Economizer coil hanger for narrow gaps

A hanging device and serpentine tube technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficulty in manufacturing hanging structures, high energy and physical consumption, and high technical requirements for workers, and achieve The effect of considerable economic benefits, strong integrity, and small layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

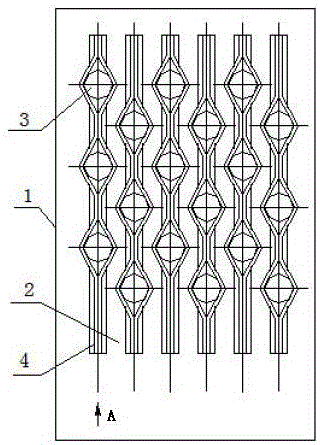

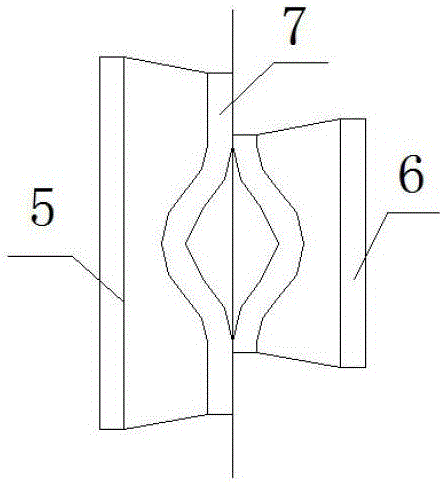

[0022] A serpentine tube hanging device for economizers with narrow gaps: the hanging device 2 is installed in the economizer, and the hanging device includes a group of serpentine tubes 3 arranged in a horizontal staggered arrangement. The hanging device is made up of a set of hanging plates 4, and the hanging plates include wide hanging plates 5, and the wide hanging plates are connected with narrow hanging plates 6, and the wide hanging plates are connected with the described wide hanging plates The narrow hanging plates are connected by fillet welds 7, and the hanging plates include the first hanging plate, the second hanging plate, the third hanging plate to the Nth hanging plate.

Embodiment 2

[0024] Embodiment 1 The economizer serpentine pipe hanging device for narrow gaps, the diameter of the serpentine pipe is 28-51mm, the first hanging plate and the second hanging The center-to-center distance of the hanging boards is 36-59, and the serpentine tubes are installed on the same hanging board at an equal distance of 86-109 mm, and the above-mentioned serpentine tubes are installed on two adjacent hanging boards at an equidistant distance of 41-64 mm. The aforementioned serpentine tube.

Embodiment 3

[0026] For the above-mentioned serpentine tube hanging device for economizers with narrow gaps, the diameter of the serpentine tube is 28mm, and the center distance between the first hanging plate and the second hanging plate is 36. Install the serpentine tubes at an equal distance of 86 mm on the same hanging plate, and install the serpentine tubes at an equidistant distance of 41 mm on two adjacent hanging plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com