Method in reeling of fiber webs and reel-up

A technology of coiling device and fiber web, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., and can solve the problems of complex, expensive and inflexible prices of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description and drawings, unless otherwise stated, the same reference numerals refer to similar components, and it should be understood that these examples are open to modification in order to adapt to different uses within the framework of the present invention and conditions.

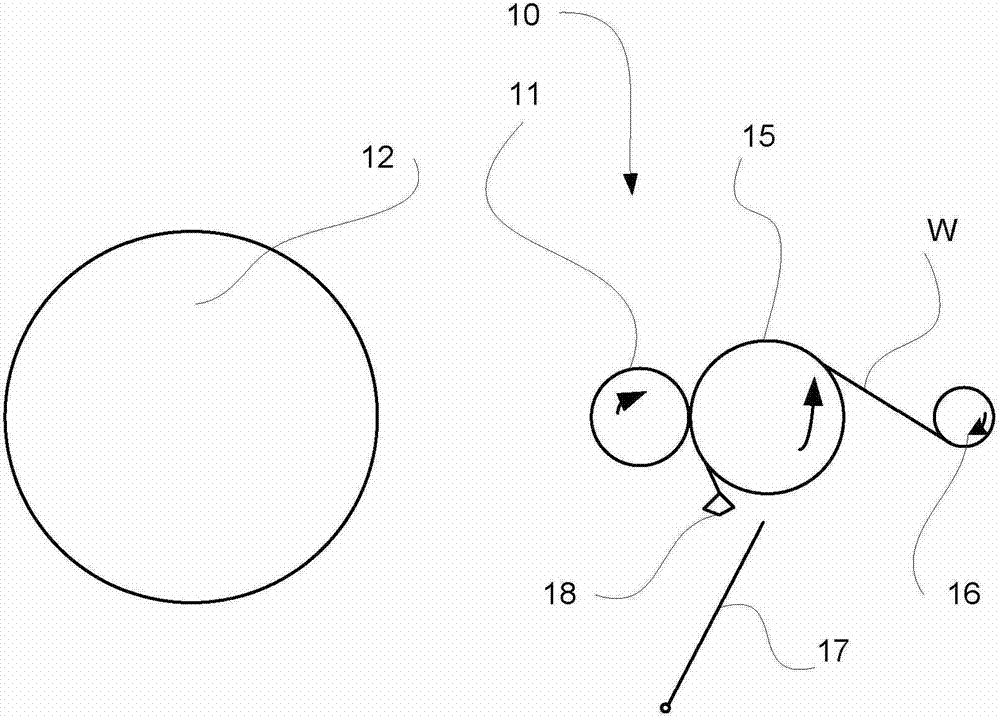

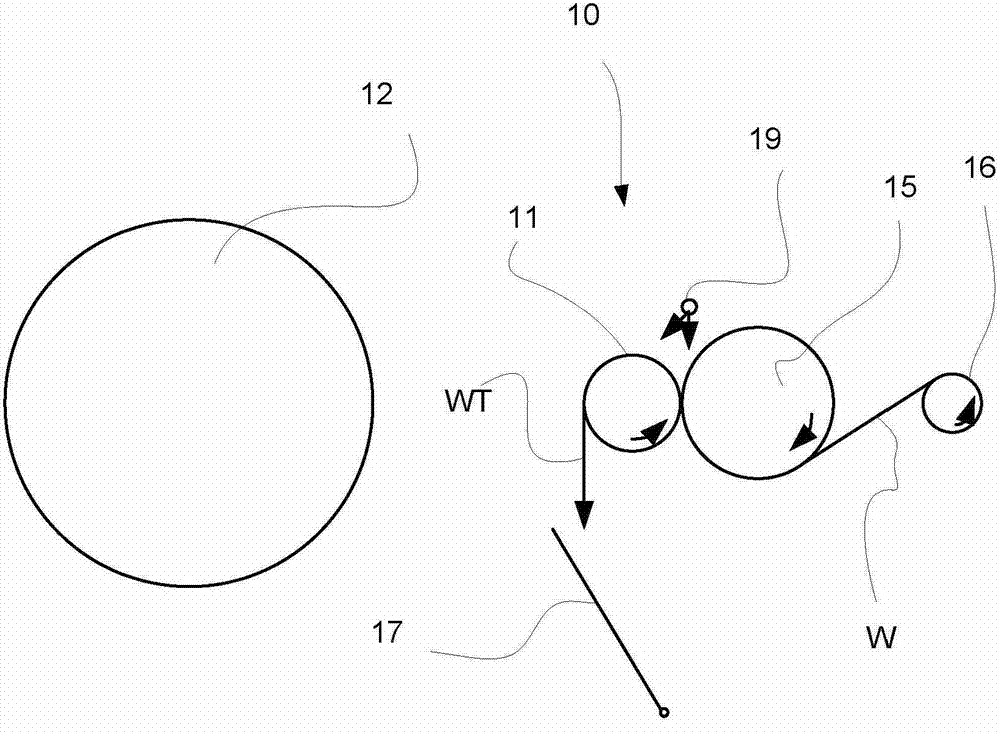

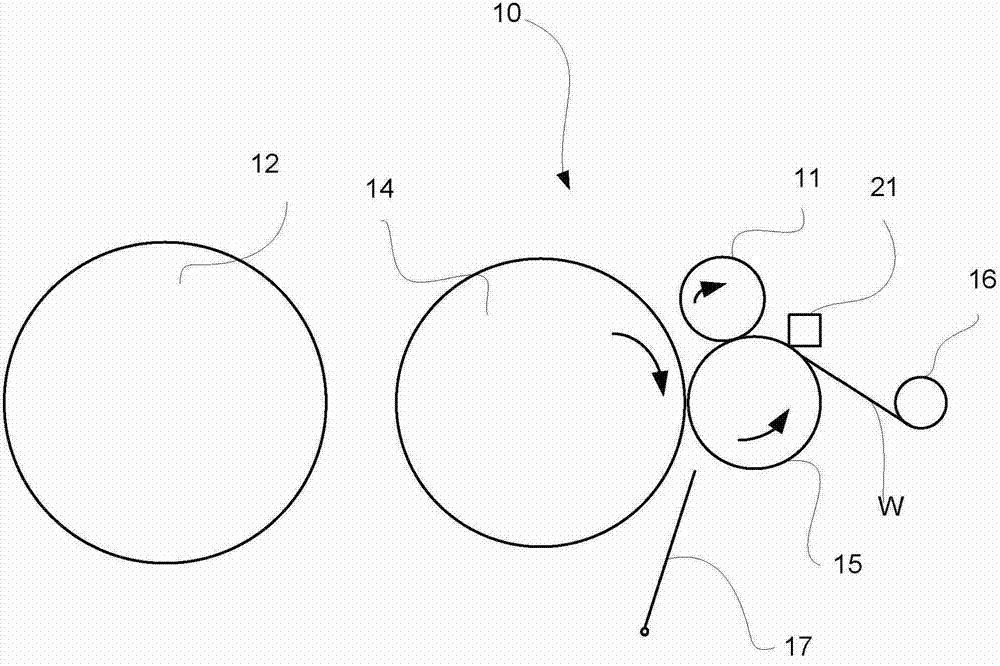

[0026] The coiling device 10 is schematically shown in the figures. In the reel-up device 10, the full-width fiber web from a previous processing step (e.g. from the dryer section of a fiber web machine) The material is wound around the winding shaft 11 to the parent roll 12. From a tenter roll 16 a fibrous web W is directed to a reel-up device 10 . In the figures, the directions of rotation of the mandrel 15, the take-up shaft 11 and the tenter roll 16 are indicated by arrows in the corresponding figure elements.

[0027] Figure 1A The reel-up is shown schematically in a threading phase with a typical upper draw, in which the start of the fibrous web W is guided from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com