Paper for daily use with mosquito repellent function and production method thereof

A technology for household paper and its production method, which is applied in the fields of paper, papermaking, and special paper, and can solve the problems of waste of mosquito repellent components and low use efficiency, so as to prolong the effective time, avoid waste, and slow down the rate of outward release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

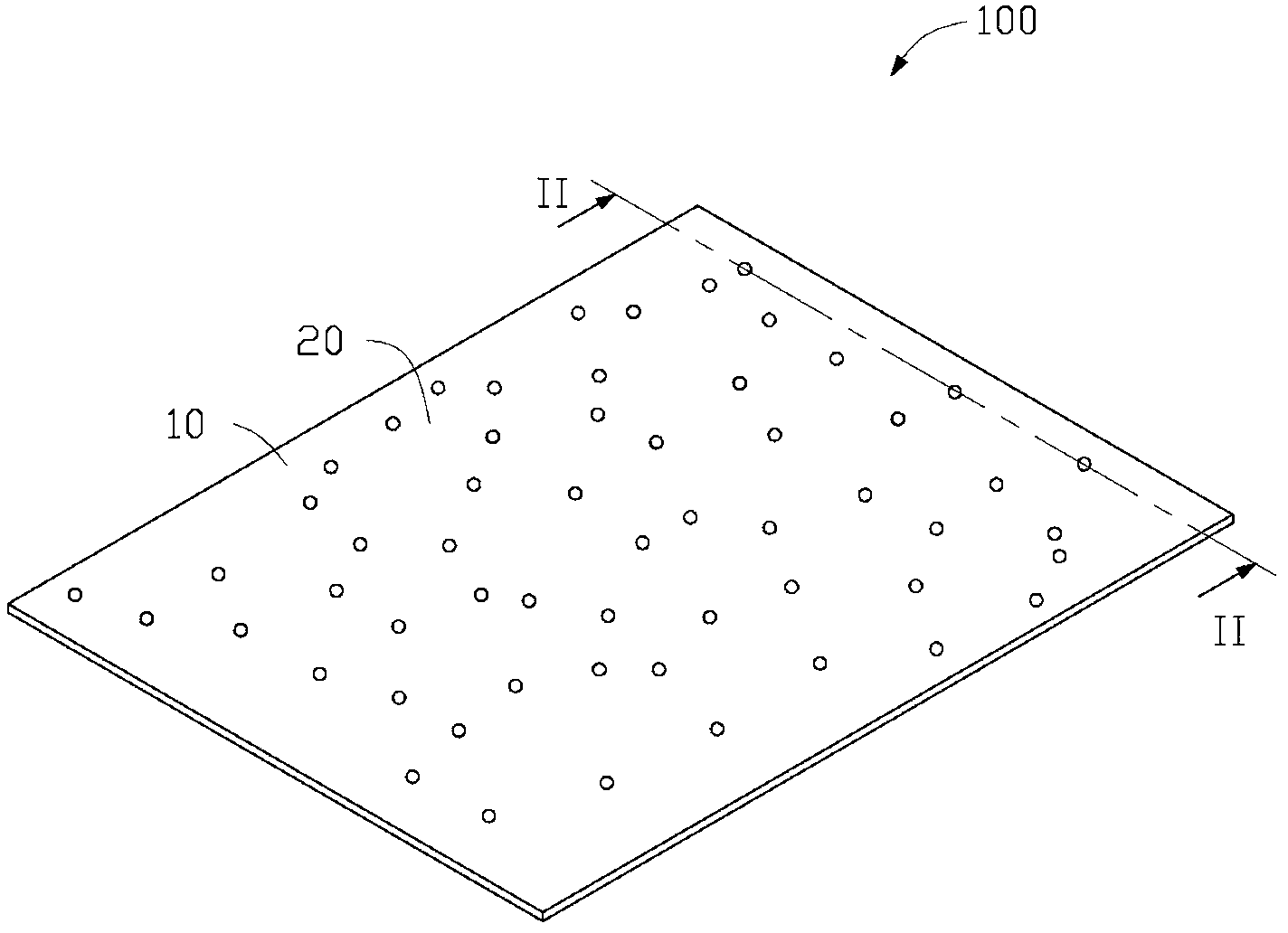

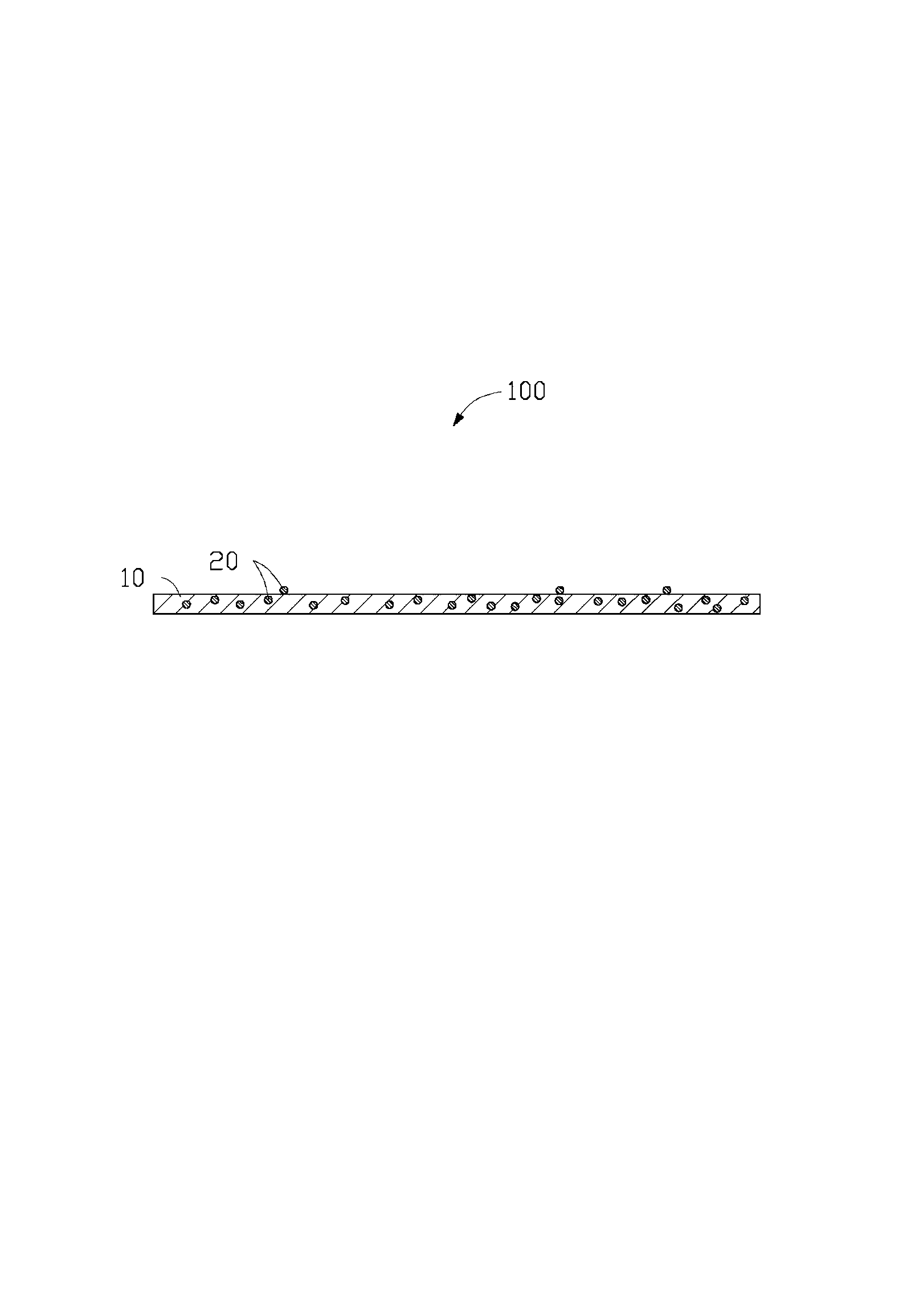

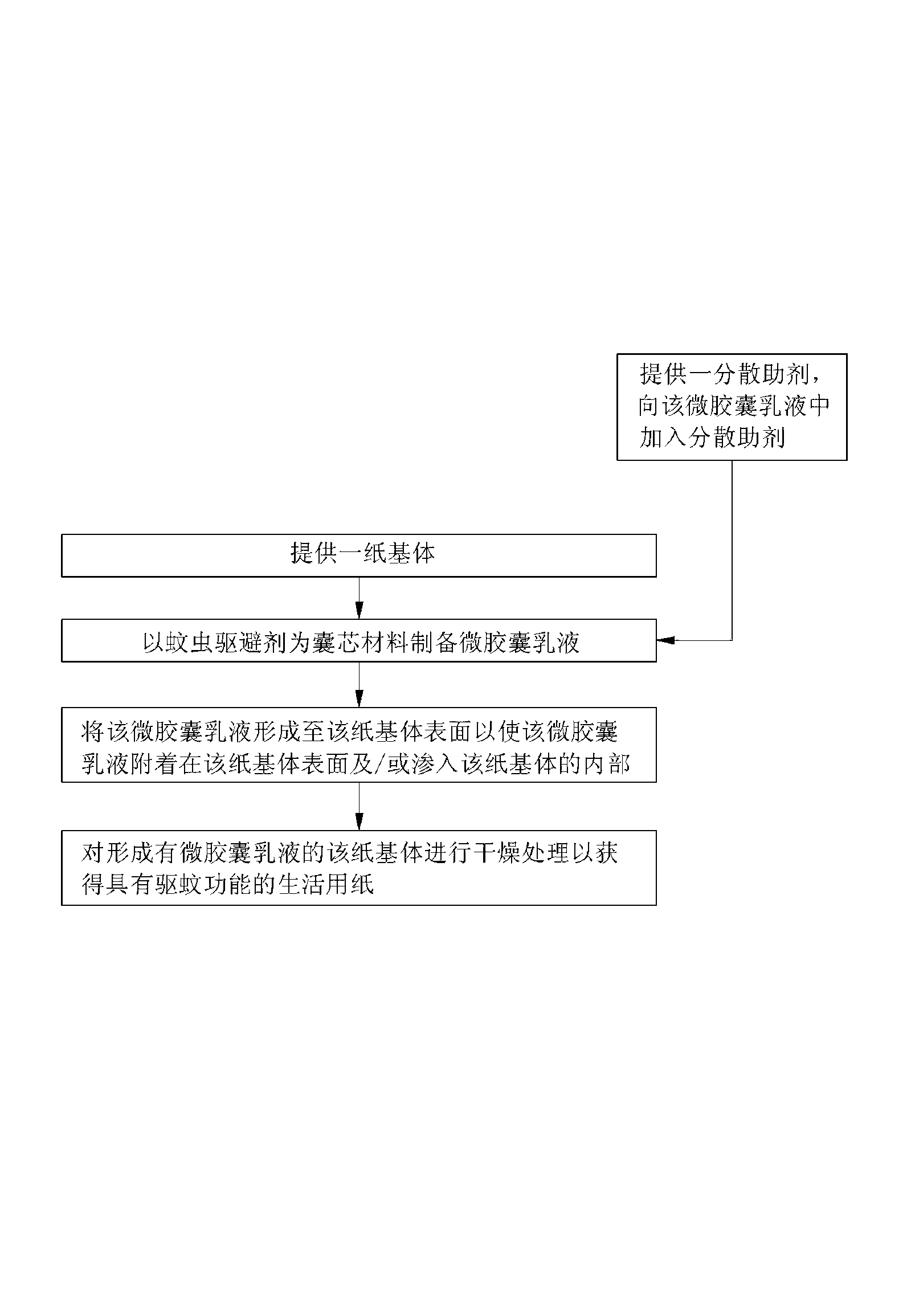

[0043] like image 3 As shown, the preferred preparation method of the above household paper includes the following steps.

[0044] (1): Provide a paper substrate, such as facial tissue, handkerchief paper, toilet paper, roll toilet paper, wet tissue paper and other household paper.

[0045] (2): Prepare microcapsule emulsion with mosquito repellent as capsule core material.

[0046] (3): Provide a dispersion stabilizer, and add the dispersion stabilizer to the microcapsule emulsion.

[0047] Preferably, the added amount of the dispersion stabilizer accounts for 5% to 50% of the total mass of the microcapsule emulsion. For example, the ratio of the mass of the microcapsule dispersion stabilizer to the total mass of the microcapsule emulsion is 20:100, that is, 20 mass parts of the microcapsule dispersion stabilizer is added to 100 mass parts of the microcapsule emulsion. It can be understood that the dispersion stabilizer may not be added to the microcapsule emulsion.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com