Forming mould for SD (secure digital) card

A technology for forming molds and cavities, which is applied in the field of SD card production equipment, can solve problems such as increased production costs, uneven flow, and high technical difficulty in consistency, so as to reduce the degree of influence and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

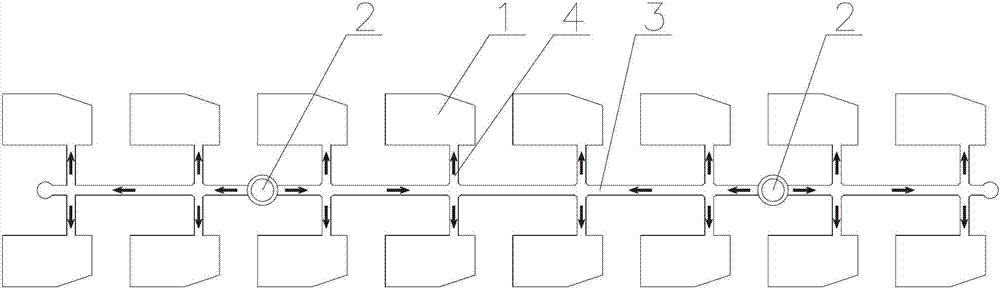

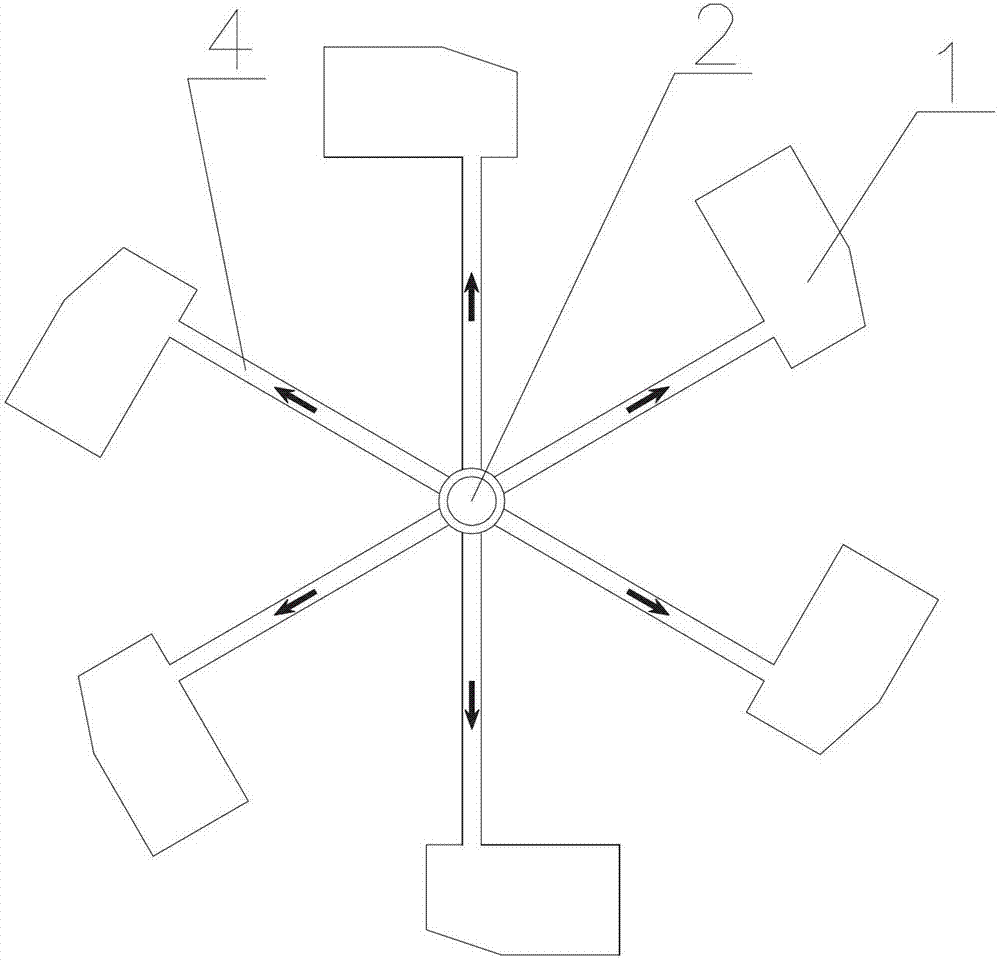

[0012] A kind of SD card molding die, includes several groups such as figure 2 In the pouring unit shown, each pouring unit includes a mold cavity 1, a sprue 2, and a runner 4 corresponding to the cavity 1 one by one. One end of all the runners 4 is connected to the sprue 2 after converging. The other end radially extends outward from the sprue 2 , and the cavity 1 communicates with the outwardly extending end of the runner 4 .

[0013] Specifically, in each pouring unit, the number of cavities 1 is four, six, eight, ten, etc., preferably six or eight.

[0014] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also possibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com