Multipurpose flange correcting jig device

A multi-purpose, flange technology, applied in the field of auxiliary calibration tools, can solve the problems of poor calibration quality, high labor intensity, low work efficiency, etc., and achieve the effect of reducing calibration time, improving calibration quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, the present invention is further described:

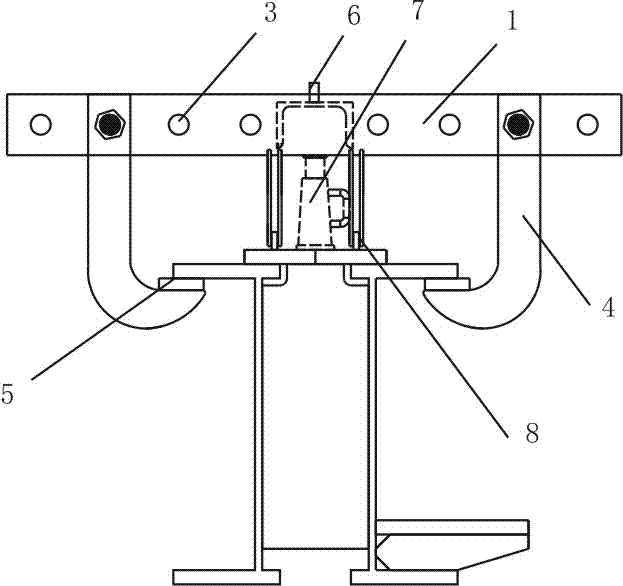

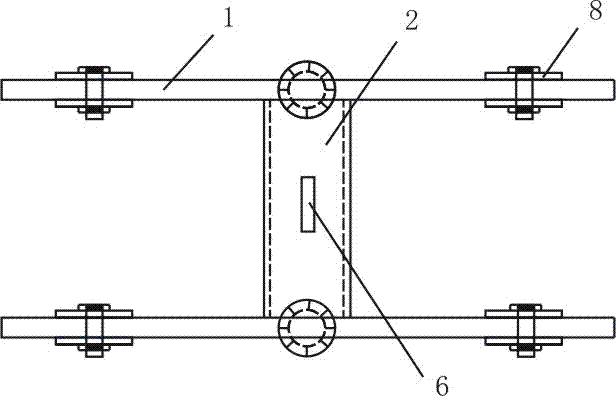

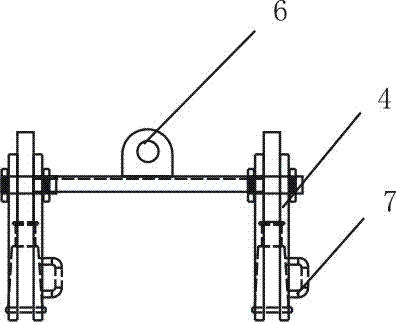

[0022] Such as figure 1 figure 2 image 3 The shown multi-purpose flange correction tire frame device includes a group of parallel side strips 1 of the same size. On the mounting holes 3 on both sides of the side strip, correcting hooks 4 are installed symmetrically, and on the contact surface between the correcting hooks 4 and the components to be corrected, there are also pads 5 of the same size, so Said connecting block 2 lower surface is also equipped with road wheels 8.

[0023] In this embodiment, the connecting block 2 is a channel steel structure, and the opening of the channel steel is downward.

[0024] In this embodiment, the upper surface of the connection block 2 is also welded with lifting lugs 6 .

[0025] In this embodiment, the distance between the mounting holes 3 near the two sides of the side bar 1 is less than 60 mm, and the distance between the holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com