Torque tool

A tool and torque technology, applied in the field of angle/torque wrench, can solve the problems of rapid dirtying of the clamping unit, increased wear, wrong tripping torque, etc., to prevent pollution or even interference, and prevent foreign matter from intruding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

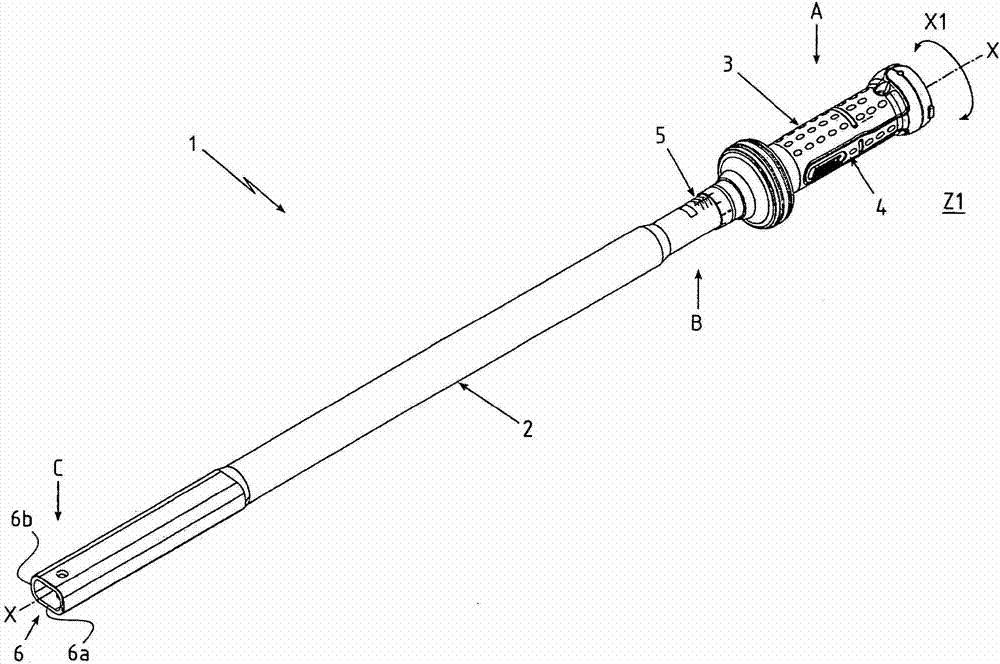

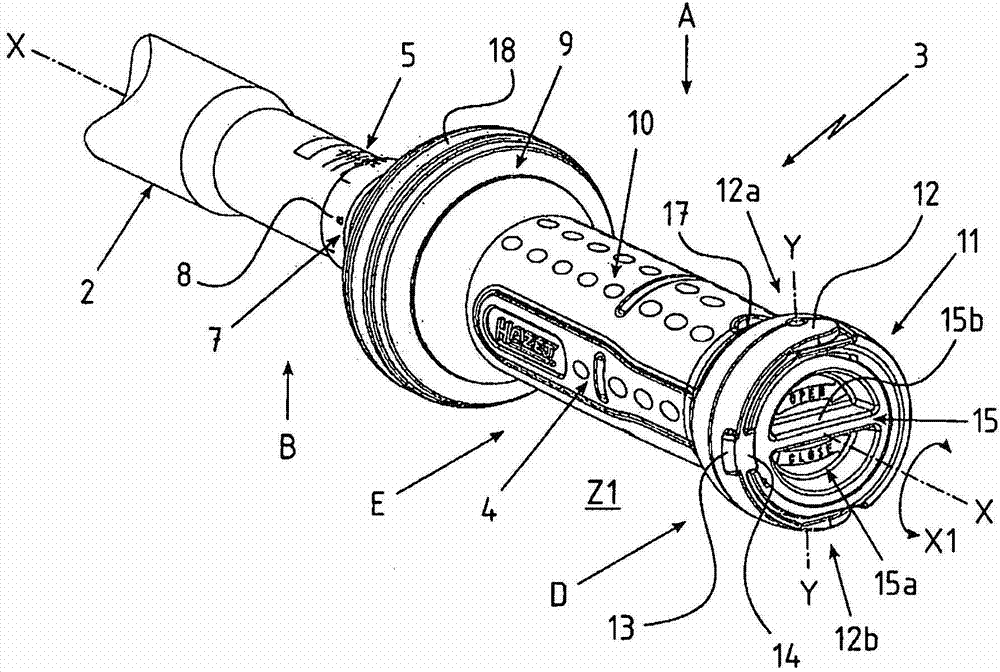

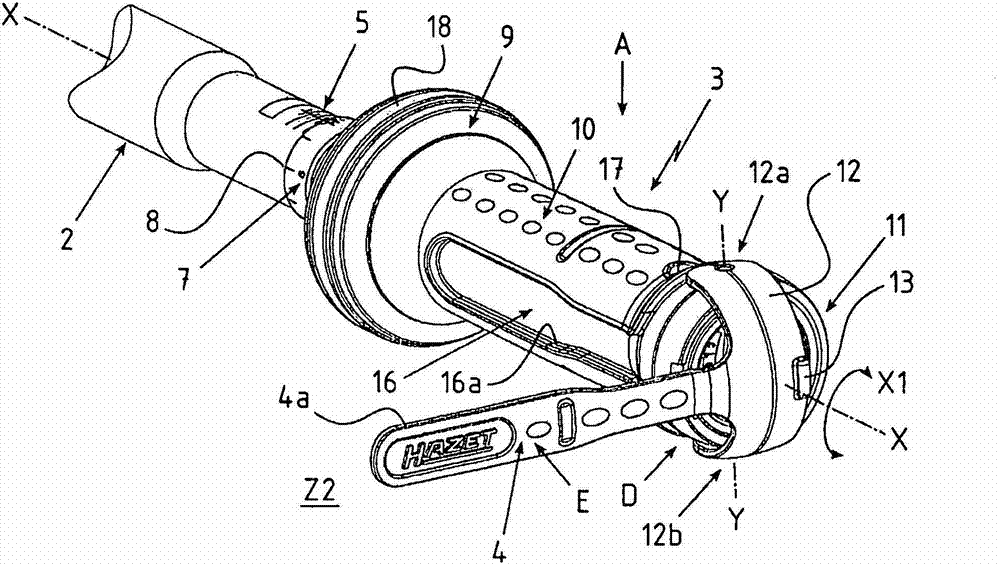

[0053] figure 1 A perspective view of the torque tool 1 according to the invention is shown. Here, now comes the adjustable torque wrench. The torque tool 1 has a tubular tool shaft 2 which extends in its longitudinal direction X. On the Toolbar—About figure 1 In view of the view—the right-hand end section A is provided with a handle 3 , which is rotatably mounted on the tool shaft 2 about the longitudinal axis X in the direction X1.

[0054] The handle 3 is directly or indirectly coupled to a clamping unit (not further shown) within the handle 3 and / or the tool shaft 2 . By turning the handle 3 , in a manner not shown further, the helical spring is clamped or unloaded, via which helical spring the tightening torque to be applied accordingly is preadjusted.

[0055] The handle 3 also has a folding lever 4 which bears against the handle 3 in its now-shown home position Z1 . A scale 5 is provided in the transition region B of the tool shaft 2 to the handle 3 , which can hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com