Drum-type washing machine

A drum-type washing machine and shell technology, which can be applied to other washing machines, dishwashing machines/washing machines, washing devices, etc., can solve the problems of abnormal noise, increased vibration of the side panel 36, vibration of the side panel 36, etc., and achieve high rigidity , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

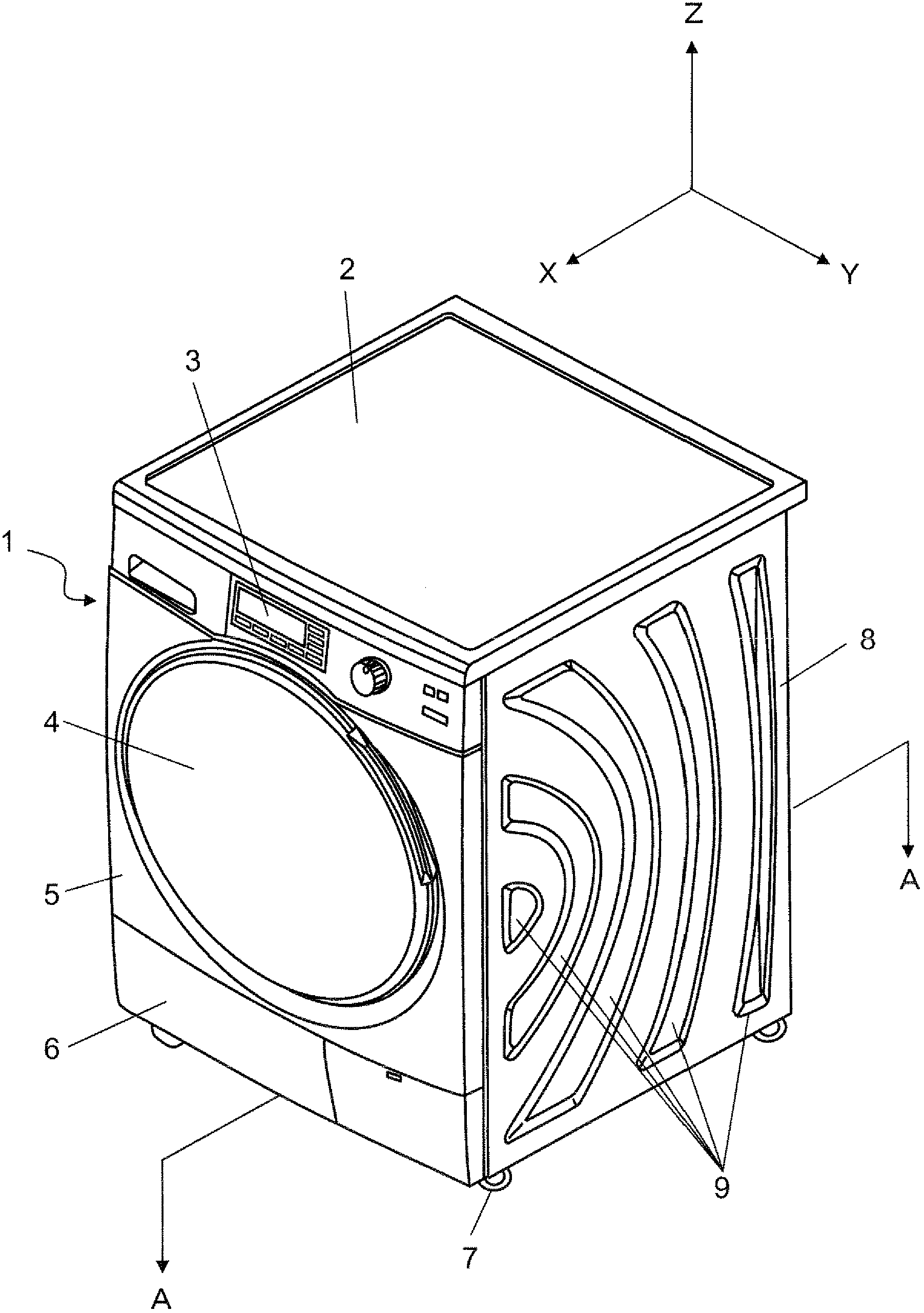

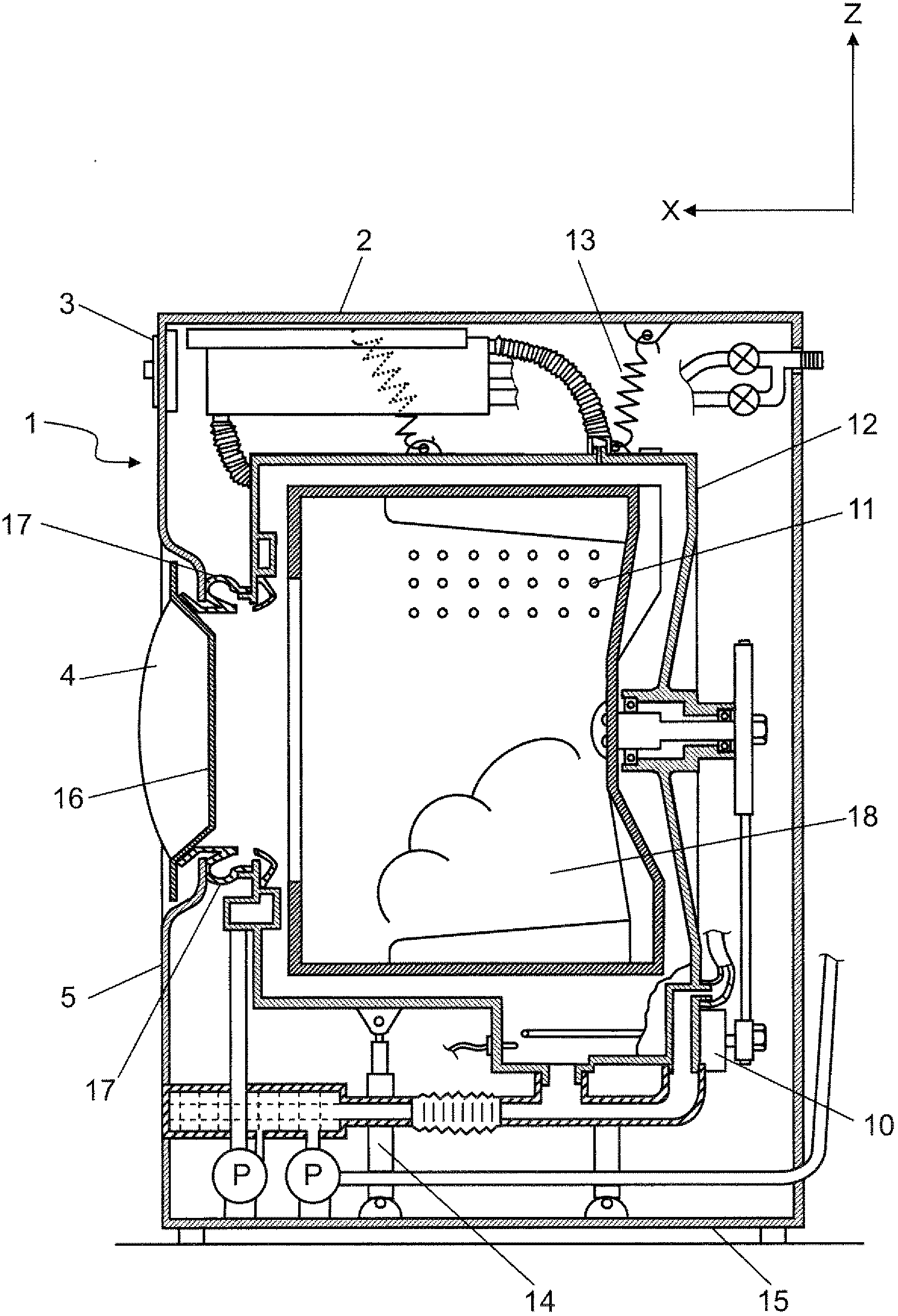

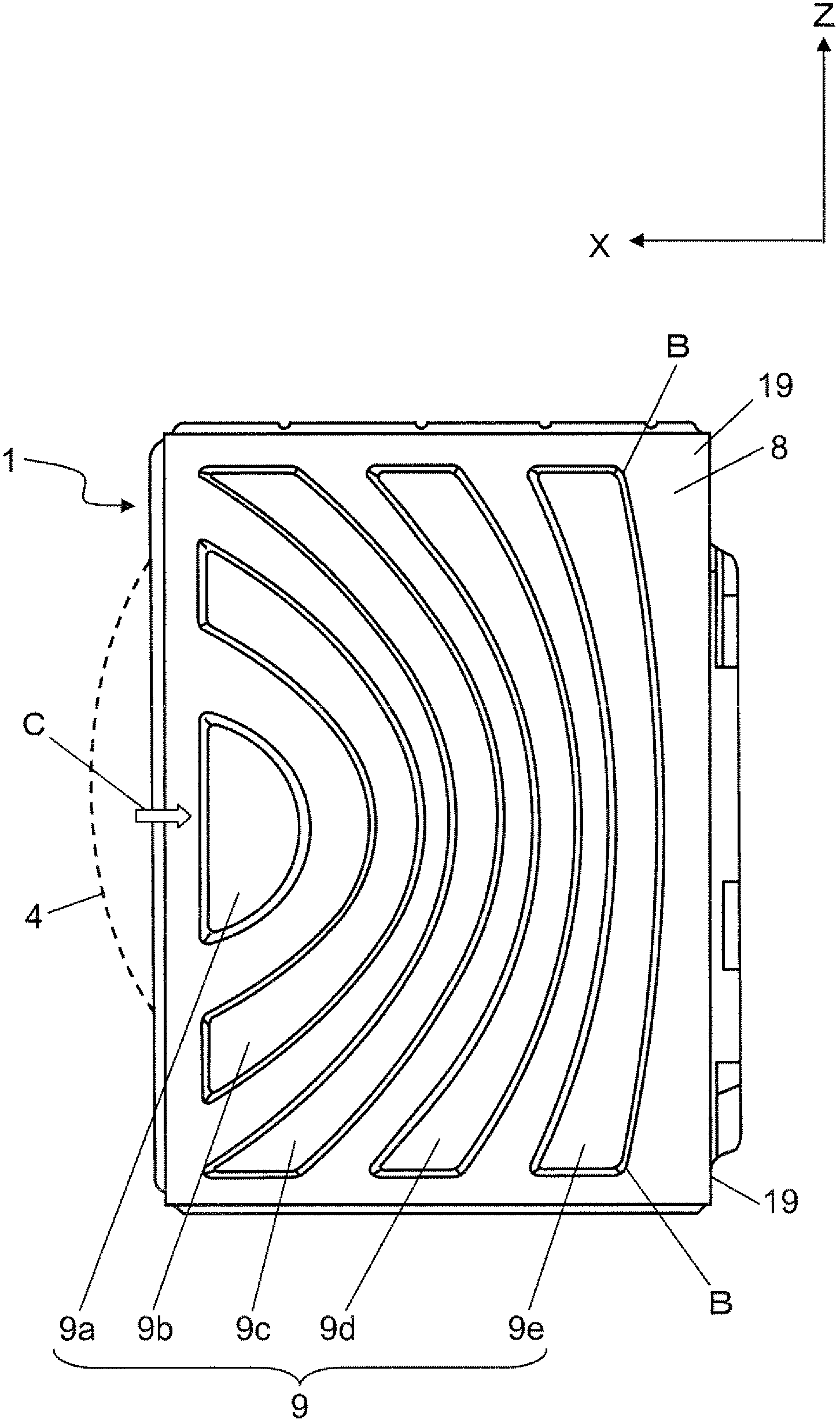

[0027] figure 1 Is an external perspective view of a drum-type washing machine according to an embodiment of the present invention, figure 2 Is the edge of the drum washing machine figure 1 A longitudinal section view of the line A-A, image 3 It is a plan view of the drum-type washing machine viewed from the side.

[0028] in figure 1 Among them, the housing 1 is a roughly rectangular parallelepiped close to a cube. The housing 1 is provided with: an upper surface decoration cover (upper surface cover) 2, which constitutes the upper surface of the housing 1, an operation panel 3, which constitutes the upper part of the front surface of the housing 1, and is also provided with a display screen, etc.; a front surface decoration cover (front surface Cover) 5, which constitutes the front surface of the housing 1, and is provided with a door 4 that can be opened and closed approximately in the center; a lower front surface cover 6, which constitutes the lower part of the front sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com