Batch calibration method and device for air pressure sensors

A technology of air pressure sensor and calibration device, which is applied in the field of sensor calibration, can solve the problems of incompatibility, etc., and achieve the effects of wide compatibility, cost reduction, and connection harness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

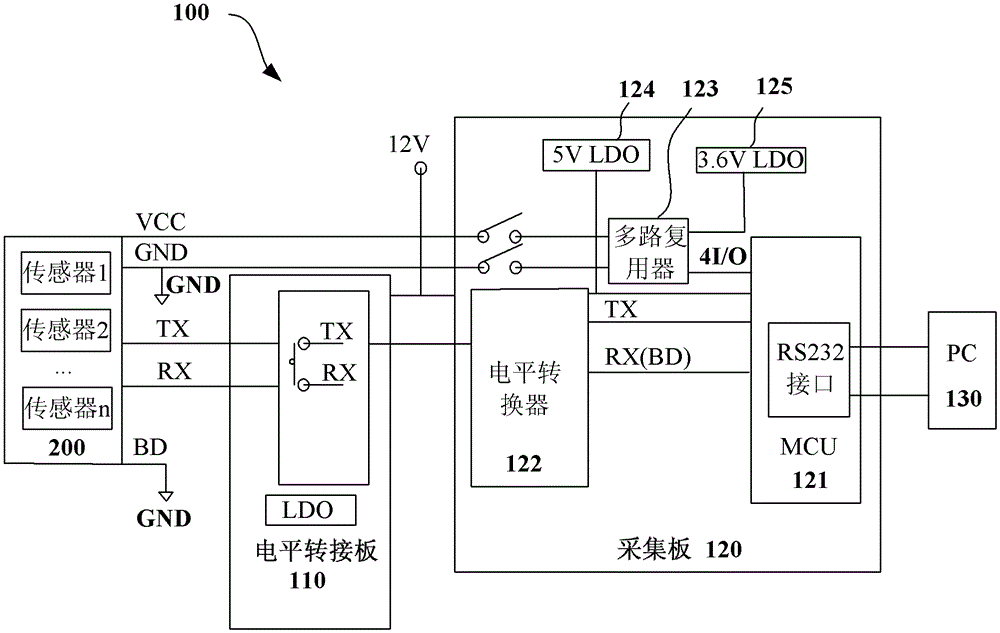

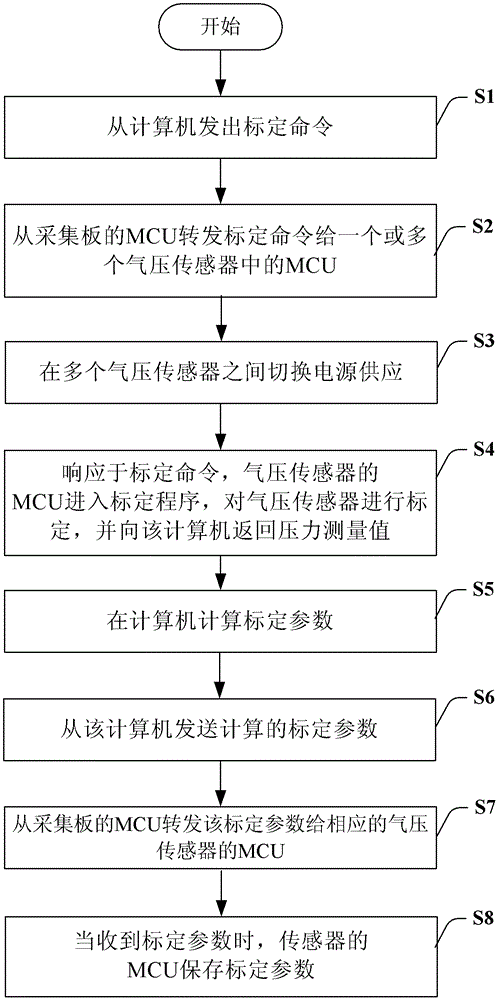

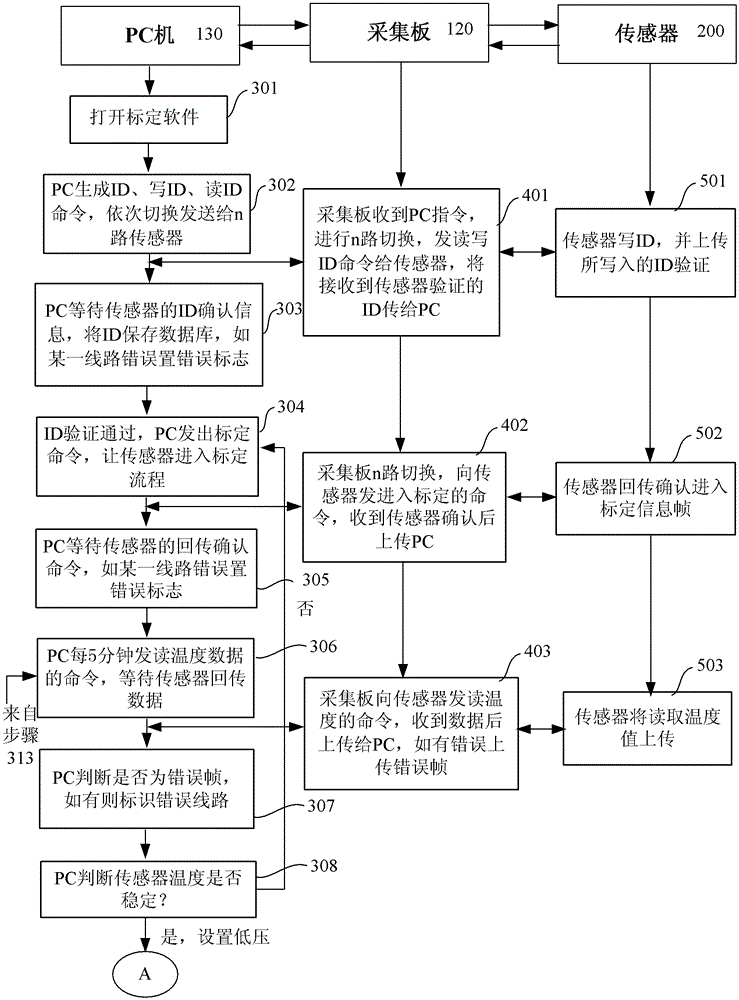

[0028] figure 1 An air pressure sensor calibration device according to an embodiment of the present invention is shown. refer to figure 1 As shown, the sensor calibration device 100 includes a pressure box (not shown in the figure), a high and low temperature box (not shown in the figure), a level adapter board 110 , an acquisition board 120 and a computer (PC) 130 .

[0029] N (n is a positive integer) sensor products 200 to be calibrated are placed in the pressure box. The pressure tank can provide the pressure required for calibration of each sensor 200 . The pressure box has a plurality of tube socket feet, which are used to connect with the lines that need to be led out from the sensor product 200 . These tube socket pins can lead out the wiring harness from the pressure box to meet the docking requirements of the sensor 200 .

[0030] The pressure box is placed in a high and low temperature box. The high and low temperature box can provide three temperature points o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com