Shift handling mechanism with clearance automatic compensating device

A technology of automatic compensation and control mechanism, which is applied in the direction of transmission control, engine components, engine sealing, etc., can solve the problem that hard rod control cannot be arranged, and achieve the effect of compact structure, advanced technology and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

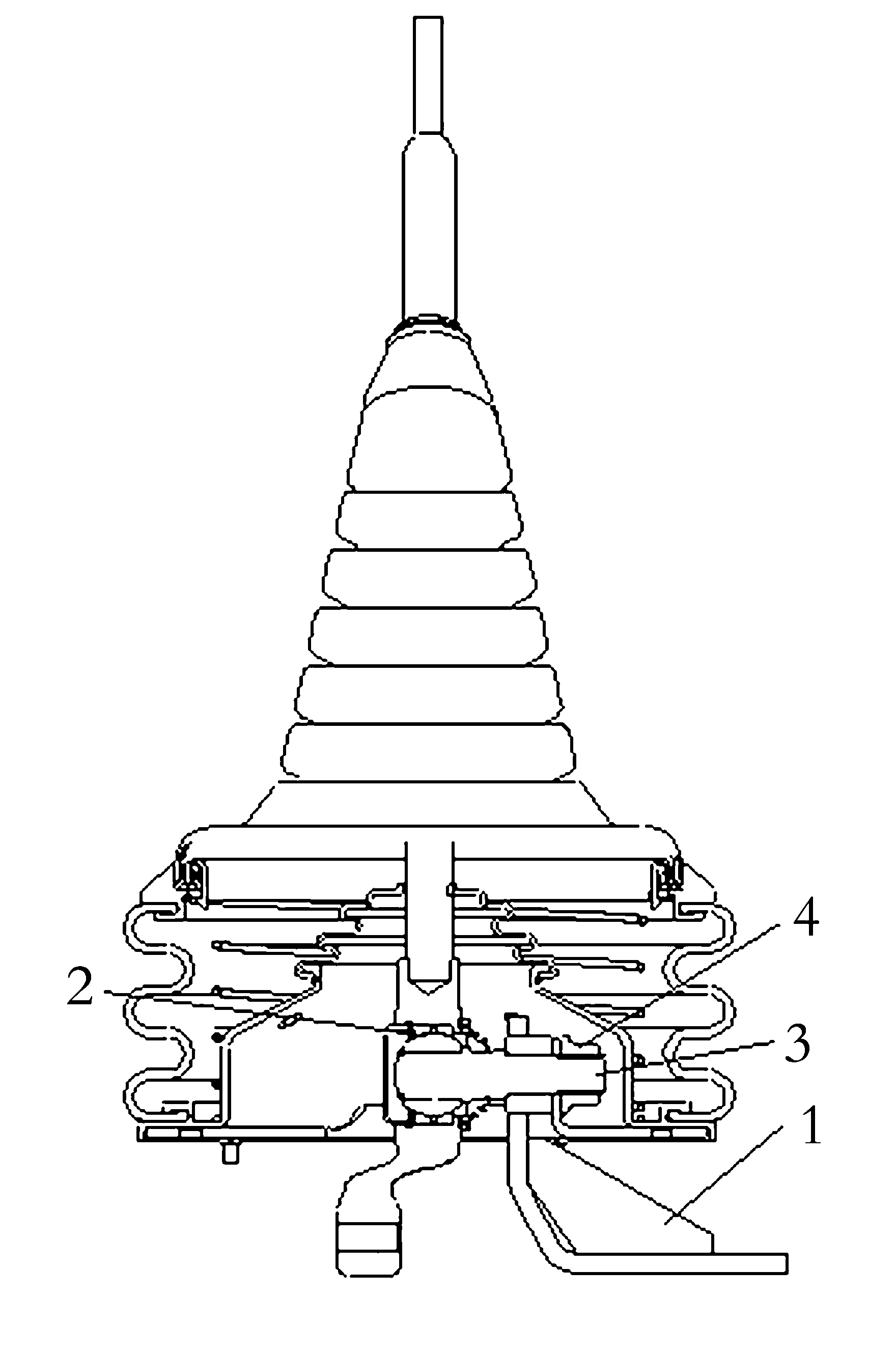

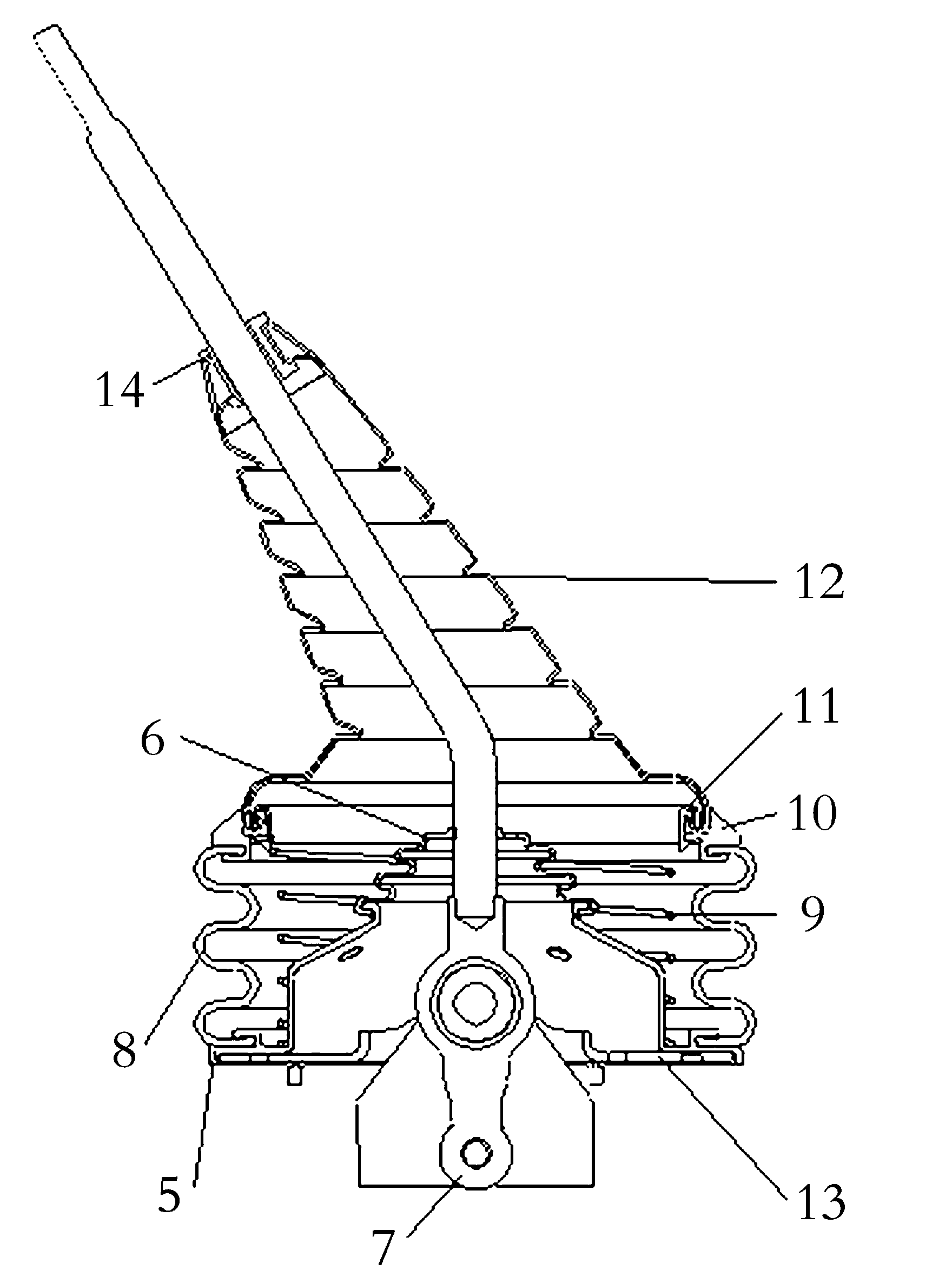

[0021] As shown in the accompanying drawings, a gearshift operating mechanism with an automatic gap compensation device includes a support plate 13, a fixed cover 5 whose lower end is connected to the support plate 13, a small dust cover 6 connected to the upper end of the fixed cover 5, and a small dust cover located on the small dust cover. Joint bearing 2, shift shaft 3, locking flange nut 4, shift lever assembly, bracket assembly in cover 6 and fixed cover 5, and bracket assembly 1 connects shift shaft 3, support plate 13, joint bearing 2. The fixed cover 5 and the like are rigidly fixed on the engine together to play a stable supporting role. A deformation buffer mechanism is arranged outside the small dustproof cover and the fixed cover. The locking flange nut adopts Spirax full-thread locking flange nut. The defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com