Twist beam axle provided with Watt linkage

A technology of watt connecting rod and torsion beam shaft, applied in the direction of interconnection system, elastic suspension, vehicle spring, etc., can solve the problems of high cost, increase the overall weight of the torsion beam shaft, complex structure of the watt connecting rod, etc., to reduce the complexity , the effect of high driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In different drawings, the same parts are always given the same reference signs, so these parts are usually only described once.

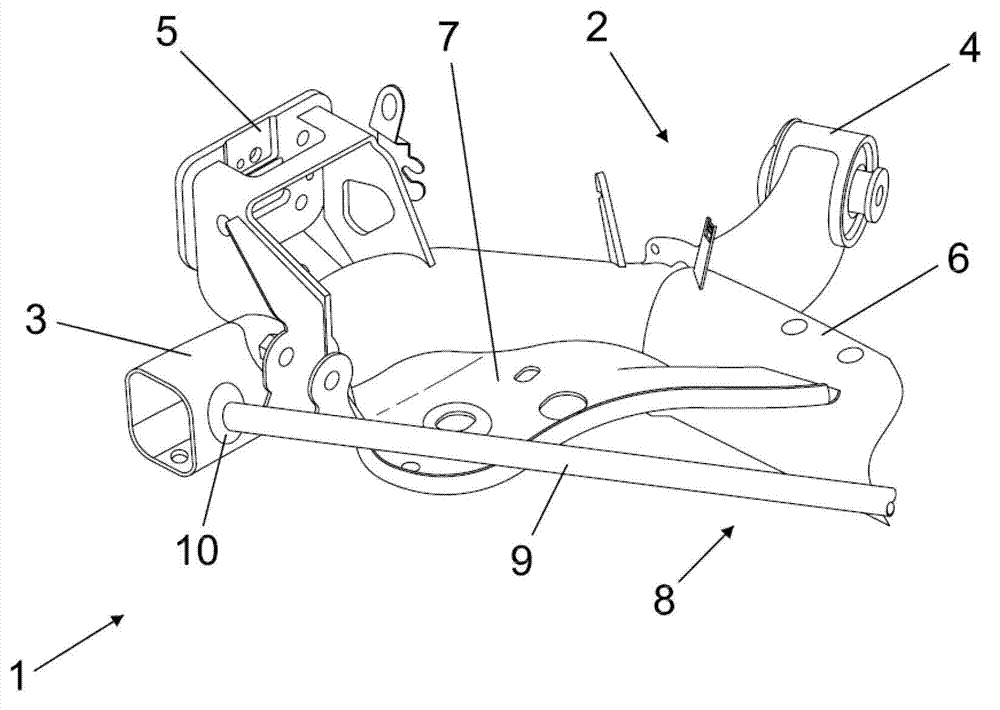

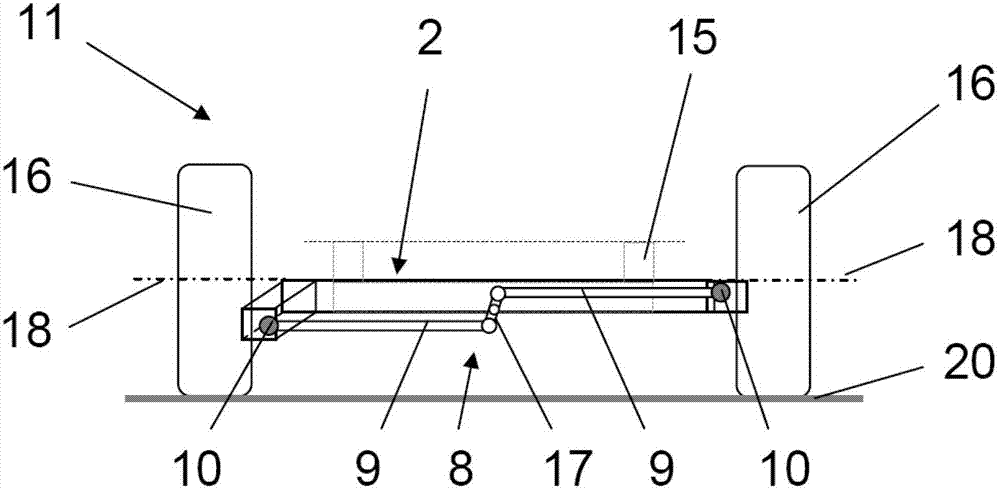

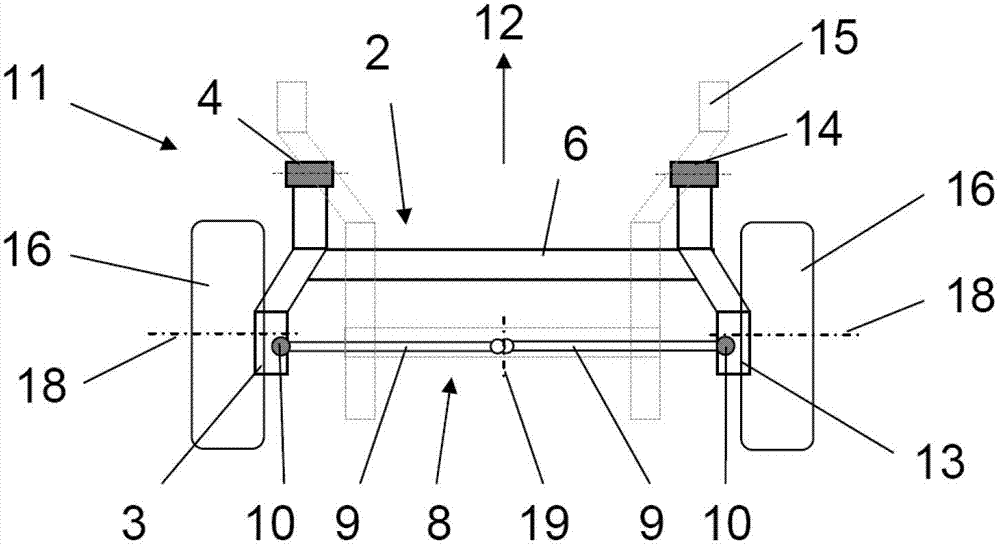

[0047] figure 1 A partial perspective view of an example of a first embodiment of a wheel suspension system 1 for non-steered wheels of a motor vehicle according to the invention is shown. The wheel suspension system 1 includes a torsion beam axle 2 . With respect to the direction of travel of the motor vehicle, figure 1 Only the left part of the torsion beam shaft 2 is shown. Since the torsion beam shaft 2 is designed to be substantially symmetrical with respect to the longitudinal center plane of the vehicle, the left side components of the wheel suspension system 1 described below are correspondingly provided on the right side of the wheel suspension system 1 . In the following description, it is not particularly specified that the specific components of the wheel suspension system 1 are only arranged on one side of the vehicle. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com