Electronic control valve

An electronically controlled valve and solenoid valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of stuck in the working position, bumped staff, hidden dangers, etc., and achieves safe and reliable manual unloading sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

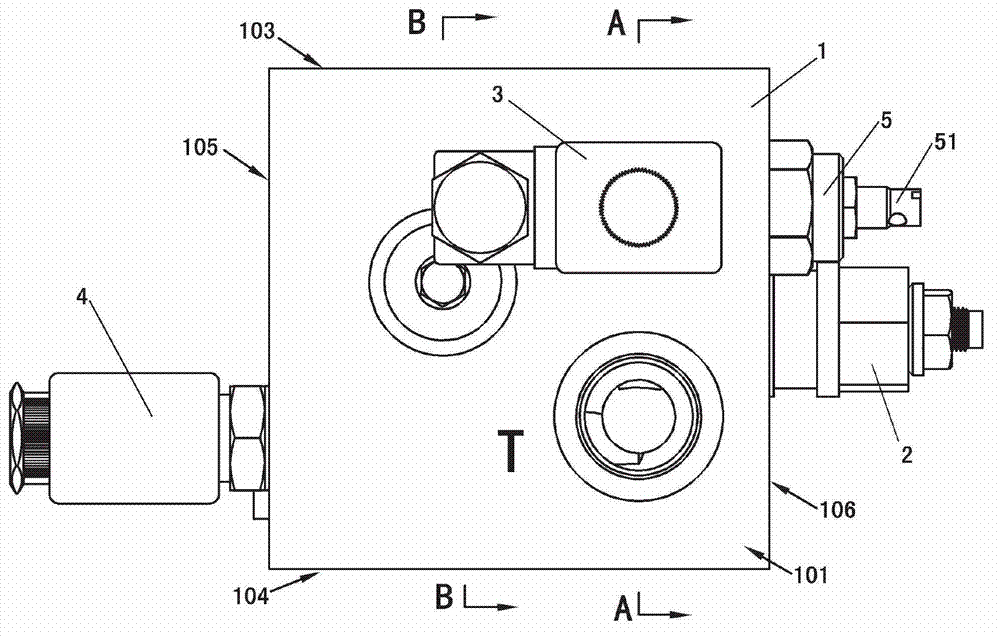

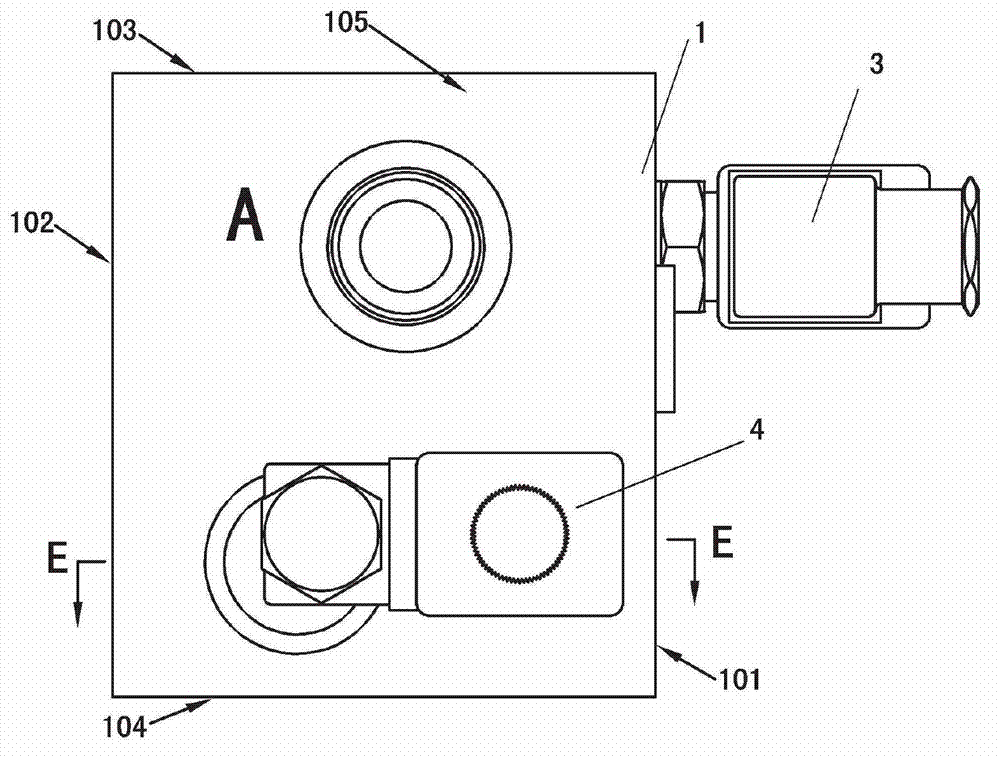

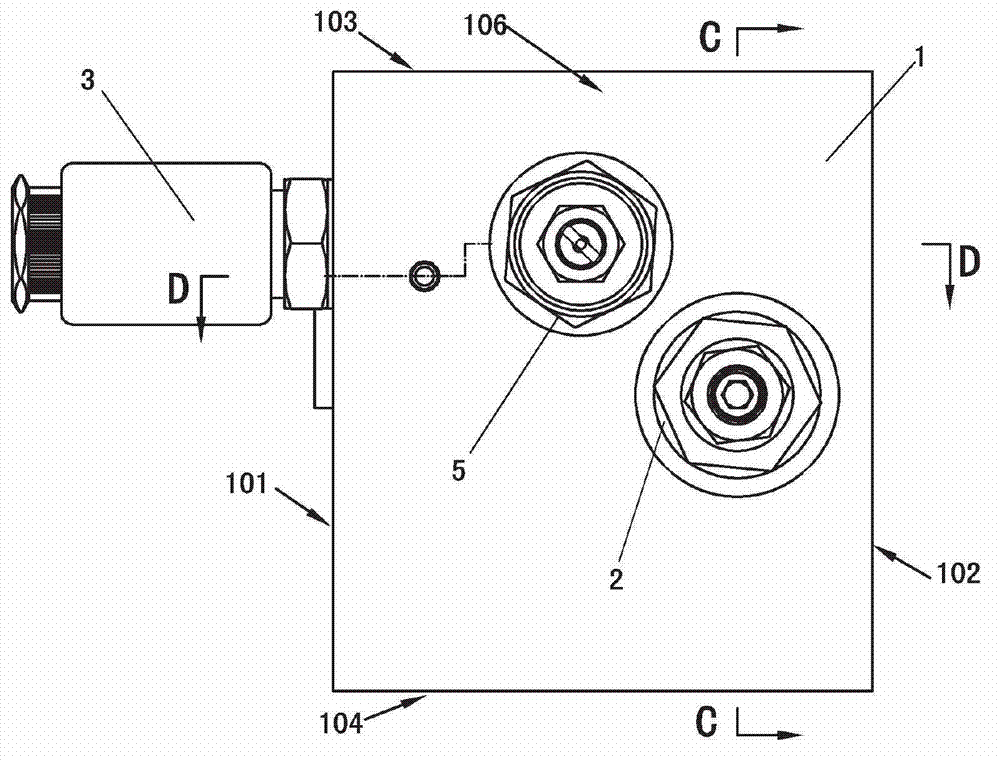

[0027] see attached picture figure 1 ~ attached Figure 10 , an electric control valve, including a valve body 1, the valve body 1 is provided with a safety valve 2, a first solenoid valve 3 and a second solenoid valve 4, and the valve cavity in the valve body 1 is provided with a stop valve 5, The first logic valve 6 and the second logic valve 7; the cut-off valve 5 includes a manual operating rod 51, and the end of the manual operating rod 51 protrudes outside the valve body 1; on the valve body 1 There are also oil inlet P, oil return port T and working oil port A. When the pump / motor is used as a pump, both the first solenoid valve and the second solenoid valve are powered off, the first logic valve is used as a one-way valve, the pump directly supplies oil to the oil cylinder, the weight rises, and the hydraulic energy is converted into potential energy; At this time, because the second solenoid valve is powered off, the second logic valve is closed, and the oil return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com