Long stroke magnetic suspension shock absorber

A magnetic levitation and long-stroke technology, applied in the direction of spring/shock absorber, magnetic spring, spring, etc., can solve the problems of small magnetic levitation force, noise transmission, short stroke, etc., achieve stable mechanism, increase stroke, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

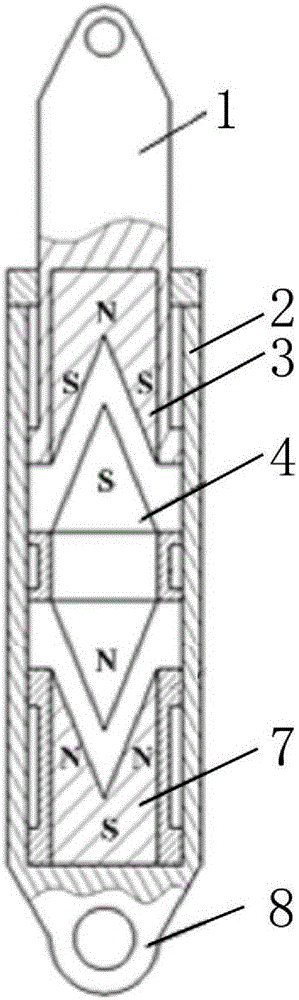

Embodiment 1

[0022] Such as figure 1 As shown, the long-stroke magnetic suspension shock absorber includes a shock absorber 2, an upper ring 1 and a lower ring 8, the upper ring 1 is connected with the shock absorber 2 by sliding, the lower ring 8 is fixedly connected with the shock absorber 2, and the top is permanently connected. The magnet 3 is connected with the upper suspension ring 1, the bottom permanent magnet 7 is connected with the lower suspension ring 8, and a conical floating permanent magnet A4 is connected with the shock absorber 2 in sliding fit, and is suspended between the top permanent magnet 3 and the bottom permanent magnet 7 in balance , the top permanent magnet 3 and the bottom permanent magnet 7 are provided with notches that can be adapted to the conical suspended permanent magnet A4.

[0023] During shock absorption, the upper ring 1, the top permanent magnet 3 and the conical suspension permanent magnet A4 reciprocate in the shock absorber 2 to achieve the purpos...

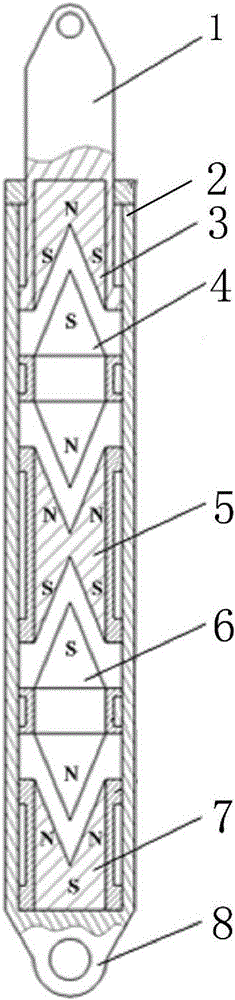

Embodiment 2

[0025] Such as figure 2 As shown, the long-stroke magnetic suspension shock absorber includes a shock absorber 2, an upper ring 1 and a lower ring 8, the upper ring 1 is connected with the shock absorber 2 by sliding, the lower ring 8 is fixedly connected with the shock absorber 2, and the top is permanently connected. The magnet 3 is connected with the upper suspension ring 1, and the bottom permanent magnet 7 is connected with the lower suspension ring 8. In the shock absorber 2, the conical suspension permanent magnet A4, the concave side suspension permanent magnet A5, and the conical suspension permanent magnet B6 are kept balanced and suspended in turn. Between the top permanent magnet 3 and the bottom permanent magnet 7, both the top permanent magnet 3 and the bottom permanent magnet 7 are provided with a notch that can fit with the conical suspended permanent magnet A4.

[0026] When shock absorbing, through the hanging ring 1, the top permanent magnet 3 and the conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com