Fluid sand carrying experimental device

An experimental device and fluid technology, applied in the direction of wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of oil layer pollution, oil well production reduction, complex fluid flow rate, etc., and achieve good sand carrying effect and optimization The effect of the swabbing parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

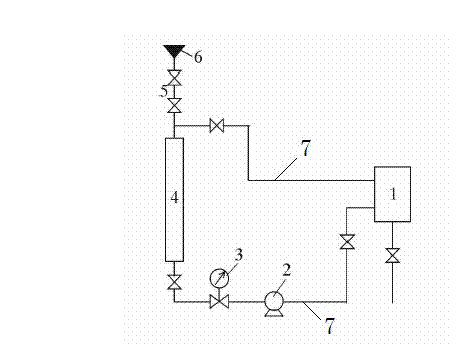

[0009] combined with figure 1 , to further describe the present invention:

[0010] The present invention is mainly composed of a water tank 1, a centrifugal pump 2, a test tube 4, a sand adding pipeline 5, a sand adding funnel 6, and a pipeline 7. The water tank 1 is connected to the centrifugal pump 2 and the test tube 4 through the pipeline 7, and the test tube 4 is connected to the sand adding tube. Pipeline 5, sand-filling pipeline 5 is connected to sand-filling funnel 6, and the joint between test tube 4 and sand-filling pipeline 5 is connected to water tank 1 through pipeline 7; flowmeter 3 is arranged between centrifugal pump 2 and test tube 4.

[0011] During the experiment, the foam fluid was poured into the water tank. Due to its low density, small filtration loss, good sand-carrying performance and strong drainage ability, the foam fluid can be widely used in drilling, completion, and Workover and oil and gas well stimulation measures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com