Offset printing device

An offset printing and gantry technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to make the transfer cylinder, difficult to achieve the positional accuracy of the electrode pattern, etc., to achieve improved reproducibility, high reproducibility, high position The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described below with reference to the drawings.

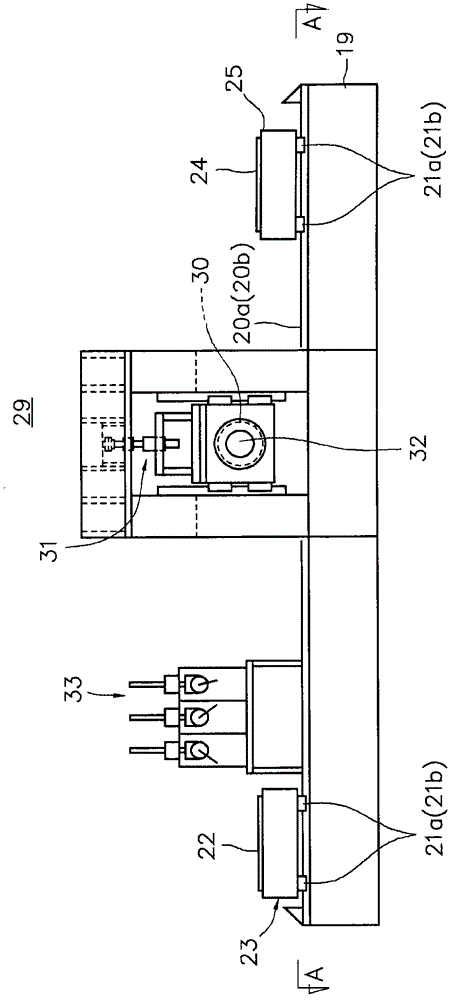

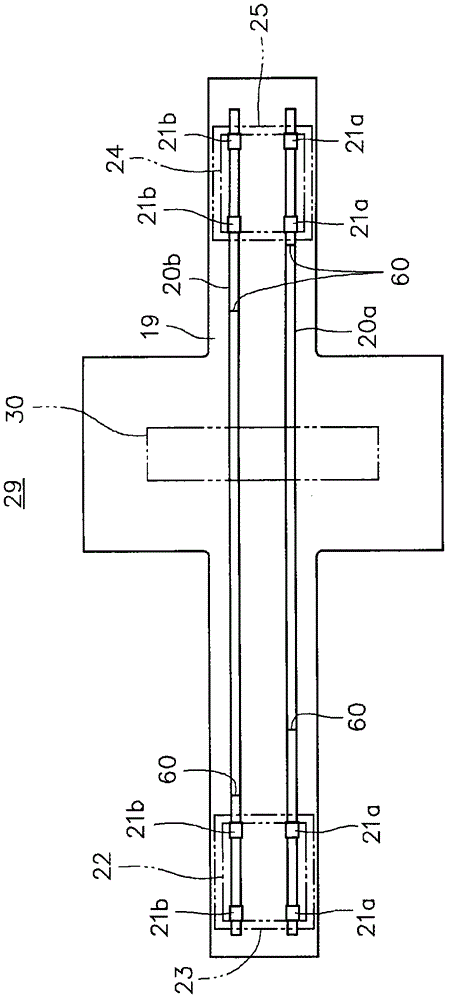

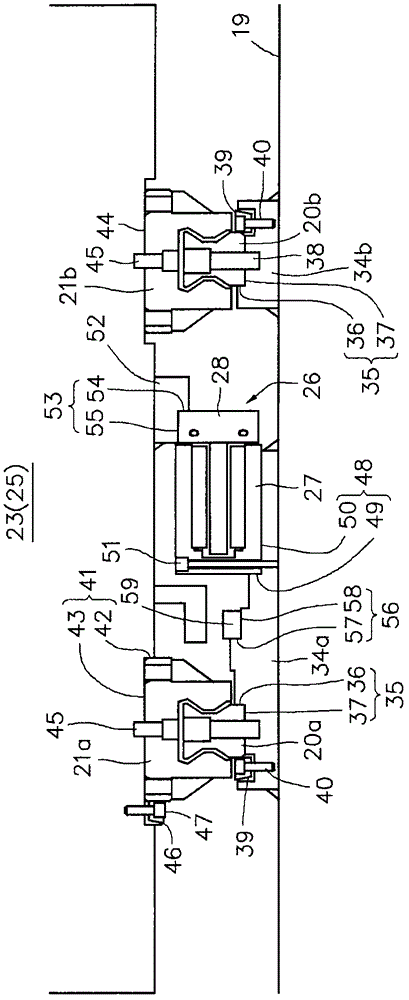

[0064] Figure 1 ~ Figure 3 An offset printing apparatus according to one embodiment of the present invention is shown.

[0065] First, the overall configuration of an offset printing apparatus according to an embodiment of the present invention will be described in outline. The offset printing device includes: a horizontal stand 19; a pair of left and right guide rails 20a, 20b arranged on the upper side of the horizontal stand 19 and extending in one direction (X-axis direction); The printing plate table 23 supporting the flat printing plate 22; the printing object table 25 which is arranged on the upper side of each guide rail 20a, 20b and can support a flat printing object 24 such as a substrate; and the left and right sides arranged on each guide rail 20a, 20b 2 each, 4 guide blocks 21a, 21b in total. The printing plate table 23 and the printing target table 25 are sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com