Synchronous valve block of bucket wheel machine tail

A technology of synchronous valve and bucket wheel machine, which is applied in the direction of mechanical equipment, servo motor components, fluid pressure actuators, etc., can solve the problems of poor synchronization accuracy, twisted and deformed tail car bracket, and inability to work, so as to reduce the flow adjustment gain, The effect of improving adjustment accuracy and synchronous accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

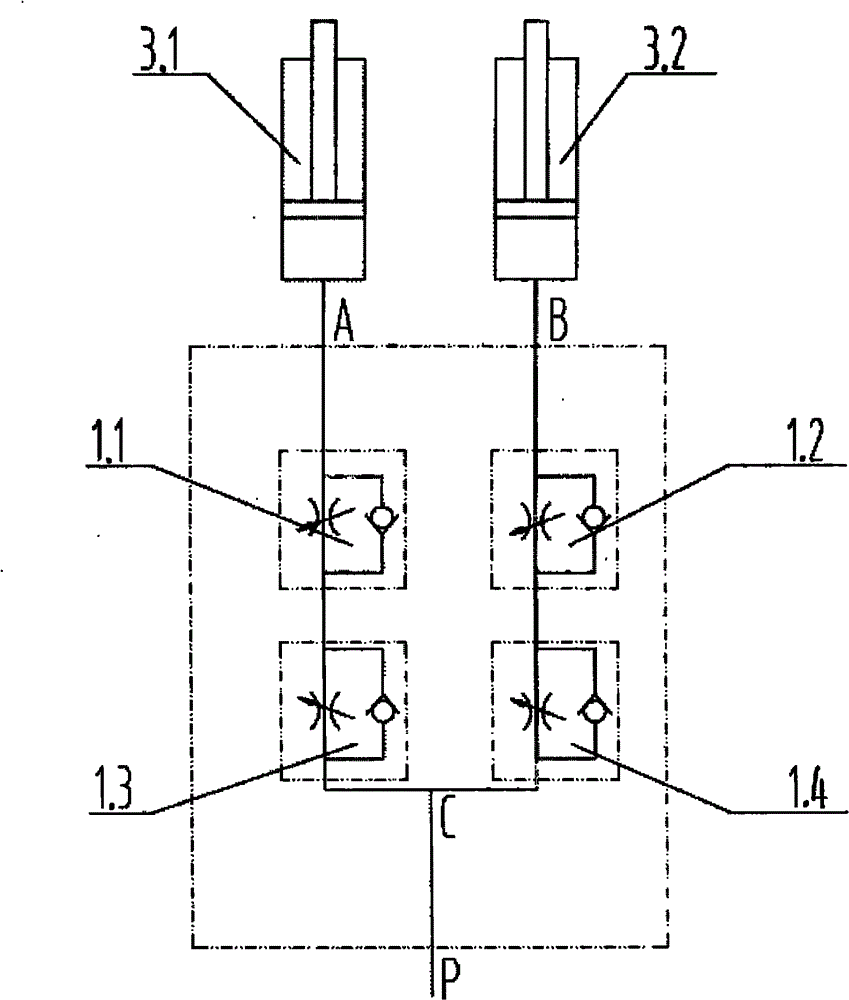

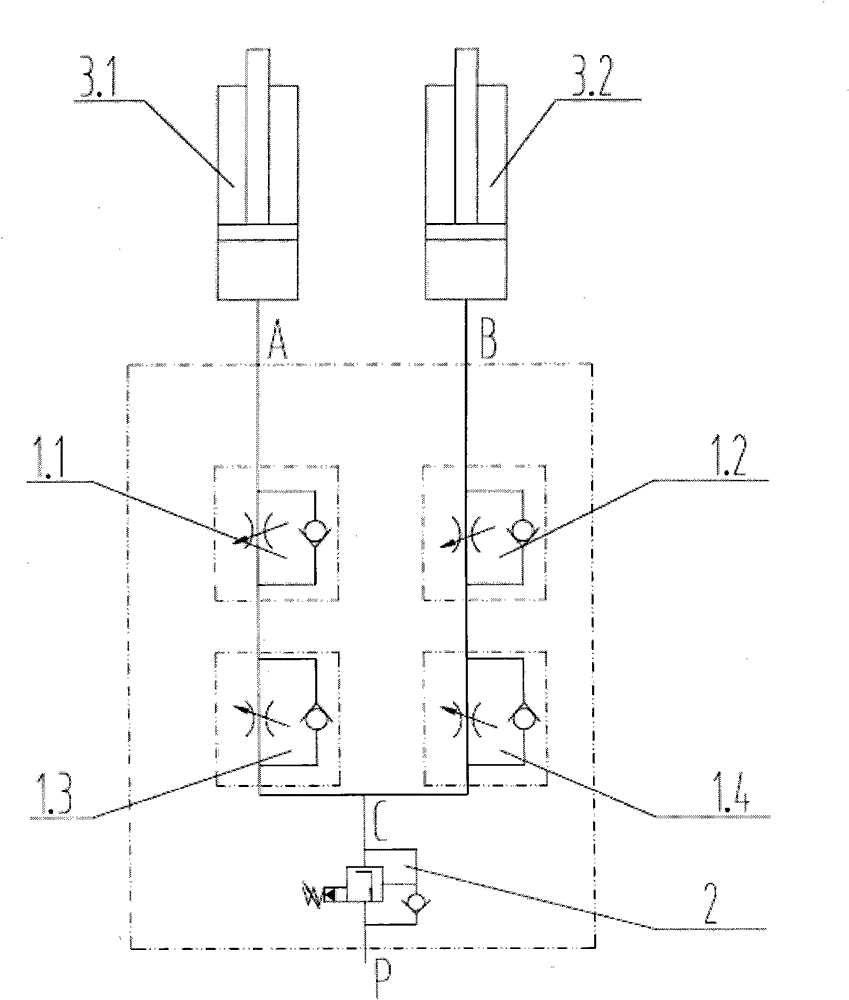

[0008] Embodiment 1: as figure 2 Shown: the synchronous valve group of the tail car of the bucket wheel machine is made up of throttle valve 1.1, 1.2, 1.3, 1.4, balance valve 2 and an integrated block for assembling these valves. When it is necessary to drive the load to rise, the oil enters from the P port. On the one hand, it enters the rodless cavity of the throttle valve 1.3 and throttle valve 1.1 to the hydraulic cylinder 3.1 through the check valve of the balance valve; on the other hand, the oil passes through the balance valve. The check valve of the valve enters the rodless chamber of the throttle valve 1.4, and the throttle valve 1.2 to the hydraulic cylinder 3.2. At this time, the adjustment synchronization mainly relies on the throttle valve 1.3 and the throttle valve 1.4 to play a role, and the balance valve 2 only plays the role of a one-way valve. Because it drives the load to rise, the pressure difference between the front and back of the two throttle valves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com