Silicate phosphor, manufacturing method thereof, and light generating device

A phosphor and silicate technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problems of low productivity, expensive, size control, separation and grinding in the manufacturing process, and achieve stable emission brightness , the effect of small color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

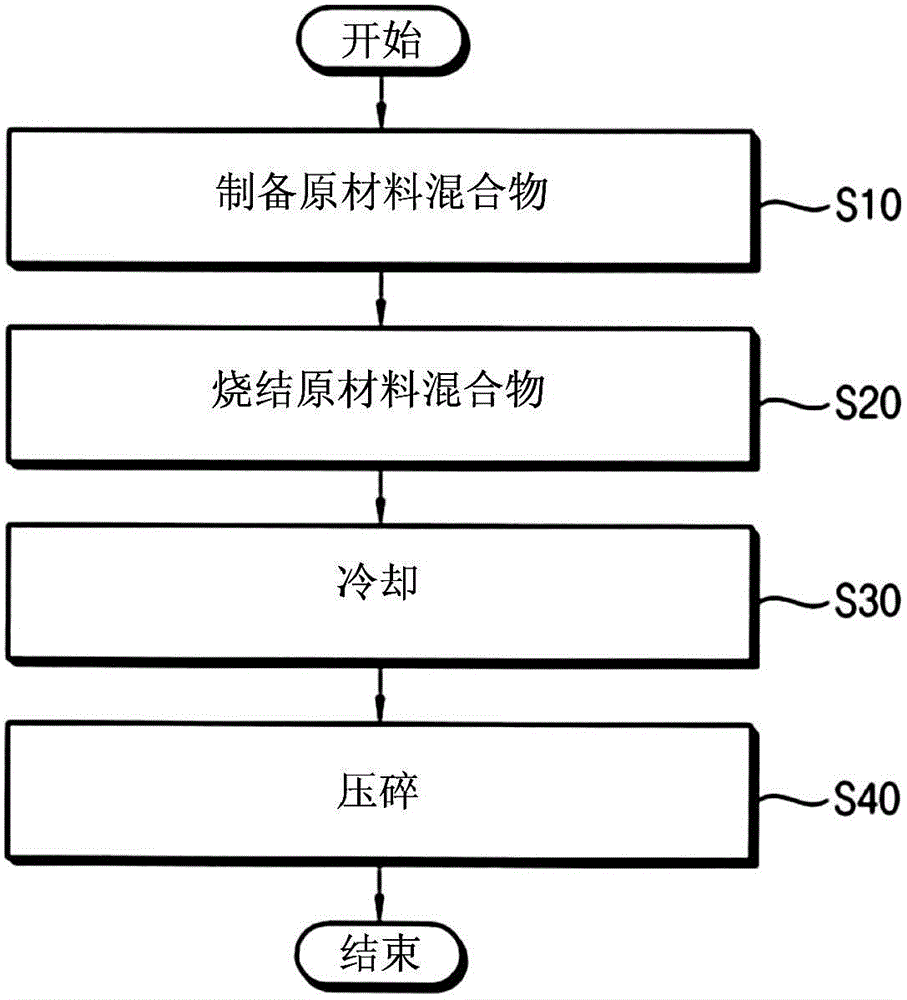

[0095] Weigh CaCO 3 , SiO 2 and Ce 2 o 3 , and mixing them with each other such that CaCO 3 , SiO 2 and Ce 2 o 3 The molar ratios are about 1.97:1:0.015, respectively. The obtained mixture was placed in a melting pot, and the melting pot was placed in an electric stove. Thereafter, the mixture was sintered at about 1450° C. for about 4 hours at about 1 atm with a mixed gas including hydrogen and nitrogen in a volume ratio of about 5:95. Thereafter, the mixture was cooled to room temperature at about 15° C. / minute to obtain a crystalline silicate phosphor composition. The silicate phosphor is uniformly crushed by ball milling to form a silicate phosphor powder.

[0096] Figure 4 is the X-ray diffraction (XRD) profile of Example 1. refer to Figure 4, the powder diffraction pattern of the silicate phosphor of Example 1 agrees with that of the standard material according to JCPDS #87-1257. Therefore, it can be noted that the silicate phosphor of Example 1 has a γ-ph...

example 2

[0103] Weigh CaCO 3 , SiO 2 and Ce 2 o 3 , and mixing them with each other such that CaCO 3 , SiO 2 and Ce 2 o 3 The molar ratios are about 1.99:1:0.005, respectively. A silicate phosphor was obtained from the mixture by substantially the same method as that of Example 1. The silicate phosphor has a γ-phase orthorhombic structure with space group Pbnm62, with Ca 1.99 SiO 4 :0.01Ce 3+ Indicates the silicate phosphor.

example 3

[0105] Weigh CaCO 3 , SiO 2 and Ce 2 o 3 , and mixing them with each other such that CaCO 3 , SiO 2 and Ce 2 o 3 The molar ratios are about 1.98:1:0.01, respectively. A silicate phosphor was obtained from the mixture by substantially the same method as that of Example 1. The silicate phosphor has a γ-phase orthorhombic structure with space group Pbnm62, with Ca 1.98 SiO 4 :0.02Ce 3+ Indicates the silicate phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com