Grounding claw

A rod body and columnar structure technology, applied in the field of grounding claws that can be welded by welding equipment, can solve the problems of unstable manual welding quality and high defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

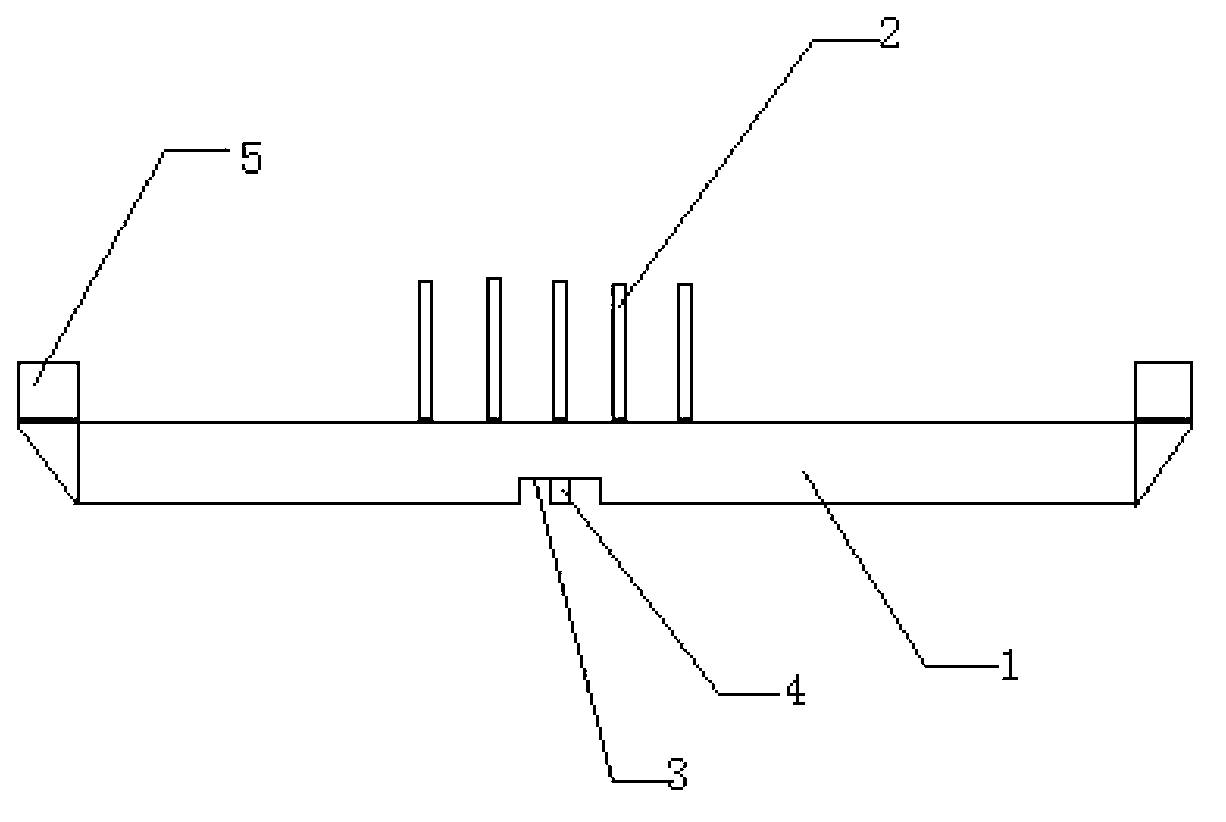

[0011] Such as figure 1 As shown, the present invention includes a long rod body 1, and several columnar structures 2 are arranged in the middle of one side of the rod body 1. The columnar structures 2 are the functional parts of the grounding claws, and are for the electrical short circuit of several PIN positions. There is a notch 3 in the middle of the other side of the rod body 1, and the notch 3 is a welding point of the ground claw. There is a protrusion 4 in the recess 3, and the design of the protrusion 4 is to reduce the metal area to be heated during welding. With the bump 4, the original one notch becomes two notches. When welding, the welding head can directly contact the solder paste, which improves the welding speed.

[0012] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com