Engine Integrated Cooling System

A technology for engines and heat dissipation fans, which is applied in the direction of engine components, combustion engines, machines/engines, etc., and can solve the problems of unfavorable engine comprehensive heat dissipation, reduced engine efficiency, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

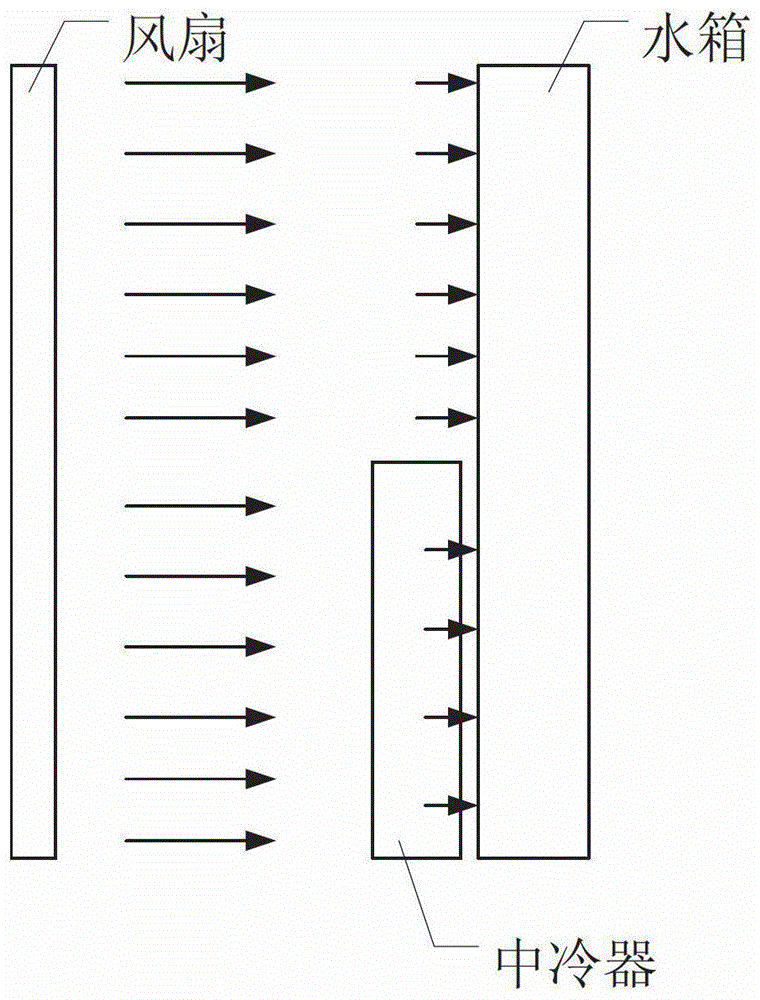

Embodiment 1

[0019] In this embodiment, the intercooler and the water tank are separately arranged. A fan system can be set for the two systems respectively. The target temperature t of the heat dissipation of the water tank preset in the fan controller 1 and the target temperature t of the intercooler 2 , the temperature detection device respectively detects the water temperature t 1 ’ and temperature t 2 ’ sent to the fan controller via the CAN bus. According to t 1 with t 1 ’, t 2 with t 2 ’ to calculate the appropriate fan speed. For example, when the detected temperature of the water tank or the intercooler has reached the target water temperature or air temperature, the fan controller located at the water tank or the intercooler judges that heat dissipation is not needed, and the water tank fan or the intercooler fan does not start; otherwise, the water tank fan or The intercooler fan is activated; if multiple fans are installed at the water tank or intercooler, the temperat...

Embodiment 2

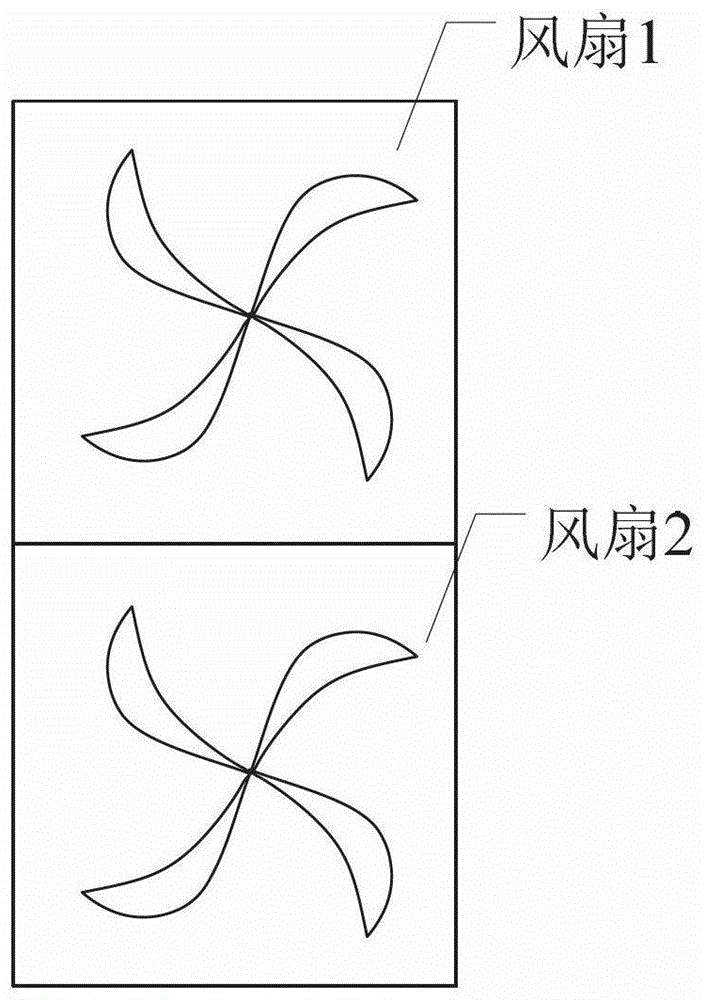

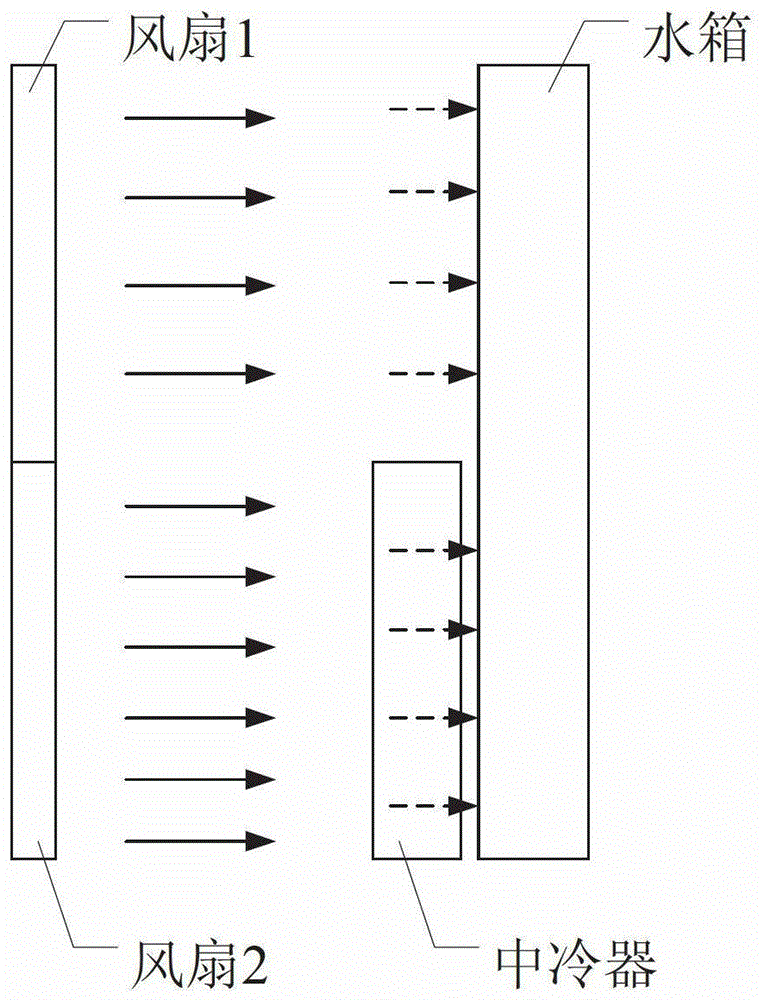

[0021] In this embodiment, the intercooler and the water tank are arranged overlappingly, such as image 3 shown. At this time, only one fan system can be set for the intercooler and the water tank, and the fan system is composed of fan 1 and fan 2, such as figure 2 shown. According to the comparison between the detected temperature of the intercooler and the water tank and the preset temperature, the fan is controlled to start and stop. The temperature detection device located in the water tank and the intercooler will set the water temperature t 1 ’ and temperature t 2 ’ are sent to each fan controller respectively, and the controller presets the target water temperature t 1 , the target temperature t 2 , if t 1 '> t 1 , then the fan group 1 located at the water tank starts, if the air temperature t 2 '> t 2 , located in the intercooler cooling fan group 2 to start, the cold air of fan 2 can also dissipate heat to the water tank after passing through the intercoole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com