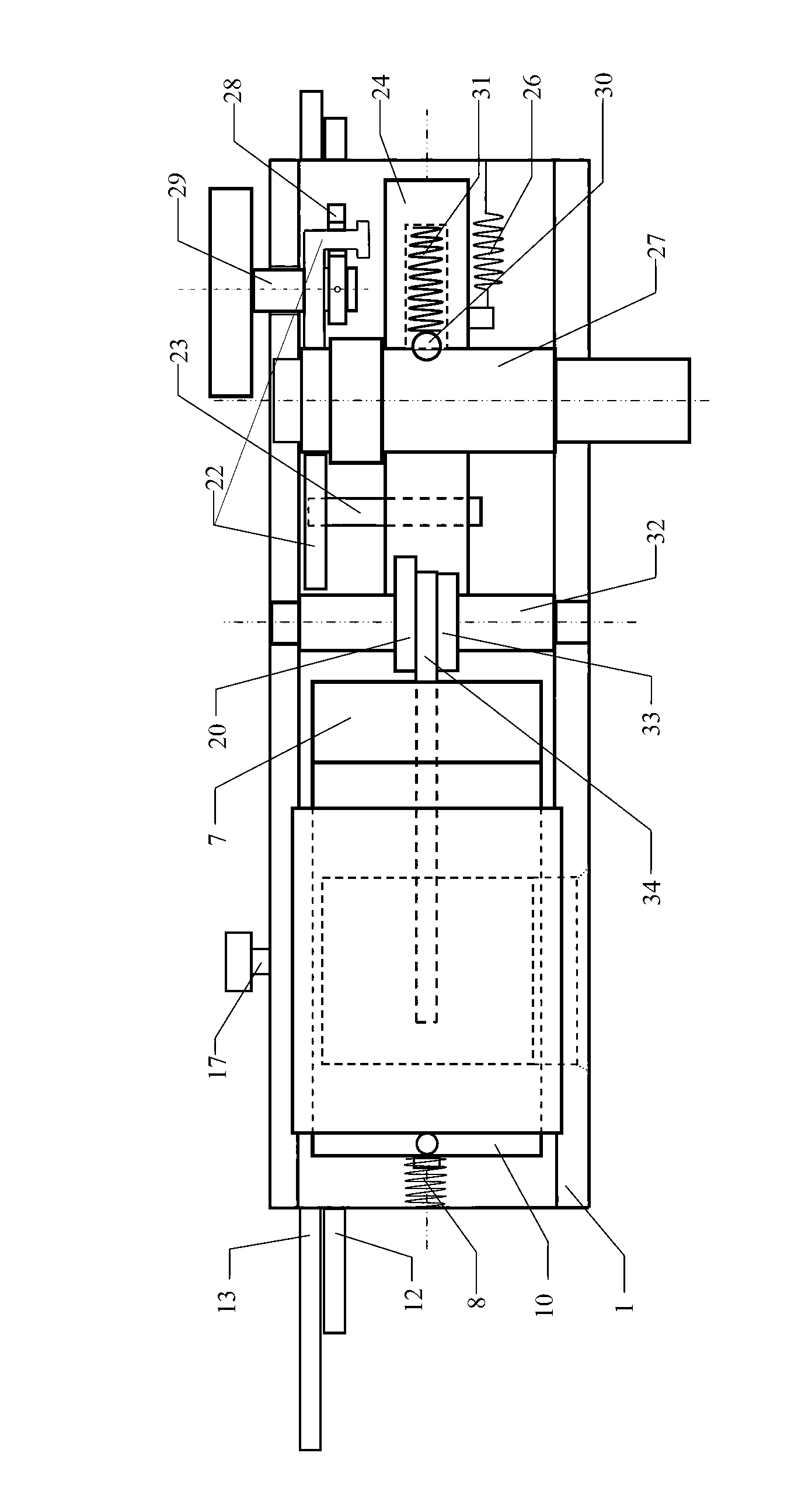

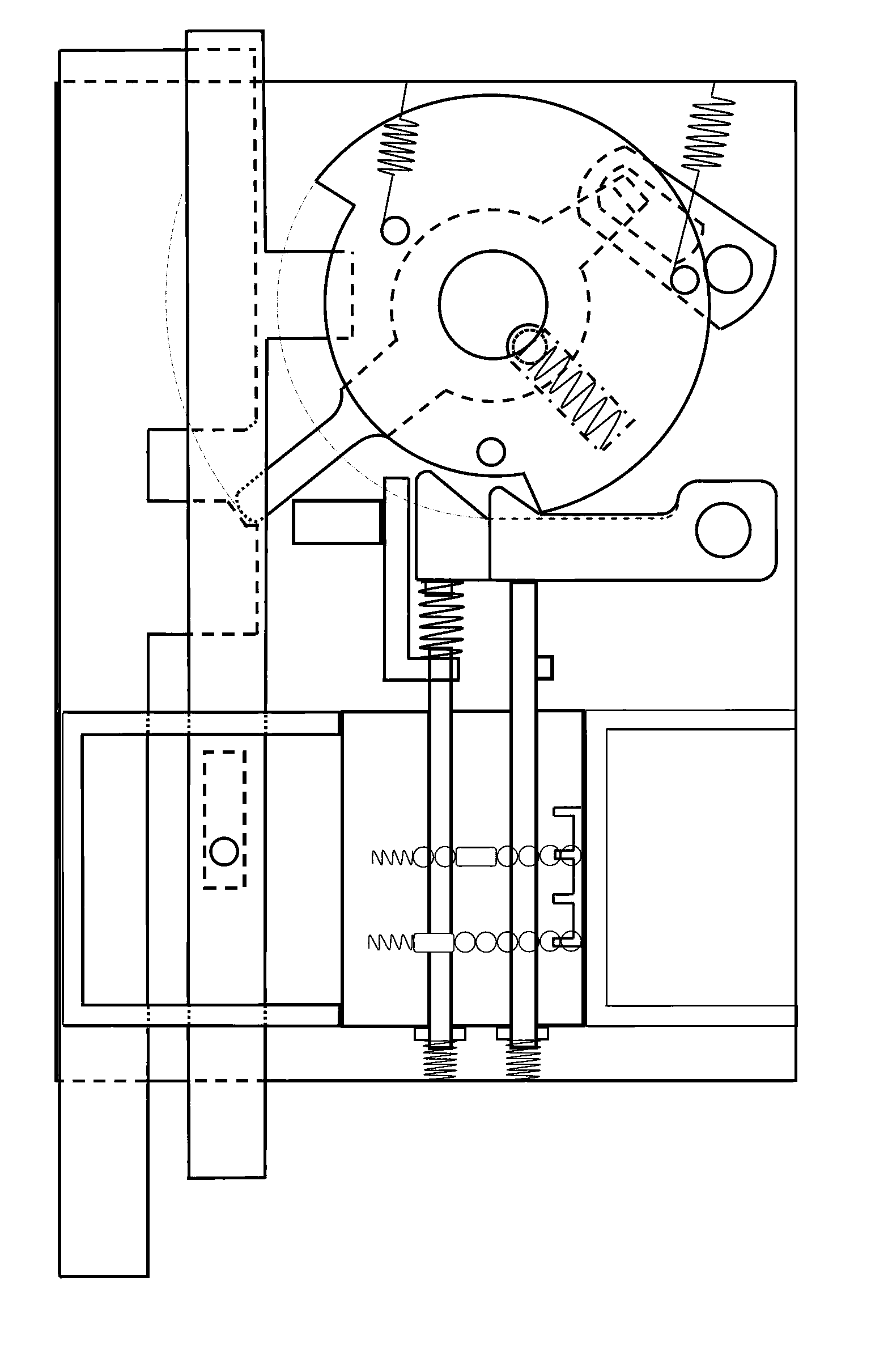

[0070] Combine below figure 1 , figure 2 and image 3 The specific structure and working principle of the barrier type mechanical anti-theft lock proposed by the present invention will be described in detail.

[0071] 1. The lock box (1) is made of steel plates, the thickness of the steel plate at the front is 5mm, the thickness of the steel plate at the back (indoor side) is 4mm, and the thickness of the steel plate around it is 3mm.

[0072] 2. The key is a rectangular sheet with a thickness of 0.5mm, a width of 27mm, a working length of 32mm, and a total length of 55mm. In the upper working area, 24 positions are arranged according to the rules, and 12 positions are randomly selected to open holes with a diameter of 3.2mm. There are 6 rows in the horizontal direction, the distance between the holes is 6.4mm, and the distance between two adjacent holes is 3.2mm. There are 4 rows in the longitudinal direction (the direction of the depth of the keyhole), the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com