Valve plate of butterfly valve based on reduction of cavitation damage

A butterfly valve and valve plate technology, applied in the field of butterfly valves, can solve the problems of easy damage to the sealing part of the valve, reduce the bearing capacity of the valve, and affect the normal operation of the valve, and achieve the effects of reducing frictional heat, reducing energy consumption, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

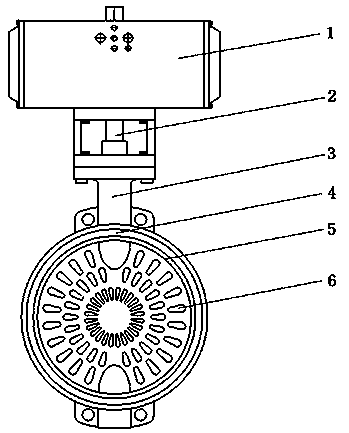

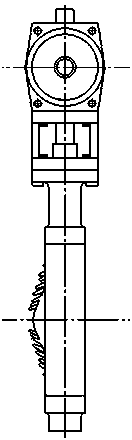

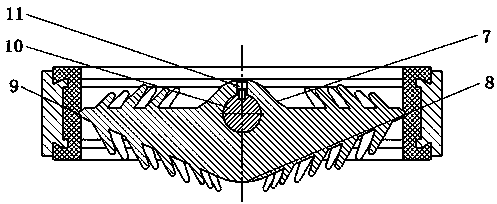

[0022] like figure 1 , figure 2 As shown, a butterfly valve plate based on reducing cavitation damage includes a valve plate opening and closing operating mechanism 1, a valve stem 2, a valve body 3, a gasket 4 and a valve plate 5 with comb teeth 6 on the valve plate 5. Including the rigid sealing surface 9 on the peripheral edge of the valve plate, and the valve stem assembly hole in the middle of the valve plate: such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the cone angle of the rigid sealing surface α for 45°α 60°, the assembly hole in the middle of the valve plate is smaller from the center of the valve plate to the fluid inlet, the valve plate near the fluid inlet is a flat surface, and the valve plate near the fluid outlet is a diversion cone The radius on the flow cone is R 1 , R 2 , R 3 , and the three groups of comb teeth are evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com