An inner needle seat structure for a safe self-destruction syringe

An inner needle seat, self-destructing technology, applied in the field of medical devices, can solve the problems of increased assembly difficulty, poor stability of the working state of the syringe, complicated mold opening process, etc., achieves outstanding substantive features, simplifies manufacturing processes, and reduces manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

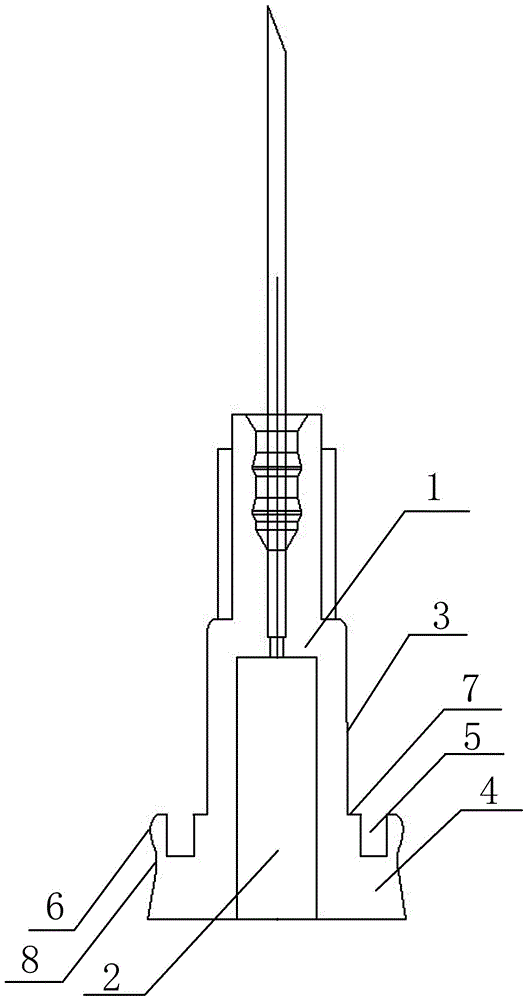

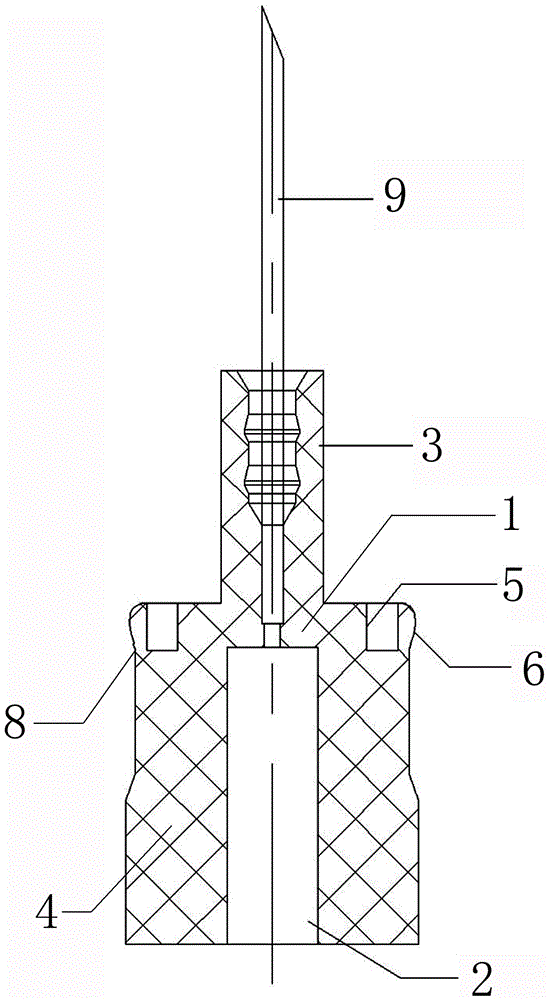

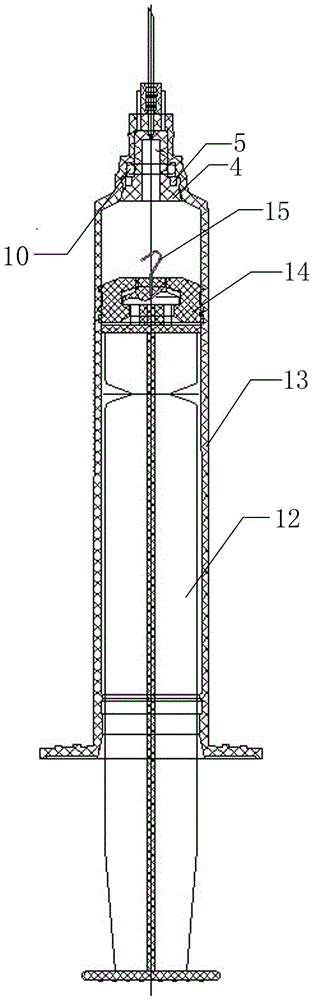

[0027] The present invention is an inner needle seat structure for a safety self-destruct syringe, such as figure 1 As shown in , it is a structural schematic diagram of the first embodiment of the present invention, which mainly includes an inner needle holder body 1, and a pull-back locking chamber 2 is provided at the lower end of the inner needle holder body 1, which is different from the prior art in that: the inner needle holder The body 1 is provided with a needle tube base 3, which is composed of an elastic sealing limit base 4 integrated with the needle tube base 3. The two are integrated into a single structure. An annular step 7 or an annular slope is formed between the base 3 and the elastic sealing limit base 4, and an "O"-shaped sealing rubber ring 10 is sleeved on the annular step 7 or the annular slope, and the elastic seal The surface of the limit base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com