Bird's-nest device for transformer substation

A technology for substations and bird's nests, applied in switchgear, electrical components, manipulators, etc., can solve problems such as low flexibility and effectiveness, weeds are easy to float to other operating equipment, and it is difficult for gram rods to enter and clean up. Achieve the effect of avoiding grounding or short-circuit tripping accidents, avoiding the reduction of power supply reliability, and effective removal and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

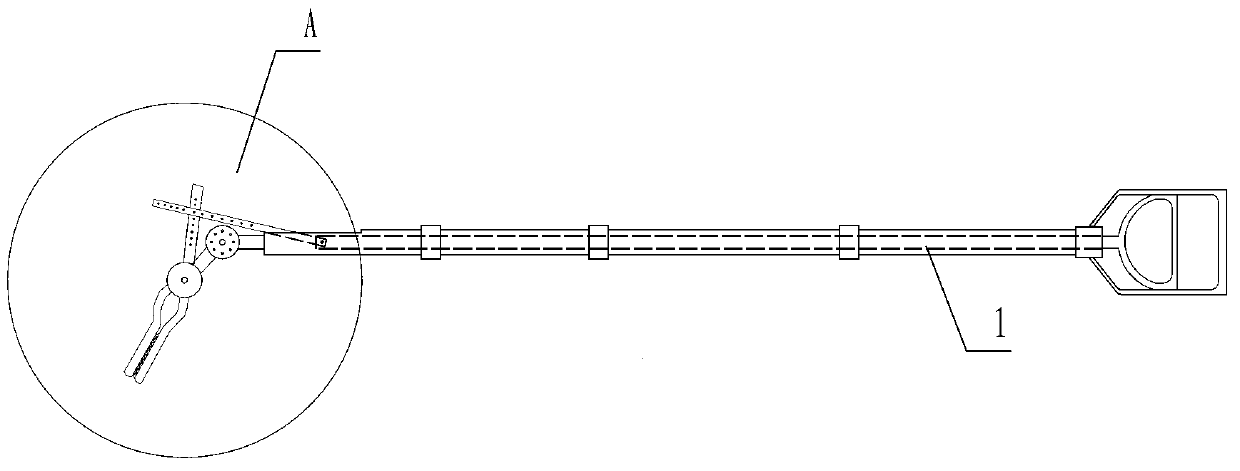

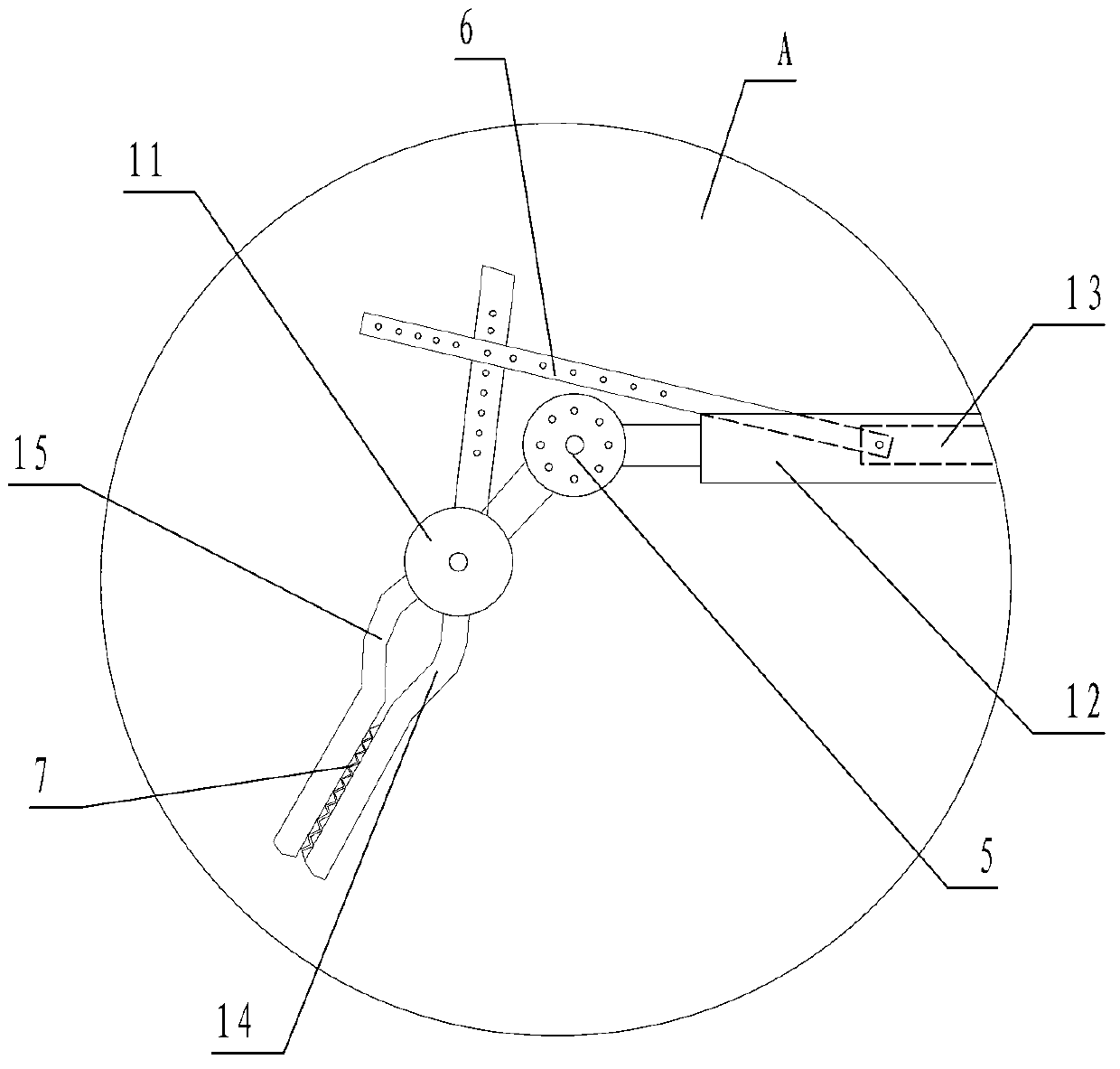

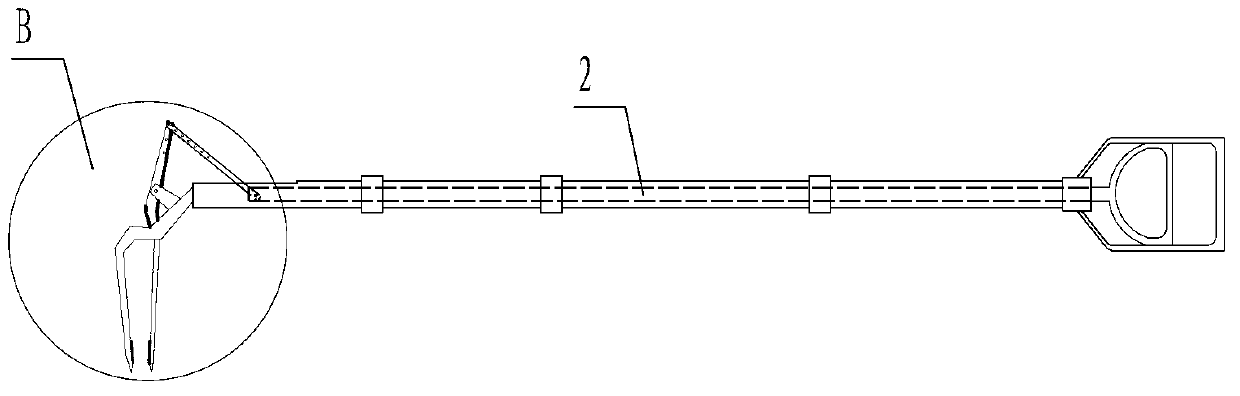

[0042] a kind of like Figure 1-8 The substation bird's nest removal device shown includes a horizontal clamp type manipulator 1 such as figure 1 , 2 , vertical clamp manipulator 2 such as image 3 , 4 , rake manipulator 3 such as Figure 5 , net bag receiving device 4 such as Image 6 .

[0043] The horizontal clamp type manipulator includes a horizontal clamp head 11, an insulating sleeve 12 and an insulating pull rod 13. The insulating sleeve is set outside the insulating pull rod, and the insulating pull rod reciprocates relative to the insulating sleeve. The horizontal tong head includes dynamic tongs and static tongs, and the dynamic tongs and static tongs are interlaced and hinged together. The dynamic tongs 14 and static tongs 15 located on the upper side of the hinge point are working heads, and the dynamic tongs and static tongs located on the lower side of the hinge point are the working heads. The static tongs serve as connecting ends, and the insulating slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com