Measurement light cone

A technology for measuring light and cones, applied in the field of measuring light cones, which can solve the problems of increasing the uncertainty of the measurement results, reducing the accuracy, repeatability and reliability of the measurement, and difficult to clamp and locate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

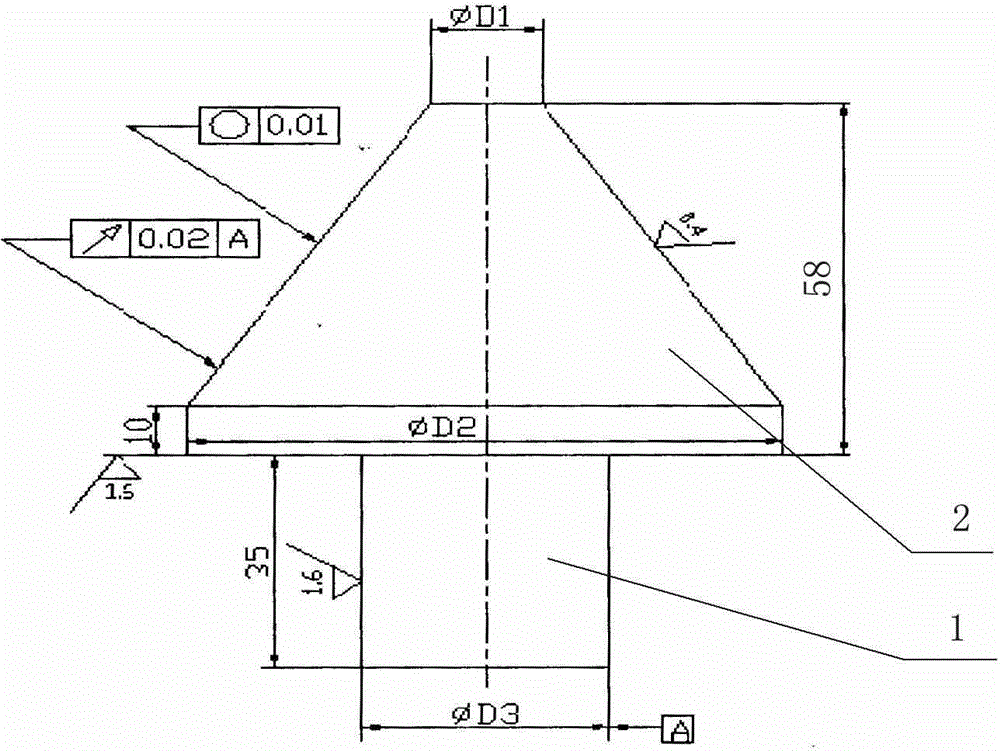

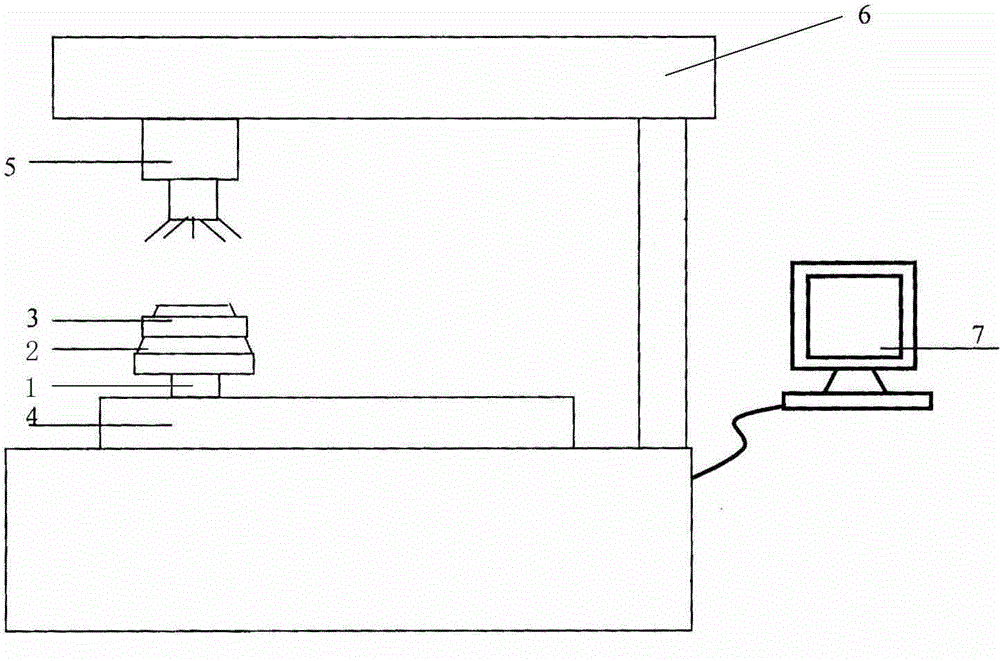

[0014] Such as figure 1 As shown, a measuring light cone is provided with a frustum 2 above the cylindrical pillar 1, and the cylindrical pillar 1 and the frustum 2 are integrally structured, and its material is optical glass; wherein the upper surface of the frustum 2 The diameter D1=7mm, the diameter of the lower surface D2=74mm, the height of the vertebral body is 58mm, the roundness of the side surface is 0.01mm, based on the cylindrical pillar, the side runout of the cone is 0.02mm, and the side surface roughness Ra is 0.4μm; The diameter D3 of the cylindrical pillar 1 is 35 mm, the height is 35 mm, and the side surface roughness Ra is 1.6 μm.

Embodiment 2

[0016] Except that the upper surface diameter D1=70mm of the frustum of conical body 2, the lower surface diameter D2=138mm, and the diameter D3=50mm of the cylindrical pillar 1, the rest of the structure is the same as the first embodiment.

Embodiment 3

[0018] Except that the diameter D1 of the upper surface of the truncated conical body 2 is 134 mm, the diameter of the lower surface is D2 = 200 mm, and the diameter of the cylindrical pillar 1 is D3 = 60 mm, the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com