Automatic spring plate assembling device of high-frequency data lines

A high-frequency data line and automatic assembly technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve problems such as waste of manpower and hidden quality problems, and achieve the effect of saving manpower and improving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

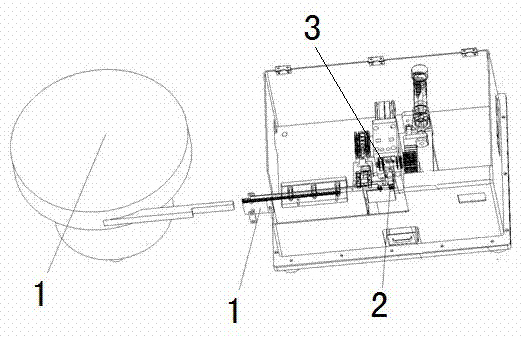

[0008] like figure 1 As shown, the present invention is realized in this way, and it includes feeding device 1, automatic assembly shrapnel device 2, infrared optical fiber sensor 3, the feeding port of feeding device 1 is connected to automatic assembly shrapnel device 2, and the automatic assembly shrapnel device 2 An infrared optical fiber sensor 3 is provided to sense the arrival of the shrapnel in the feeding device, and another positioning cavity of the automatic assembly shrapnel device 2 is placed with a SATA data line to be loaded with the shrapnel, and another infrared fiber optic sensor 3 senses the SATA data line to be loaded with the shrapnel. data line.

[0009] The feeding device refers to sending the metal shrapnel to the predetermined position by vibrating the plate, leveling the vibration of a certain frequency and adding the relevant mechanical structure.

[0010] The automatic assembly shrapnel device means that when the metal shrapnel is sent to the prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com