Thermal pressing machine dedicated to tatami

A kind of technology of hot press and tatami, applied in the field of hydraulic machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

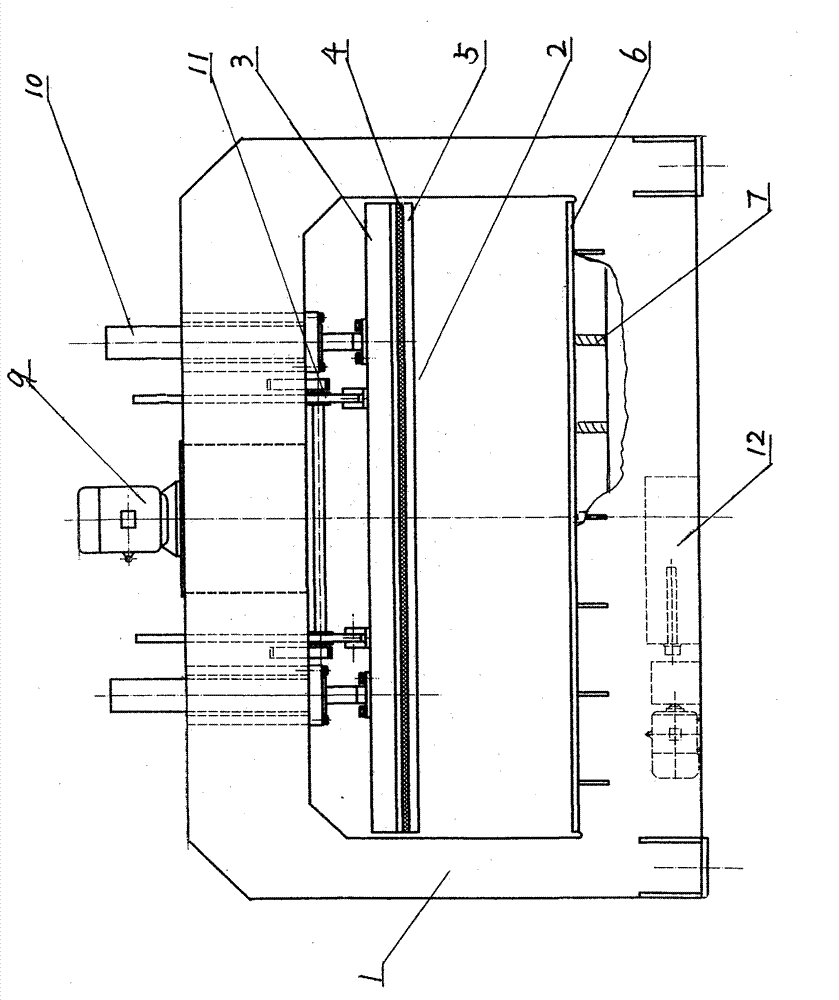

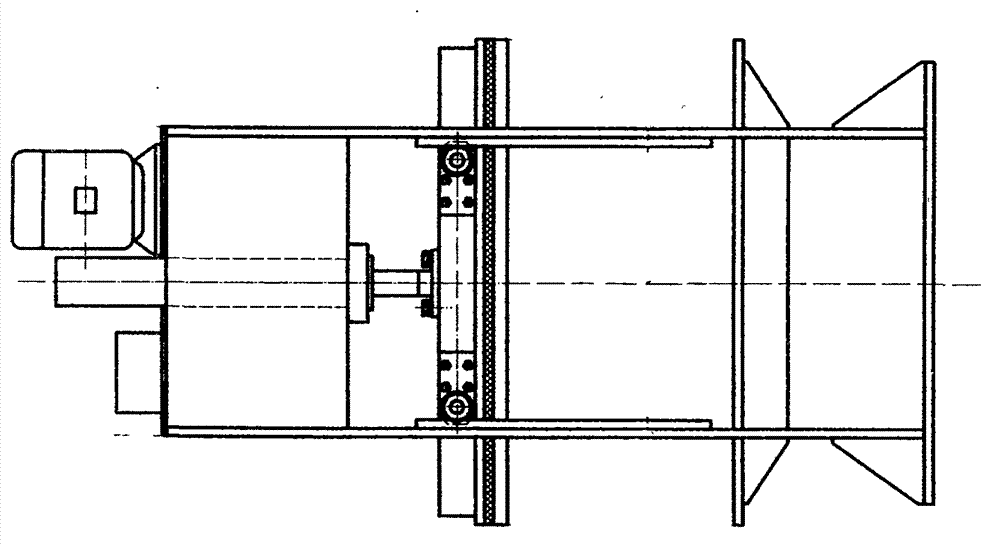

[0013] Attached above figure 1 , 2 , 3 provides a specific embodiment of the present invention, which will be further described below.

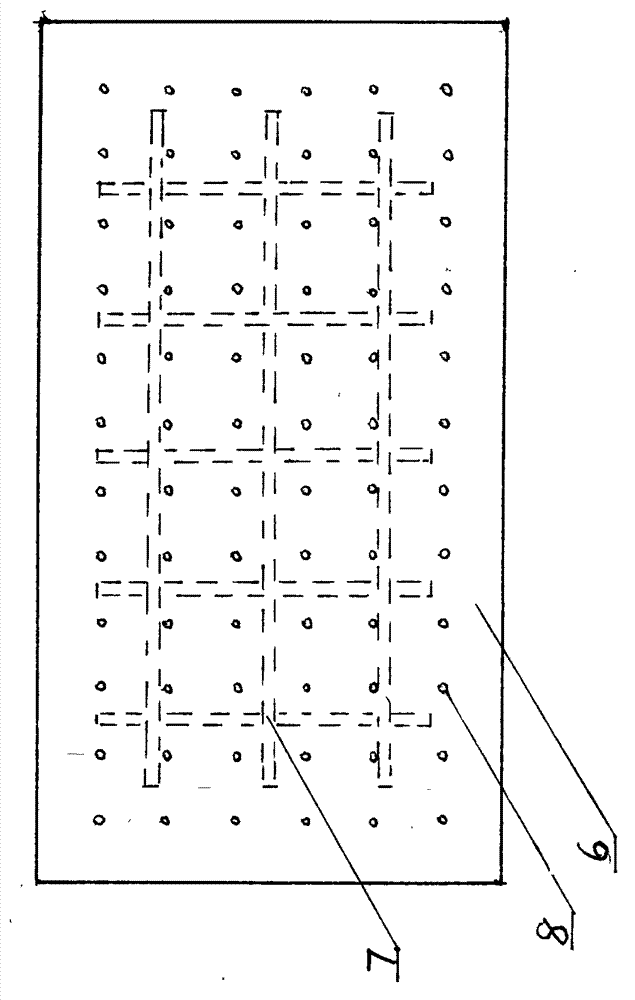

[0014] The hot press machine for tatami mats includes a frame 1, an upper movable platen 2 connected with a hydraulic cylinder 10, a lower fixed platen 6 fixed to the frame, a hydraulic system 9, an oil heating system 12 and an electric control system . The upper movable pressing plate 2 includes a pressing plate 3, a heat shield 4 and a hot pressing plate 5. The upper movable pressing plate 2 is located in the central compression space of the frame, and can move up and down under the action of an oil cylinder for hot pressing. The lower fixed platen 6 is fixed with the frame bottom, and the pressed workpiece is placed on the lower fixed platen to be pressed. The back side of the lower fixed platen 6 has heat dissipation and ribbed plates 7 arranged in a grid shape, as attached figure 1 and 3 As shown, it is used to increase the compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com