Electric heating system for fluid transportation pipe and pipe assembled with electric heating system

A technology for transportation pipes and heating systems, which is applied in the direction of electric heating devices, piping systems, transportation and packaging, etc., and can solve the problems of rising overall risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Now, the present invention will be specifically described.

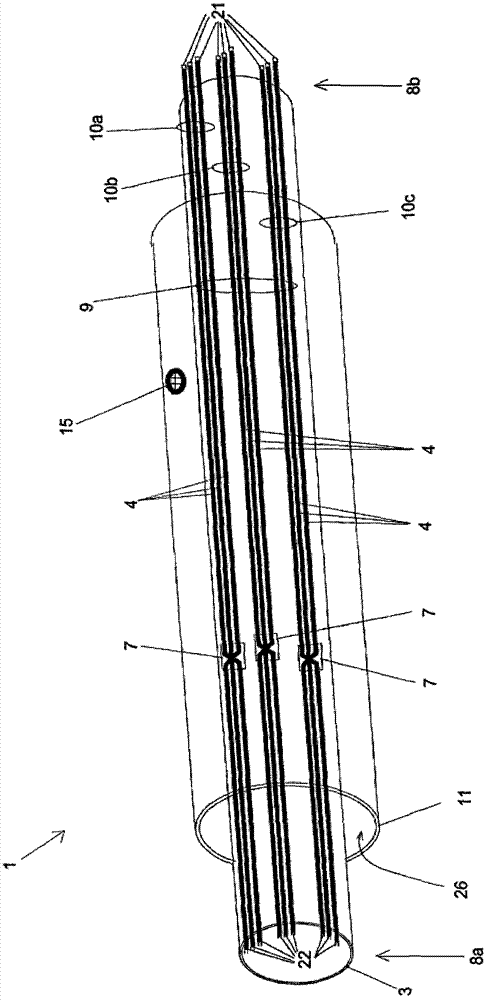

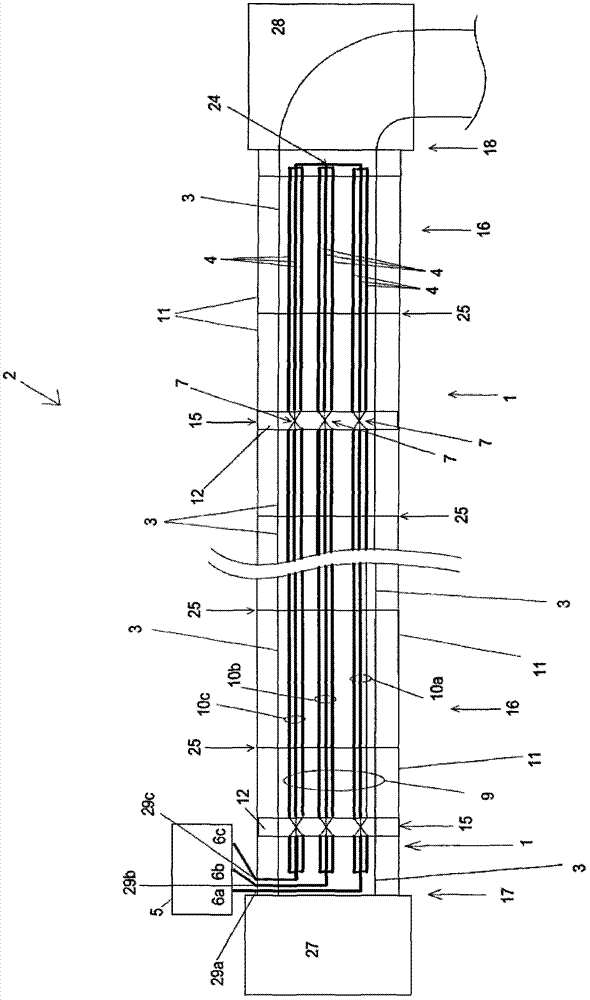

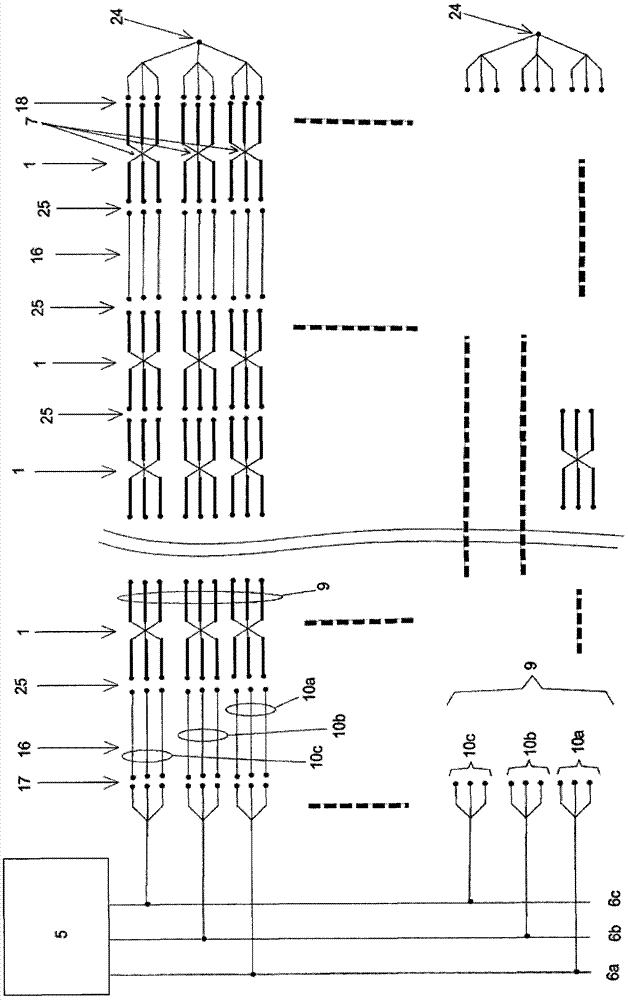

[0057] figure 1 Section 1 is shown assembled with other sections to form a pipe 2 for transporting fluids such as hydrocarbons. This section comprises a first casing 3, or inner casing, through which the fluid to be transported flows.

[0058] The second bushing 11 is arranged around the first bushing 3 and keeps a certain distance therefrom. The bushing 3 and the bushing 11 delimit an annular region 26 . The annular area 26 accommodates, for example, the heating system and the thermal insulation of the first sleeve 3 . The first sleeve 3 can be made of metal, and the second sleeve 11 can also be made of metal. The first casing 3 and the second casing 11, for example, can be made of steel or other metals. The second bushing 11 is explicitly shown to show the heating system, no insulation is shown in figure 1 middle.

[0059] A tube provided with a single sleeve could conceivably have a heating wire pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com