Method for establishing statics model of extra-large double-row four-point contact ball bearing

A static model, four-point contact technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of accurate bearing load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structural parameters, material parameters and load conditions of a certain type of extra-large double-row four-point contact ball bearing are known as follows:

[0041] d m =2215mm, D W =44.45mm, α 0 =45°, d c =69mm, r i = r e =23.34mm, Z =128×2, v =0.3, E =207 GP a , F a =250 kN , F r =130 kN , M =1800 kN m

[0042] The specific establishment process of the static model of the pitch bearing is as follows:

[0043] Step 1. Establishment of geometric model

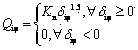

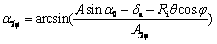

[0044] Under the premise of given structural parameters, material parameters and load parameters of the pitch bearing, before the bearing is loaded, the formula for the distance between the centers of curvature of the inner and outer ring grooves of any contact pair of rolling elements is:

[0045]After the bearing is loaded, the formula for the distance between the curvature centers of the inner and outer ring grooves of four contact pairs at any rolling element position becomes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com